Five-axis machining machines can quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way to manufacture difficult parts with multi-angle features.

As the cutting tool moves towards the tip or edge of the workpiece, the cutting state gradually deteriorates. To maintain optimal cutting conditions, a rotating table is required. If the irregular plane is to be completely machined, it is also necessary to rotate the table several times in different directions. The deflection of the tool in the five-axis CNC machining machine can avoid the situation that the cutting speed of the center point of the ball end mill is 0, and obtain better surface quality.

The five-axis CNC machine tool performs sidewall processing through the deflection of the spindle head, which does not require multiple parts clamping, which effectively reduces the positioning error, improves the processing accuracy, and shortens the manufacturing chain. In aerospace, automotive and other fields, with high flexibility, high precision, high integration and complete processing capabilities, it can well solve the precision and cycle problems of complex parts processing in the process of new product development, greatly shorten the development cycle and improve the quality of new products.

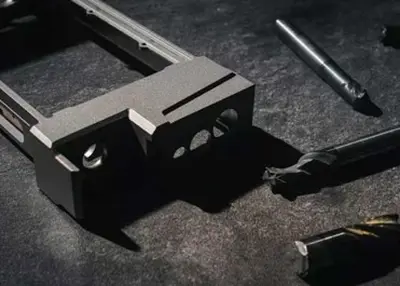

For the processing of impellers, blades and steep sidewalls of molds, three-axis CNC machine tools cannot meet the processing requirements, while five-axis CNC machine tools can be controlled by the spatial attitude angle of the tool axis to complete such processing content. At the same time, short tools can be used to machine deep cavities, which can effectively improve the rigidity of the system, reduce the number of tools, avoid special tools, and expand the scope of use of general tools, thereby reducing production costs. For some inclined surfaces, five-axis CNC machining can use the tool side edge to complete the sidewall cutting of the part by circumferential milling, thereby improving machining efficiency and surface quality. The three-axis CNC machining relies on the layered cutting and subsequent grinding of the tool to approach the inclined surface.

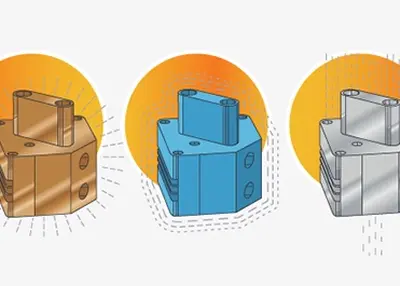

Five-axis CNC machining is often used to quickly complete complex prototypes or low-volume parts, machining precision parts from solid billets in a variety of industries, because they are often much stronger than parts made from multiple parts, using five-axis precision machining means you can speed up the manufacturing process by reducing setup time and machine features on different sides.

CNC milling operation with five-axis CNC machining speeds up the manufacturing process of complex precision parts, revolutionizing industry machining efficiency. It also allows designers to consider previously impossible or uneconomical designs, and quality parts that can be produced in solid billet, rather than cast workpieces with associated drawbacks. For example, impellers, extruder screws, turbine blades and propellers with demanding geometries can be machined from any solid material that can be machined using high-performance carbide tools. Almost any shape and geometry is possible.

As a professional China CNC factory, Richconn provides quality 5-axis CNC machining services at great prices. Feel free to contact at any time.

Waterborne Aluminum Powder Coating on(Nylon+Fiberglass )Composite Materials: The Innovative Path to the FutureAugust 8, 2023Waterborne aluminum powder coating on nylon+fiberglass composite materials is an ingenious technology that combines nylon and fiberglass to give a unique metallic appearance. This innovative coating t...view

Waterborne Aluminum Powder Coating on(Nylon+Fiberglass )Composite Materials: The Innovative Path to the FutureAugust 8, 2023Waterborne aluminum powder coating on nylon+fiberglass composite materials is an ingenious technology that combines nylon and fiberglass to give a unique metallic appearance. This innovative coating t...view Precautions for Using CNC TurningApril 25, 2023Turning is a cutting method that uses the rotation of the workpiece relative to the tool on a lathe to perform cutting operations. CNC turning allows the workpiece rather than the tool to provide most...view

Precautions for Using CNC TurningApril 25, 2023Turning is a cutting method that uses the rotation of the workpiece relative to the tool on a lathe to perform cutting operations. CNC turning allows the workpiece rather than the tool to provide most...view CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view

CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view The Complete Guide to Aerospace Fasteners 2023August 24, 2023The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of ai...view

The Complete Guide to Aerospace Fasteners 2023August 24, 2023The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of ai...view Narrowing Down Material Options For CNC Machining.October 17, 2023Choice is good. In most cases, the greater the selection, the greater the chance of finding just the right thing. But a large selection also means that finding the perfect material becomes more complicated.view

Narrowing Down Material Options For CNC Machining.October 17, 2023Choice is good. In most cases, the greater the selection, the greater the chance of finding just the right thing. But a large selection also means that finding the perfect material becomes more complicated.view Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view

Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view

EN

EN

ru

ru