In the global processing and manufacturing industry chain, China's industrial scale and industrial workers have made it a leader in the CNC machining industry. The country has a large number of CNC machining and rapid prototyping workshops and professional engineers, catering not only to the domestic market but also to the international industry. In this article, we'll explore the reasons for outsourcing CNC machining parts to China and dive into the factors to consider when choosing a precision machining manufacturer in the country.

The size of China's CNC machining manufacturing industry has been showing a strong growth trend in the past few years.

China's CNC machining manufacturing industry has formed some industrial clusters, such as in Zhejiang (Jiaxing), Jiangsu (Kunshan, Suzhou), Guangdong (Shenzhen, Dongguan) and other places, with an integrated CNC industry chain, including CNC machine tool manufacturing, CNC system research and development, CNC tool manufacturing, etc. Among them, Shenzhen is mainly CNC machining, and Dongguan is centered on mold processing and manufacturing. In particular, Dongguan Chang ‘an is known as the 'mold capital'.

China's CNC manufacturing industry has made significant progress in terms of technical level. It has not only made great breakthroughs in the R&D and manufacturing of CNC machine tools, but also made significant progress in CNC programming, automated production lines, and intelligent manufacturing. Among them, the most representative heights are Foxconn, Lux share Precision, which are OEM for Apple, BYD in the automotive industry, etc., which basically cover the processing and manufacturing level of the middle and high levels.

Of course, these are all on the basis of the world's most comprehensive processing equipment (machine tools), the largest number of engineers, and the most complete supply chain.

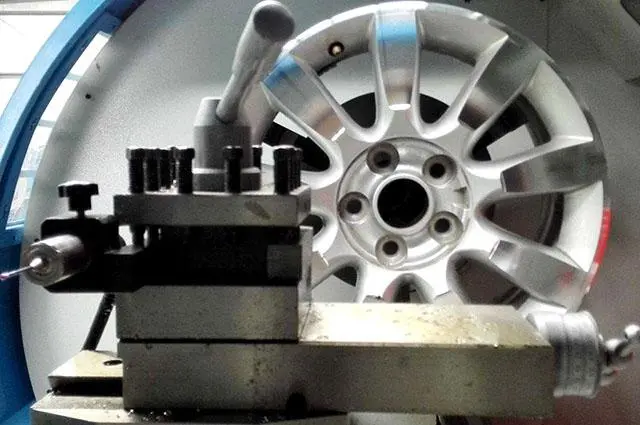

CNC machining technology is widely used in various manufacturing industries, including aerospace, automotive, electronics, medical equipment, energy, and more. In these areas, CNC technology can improve production efficiency, reduce costs, and enable high-precision machining of complex parts.

In the automotive industry, molds, injection molding, cables, fasteners, etc. are all locally produced, processed, manufactured and assembled;

The medical industry has molds, electronics, injection molding, high-precision parts processing, etc., which concentrate 50% of China's supporting enterprises;

The energy industry includes automotive batteries (70%), energy storage (60%), photovoltaics, solar energy, etc.;

Have you ever wondered why a company would turn to outsourcing their CNC machining of components? In fact, you can gain several advantages if you do this.

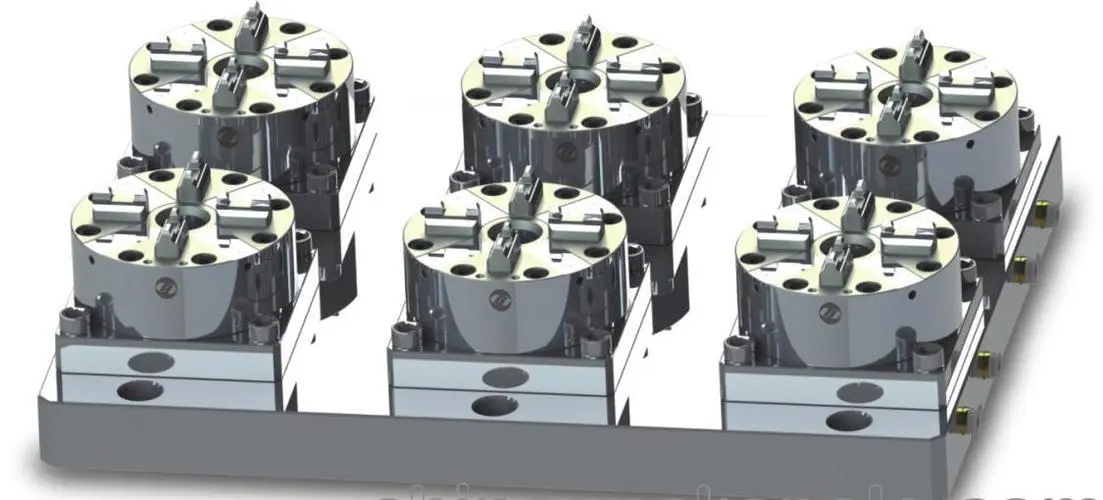

Outsourcing CNC machining allows companies to gain access to advanced industrial machining technology that they may not have in-house, or it can be costly or non-existent due to factors such as industry migration. As a global leader in manufacturing, China is equipped with state-of-the-art CNC machines and tools, providing companies with the opportunity to leverage cutting-edge technology for their machining needs.

Outsourced CNC machining allows companies to scale up production based on demand. When your business is starting out or innovating or expanding, you need suppliers, you need to add suppliers to make your business more competitive, manufacturers in China often have a variety of capacities to handle large volumes of products, providing businesses with the flexibility to ramp up production when needed, without having to make major infrastructure investments.

Successfully executing a CNC machining project requires a lot of expertise and experience. Richconn has 20 years of CNC machining capabilities, supporting more than 500 customers, 20 professional engineers, and more than 10 experts in various industries. Of course, CNC machining is a difficult process that requires specialized operational training, so organizations that adopt the technology in-house must have experienced, CNC-trained operators. By outsourcing to these manufacturers, companies have access to experts who can handle their CNC machining needs efficiently and effectively.

Cooperating with a Chinese rapid prototyping company strengthens and expands on the benefits of cooperating with an external CNC machining service provider. Many Chinese CNC machining companies, like Richconn, invest in state-of-the-art equipment and maintain high standards of quality.

Compared to other traditional manufacturing countries, China is known for its competitive manufacturing speed and price. This is mainly due to China's relatively low labor costs and relatively complete supply chains. Reducing manufacturing costs can help businesses reduce overall production expenses and increase profitability.

China has a well-established manufacturing ecosystem with abundant resources and a robust supply chain network. This means that suppliers can easily source raw materials and components, which helps reduce lead times and costs. Additionally, China has developed an efficient logistics infrastructure, making it easier and more cost-effective to transport goods internationally.

By now, it seems that you are interested in locating a CNC machining service in China. It would be worth giving it a shot and requesting a quote to determine the price. Here are some crucial considerations that can assist you and your business in identifying a suitable CNC machining partner in China.

When searching outsourcing possibilities for quick prototyping and production, one of the most critical factors in selecting a manufacturing partner is determining whether their certifications correspond with the type of product you would like to produce. Look for a service provider that has relevant certifications, such as ISO 9001, which demonstrates their commitment to quality management systems.

A CNC machining company has established quality control processes in place to ensure the accuracy and precision of the machined parts. At Richconn, we offer a comprehensive and cutting-edge quality control workflow to ensure that your prototypes and products meet the highest standards.

Consider the provider's experience in CNC machining and their ability to handle projects of various complexities. Look at their track record and ask for samples or case studies of similar projects they have completed.

To ensure that a potential CNC machining company in China can meet the quality standards of a given part or product, first provide a prototype or drawing of the part. Prototypes of parts will enable customers to ensure that a particular CNC machining company will be able to produce parts that meet the standards as scheduled. If the prototype is machined and delivered within three days, the customer can quickly decide whether to continue working together.

Evaluate the provider's communication skills and responsiveness. Clear and prompt communication is vital for smooth collaboration and project management. Ensure that they have good customer service and can address any concerns or issues you may have.

Our highly skilled and experienced engineering team speaks with our prospective clients to ensure that you receive the best CNC machining services for your project.

One of the most important factors you should consider is whether the service offers budget-friendly manufacturing services. This means that the service should provide competitive pricing for their CNC machining services, ensuring that it aligns with your budget requirements. It is recommended to compare prices and quotes from different CNC machining services in China to find the one that offers the most cost-effective solution without compromising on quality.

We recognize and value your right to privacy. When using our services, we will do our best to ensure that your personal information is properly protected. Here's our commitment to privacy:

Information Collection: We collect only the minimum necessary information to provide our services. We do not collect, use, or share personal information that is not related to the Services.

Use of Information: We will only use your personal information to the extent necessary to provide our services. We will not use your information for purposes other than those unrelated to the Services, nor will we provide it to any unauthorized third parties.

Information Security: We maintain strict security measures to protect your personal information from unauthorized access, use, or disclosure. We are committed to ensuring the confidentiality and integrity of our data.

Transparency: We will be transparent with you about how we collect, use and process your personal information. You can always be aware of our privacy policy and practices.

User Control: We respect your control over your personal information. You have the right to choose whether or not to provide personal information and to access, correct, or delete your information at any time.

Compliance: We comply with applicable privacy regulations and legal requirements to ensure that our privacy practices are compliant with those set forth in the regulations.

At Richconn, we provide a cost-effective production process as the cost of material and feature expenses are considerably lower.

By the end of this passage, I trust that you are now aware of the advantages of collaborating with a CNC machining service in China, whether for fast prototyping or personalized production. Furthermore, you should have gained insights into the key factors to consider when selecting a Chinese company to work with.

To wrap up, I would like to recommend Richconn, a popular platform that specializes in rapid prototyping and custom manufacturing. They offer cost-effective prices, reliable design for manufacturing analysis, and professional engineering advice. Simply upload your design files and specify your requirements, and they will respond to you within just an hour.

Interested? Click the button below and give it a shot today

What Does Color Flaw Detection Mean?October 19, 2023Color flaw detection is a method of non-destructive testing, it is a surface inspection method, mainly used to detect such as the naked eye can not identify the cracks and other surface damage, such as the detection of stainless steel material near the surface defects (cracks), porosity, porosity, delamination, unwelded and unfused and other defects (also known as PT detection).view

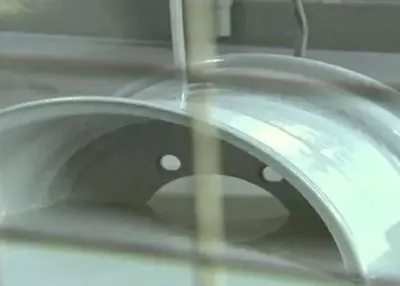

What Does Color Flaw Detection Mean?October 19, 2023Color flaw detection is a method of non-destructive testing, it is a surface inspection method, mainly used to detect such as the naked eye can not identify the cracks and other surface damage, such as the detection of stainless steel material near the surface defects (cracks), porosity, porosity, delamination, unwelded and unfused and other defects (also known as PT detection).view Electrophoresis Plating in Corrosion ResistanceJanuary 5, 2024When it comes to protecting metal objects from corrosion, electrophoresis plating is a game-changer. This process not only enhances the appearance of the metal but also provides a robust shield agains...view

Electrophoresis Plating in Corrosion ResistanceJanuary 5, 2024When it comes to protecting metal objects from corrosion, electrophoresis plating is a game-changer. This process not only enhances the appearance of the metal but also provides a robust shield agains...view Application of 5-Axis Machining Center in High-Speed Blower Impeller ManufacturingMarch 24, 2023With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture ...view

Application of 5-Axis Machining Center in High-Speed Blower Impeller ManufacturingMarch 24, 2023With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture ...view 7 Tips for Choosing a Right CNC Machine ManufacturerSeptember 7, 2023Some companies seek a quality precision manufacturer with the best matching services. Nowadays, there are lots of CNC manufacturers to choose from. The problem is how to pick out the right CNC manufac...view

7 Tips for Choosing a Right CNC Machine ManufacturerSeptember 7, 2023Some companies seek a quality precision manufacturer with the best matching services. Nowadays, there are lots of CNC manufacturers to choose from. The problem is how to pick out the right CNC manufac...view CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view

CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view 5-Axis CNC Machining: Faster Speeds and Higher PrecisionJuly 27, 2023One of the ambitious goals of the manufacturing industry is to complete processing in one go: putting a piece of material into a machine tool, running a program, and finally obtaining a perfectly Mach...view

5-Axis CNC Machining: Faster Speeds and Higher PrecisionJuly 27, 2023One of the ambitious goals of the manufacturing industry is to complete processing in one go: putting a piece of material into a machine tool, running a program, and finally obtaining a perfectly Mach...view

EN

EN

ru

ru