A common question asked is, "How much will it cost me and how much will it cost to manufacture?" Everyone loves a bargain! Plus, we can judge the prices of our daily purchases - €5 for a liter of milk? No way!" But when it comes to custom components, whether made by CNC maching, 3d printing for manufacturing or injection molding, things get a little more complicated.

You can simplify it a bit by thinking about the big three factors: raw material, manufacturing time and fixed costs. Each of these factors contributes to a price as follows:

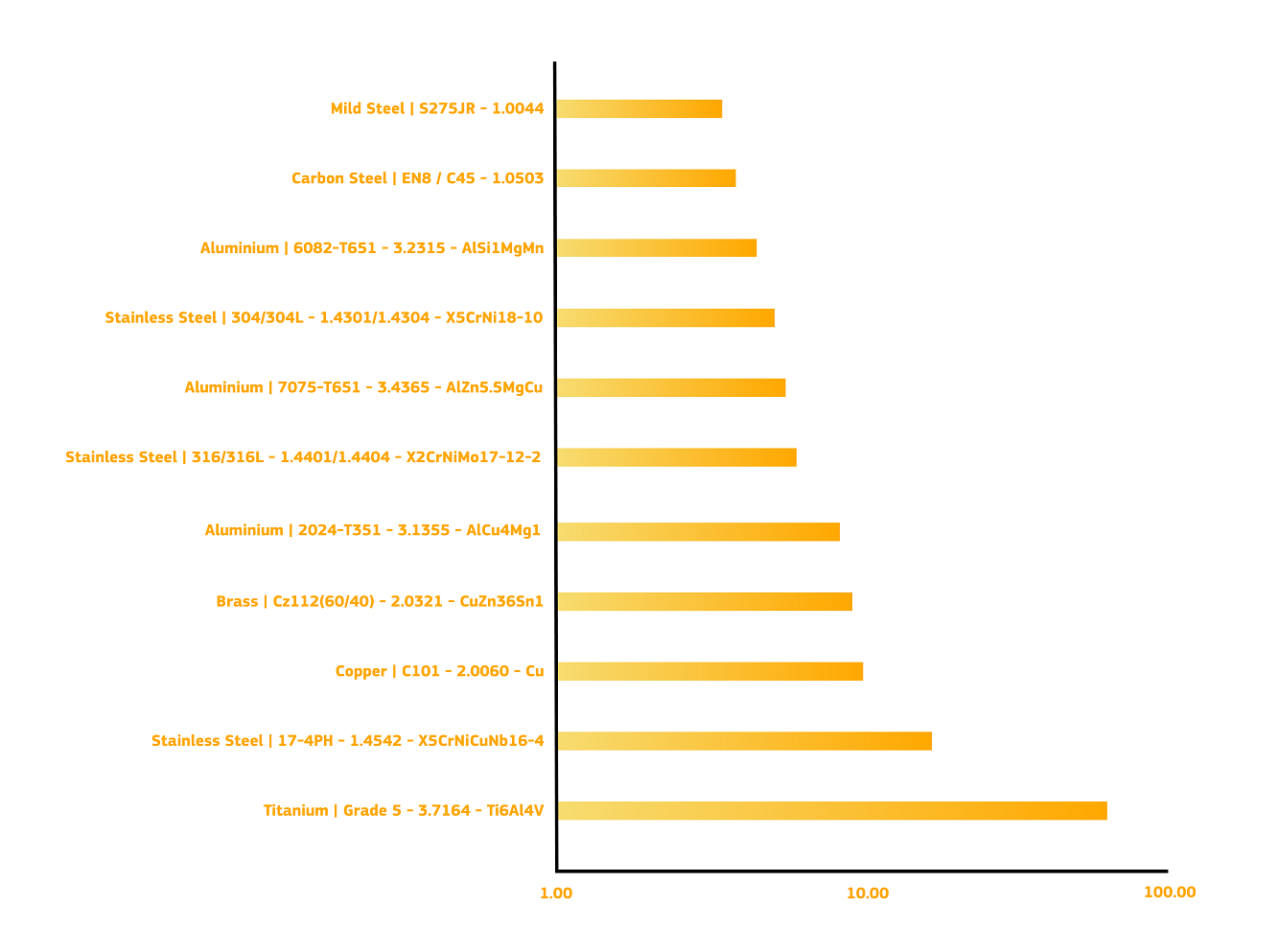

Figure – the relative raw material costs for metals and plastics

Metals: gold, silver, bronze - we all know that the scarcity of these metals and the refining costs (gray energy and manufacturing techniques) determine the raw material cost. The chart of relative metal costs holds few surprises - steel and aluminum are plentiful (Al6082 is our most common grade) and have the lowest raw material costs per kg (or pound). The middle of the chart shows the more specialized aluminum grades and stainless steels, which contain expensive alloying elements. At the bottom is titanium, which is surprisingly common but difficult to refine (which, along with corrosion resistance, also contributes to its high price).

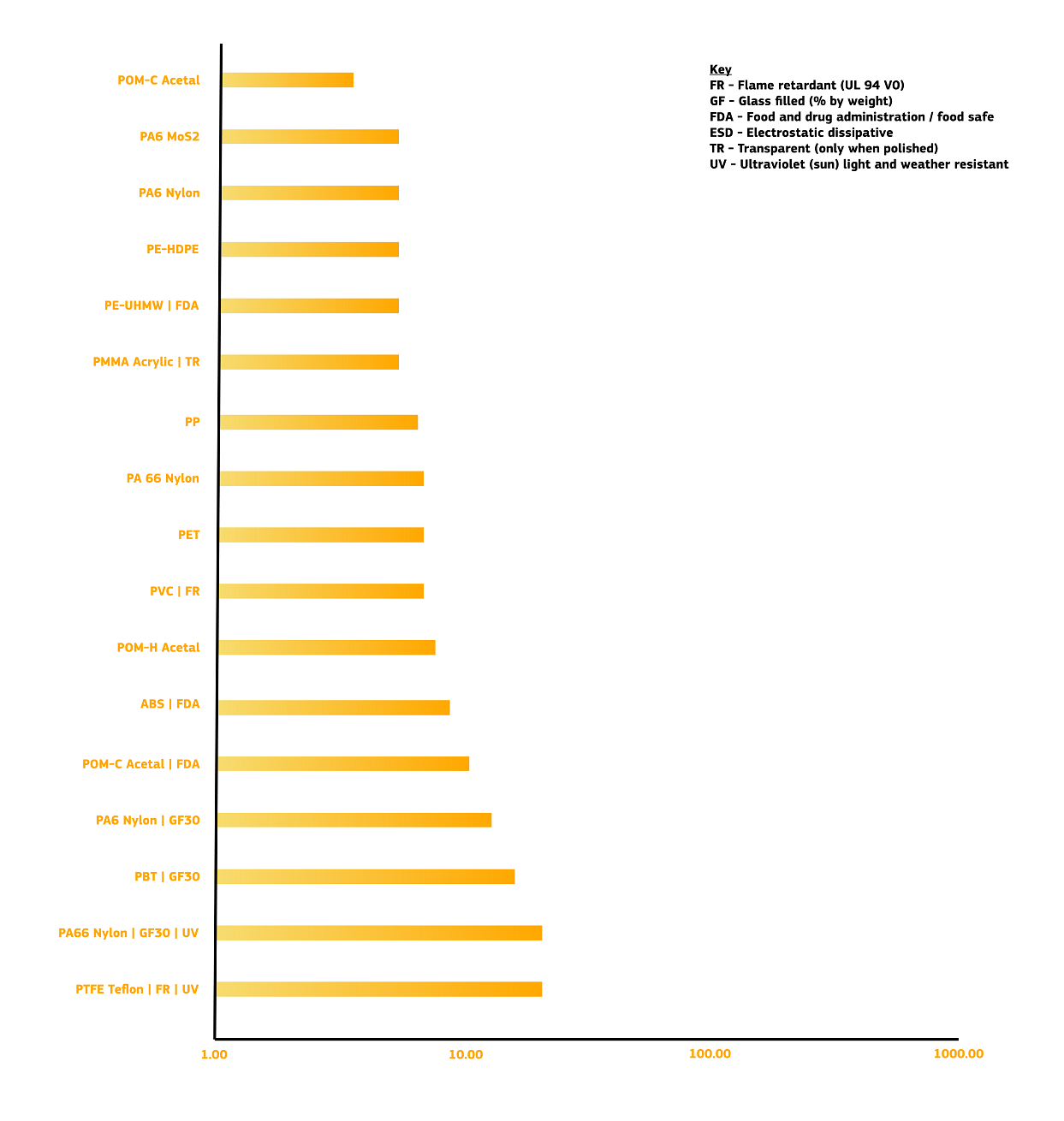

Fig. 2 - relative raw material costs for engineering grade plastics.

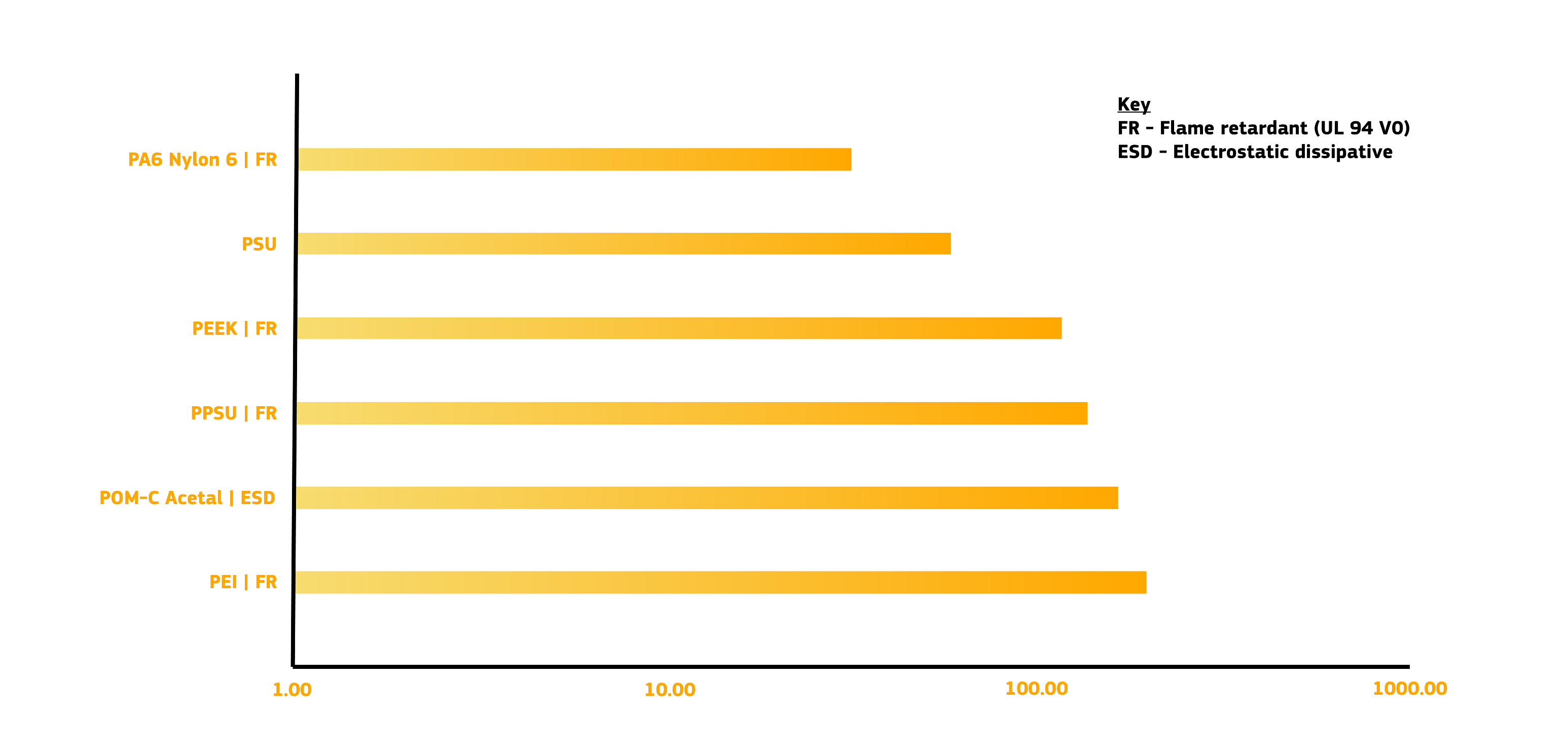

Fig. 3 - relative raw material costs for specialist plastics.

Plastics: Can look quite similar, but have an even more extreme price range.

Low cost per kg: Nylon (PA6), acrylic and ABS are common materials used in both injection molding and CNC components. However, there is one material that is both cheaper and performs better: Acetal (often called Delrin®) is an excellent general-purpose engineering plastic with good stability.

Medium Cost: Carbon fiber-filled materials cost about 50% more - the brittle, fragile carbon fibers combine with the tough plastic to create a composite material. This is stronger and more durable.

Special applications: The prices of these raw materials exceed that of titanium (£100/kg is possible), so it is worth checking if there is an alternative! In general, there is a specific requirement to be met: PC (polycarbonate) is so strong that it is used for bulletproof glass! PEEK - the first choice in Formula 1 and aerospace. Because it is stronger than some metals, plus UV and flame resistant, it will meet almost any requirement. PSU, PPSU, PEI are generally used in food and medical applications. POM-ESD is modified to be just conductive enough to prevent static discharge.

These are made up of machining time (and associated tool wear) and the time to make fixtures to hold the components securely. This also includes fixturing when machining is done from multiple directions.

We manufacture your part (digitally) and include the manufacturing costs in the price. In the process, we check to see if manufacturing is feasible and how long it will take. We can manufacture less complex parts the same day, but most quotes include a 3-day turnaround. The check is usually done automatically. An experienced engineer signs off on each quote. This usually takes less than an hour.

Of course, part complexity is the determining factor - smaller, more detailed features require smaller tooling and therefore take longer. The other factor is machinability.

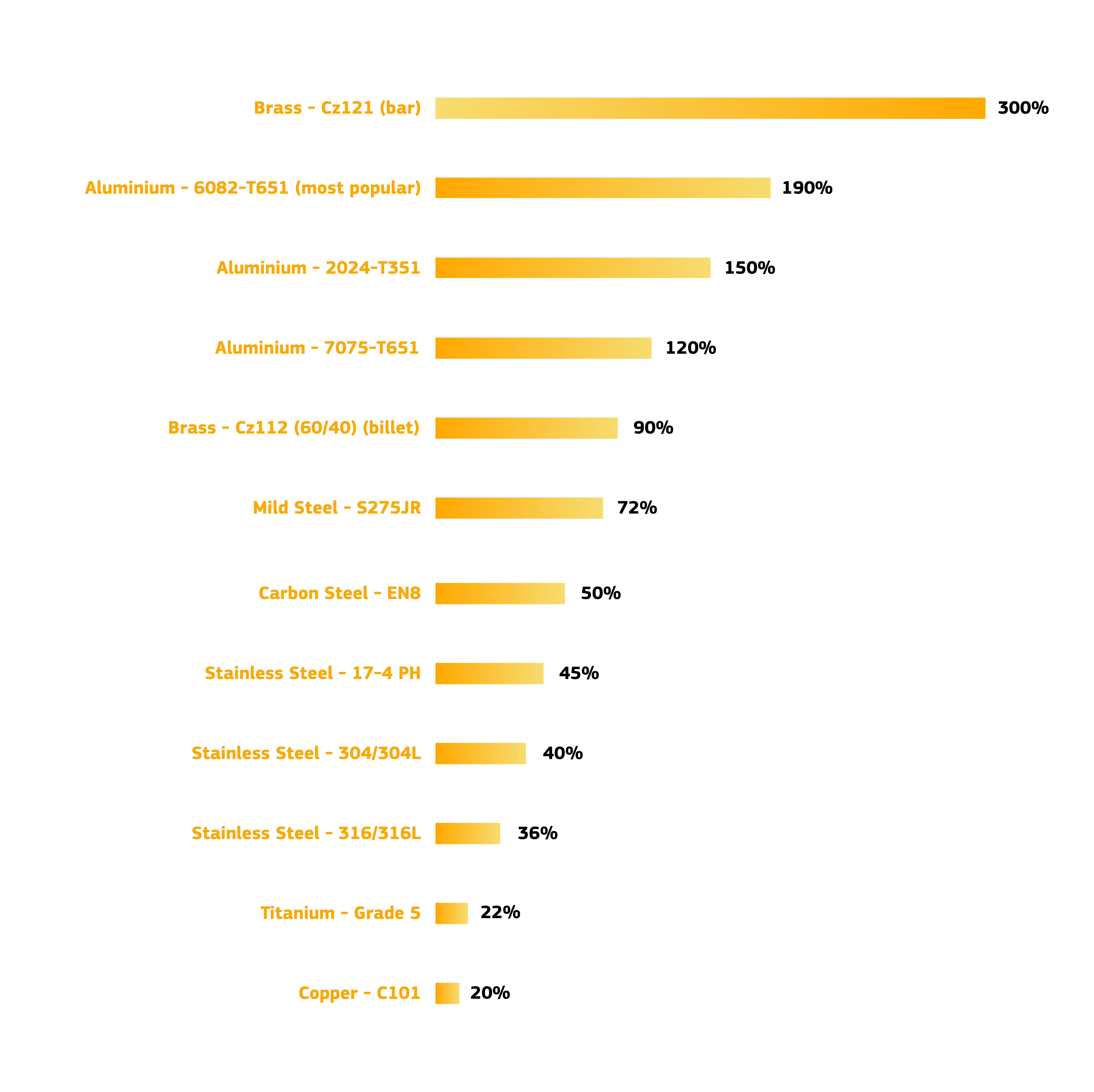

Figure: Machinability ratings - AISI metals (in % compared to carbon steel 1112) and plastics 1 to 20

Fig. 5 - machinability ratings, plastics 1-20 (best)

In general, plastics are softer and easier to work with - but too soft (as with PVC and PP) can be a challenge (polypropylene, which is used to make rope, among other things, exhibits this behavior when cut). The next best are the "soft" metals brass and aluminum 6082. Generally, the harder the metal, the more difficult it is to cut. Finally, copper is easily deformed - so avoid thin structures.

Reference: https://www.azom.com/article.aspx?ArticleID=4097

There are always additional costs. But often they are not "value-added" (do not directly contribute to the production of the part), but are necessary (and important): Packaging, measuring and testing, calibrating and setting up equipment, preparing work, preparing quotes, and communicating with customers.

One way to minimize these costs is through automation, such as robotics and autonomous machines designed for high volumes. This type of automation can reduce the unit price, but it comes with a cost known as non-recurring engineering (NRE) costs. In other words, this type of automation takes time to set up and can be inflexible. It is appropriate for high-volume manufacturing, but makes little sense for prototyping and initial production quantities.

That's why our automation is focused on the NRE and uses a digital approach. We don't need a 2D drawing because we automatically generate the machine code, inspection requirements, and part fixturing directly from your upload. The main advantage of this is that we can start manufacturing your 3D design within minutes of receiving your order. Another benefit is that we don't charge a setup fee. Of course, with each additional part, the price goes down, but we are very flexible in producing simple and complex one-offs or small batches.

So far, we have looked at physical characteristics - material, size and quantity. However, our precision machining services also includes invisible attributes: Speed and reliability.

All CNC components are manufactured in the China. Additive manufacturing is done in China. Our average CNC machining manufacturing time is 3 days.

And if you can wait 3 weeks or 3 months, there is a whole world of options available thanks to the wonders of modern transportation and global trade. The important thing is that you contrast "price and delivery" on a comparable basis. This brings us to the final point.

"Time is money," the saying goes, and your time is especially valuable. Whatever you design will have impact, and your customers want it now. We've helped design and manufacture prototypes of everything from better medical devices to more efficient electrical appliances to better transportation solutions.

It's likely that 10% more investment in solid prototyping and testing will result in a better product, but 10% delay (or say 10 days after a major product launch!) is most definitely a costly problem.

"Fail fast, fail often" was the quote from Thomas Edison, and he did, with over 9,000 prototypes! Dyson famously produced over 5,000 prototypes to perfect the cyclonic vacuum cleaner. Thanks to 3D CAD and digital tools, designers no longer have to test as much, but perhaps the balance has shifted too far? It really is that quick and easy to upload something.

Quality factors: components meet and exceed specified tolerance.

Service: Richconn provides information on material properties, design tips and thread selection

Advice: 3D design feedback is included with each quote, and our customer service team is happy to provide advice and information about the best manufacturing solution

Galvanneal vs Galvanized: Which Sheet Metal Material Is Right for Your Manufacturing Needs?March 22, 2024Galvannealed and galvanized steel are distinct types of sheet metal, produced through different processes and possessing unique properties. Read on to find out more!view

Galvanneal vs Galvanized: Which Sheet Metal Material Is Right for Your Manufacturing Needs?March 22, 2024Galvannealed and galvanized steel are distinct types of sheet metal, produced through different processes and possessing unique properties. Read on to find out more!view Safety Issues in CNC Turning TechnologyApril 25, 2023Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves,...view

Safety Issues in CNC Turning TechnologyApril 25, 2023Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves,...view How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view

How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view Powder Coating 101: What Is Powder Coating?August 14, 2023When seeking effective and durable finishing solutions for metal components, one term often comes up: "powder coating". The world of powder coating is full of mysteries. Whether you're c...view

Powder Coating 101: What Is Powder Coating?August 14, 2023When seeking effective and durable finishing solutions for metal components, one term often comes up: "powder coating". The world of powder coating is full of mysteries. Whether you're c...view Fundamentals and Techniques of Engineering DrawingsDecember 1, 2023Engineering drawings are a graphical language used to express engineering design ideas and details, and they are an important tool for engineers for design, manufacturing and maintenance. Engineering drawings follow a number of international or national standards and specifications to ensure the accuracy, consistency and readability of engineering drawings.view

Fundamentals and Techniques of Engineering DrawingsDecember 1, 2023Engineering drawings are a graphical language used to express engineering design ideas and details, and they are an important tool for engineers for design, manufacturing and maintenance. Engineering drawings follow a number of international or national standards and specifications to ensure the accuracy, consistency and readability of engineering drawings.view Understanding machining tools: types, uses and selectionNovember 1, 2023Machining tools are vital tools in manufacturing, used to cut, chip, grind and shape a wide range of materials, from metals to plastics to wood. Different tool types are used for different processes and materials to meet a variety of machining needs. Below are five common types of machining tools that are used in a wide range of manufacturing and processing applications.view

Understanding machining tools: types, uses and selectionNovember 1, 2023Machining tools are vital tools in manufacturing, used to cut, chip, grind and shape a wide range of materials, from metals to plastics to wood. Different tool types are used for different processes and materials to meet a variety of machining needs. Below are five common types of machining tools that are used in a wide range of manufacturing and processing applications.view

EN

EN

ru

ru