CNC milling and CNC turning are two commonly used CNC machining methods, and they both utilize the CNC system to control the movement of the machine tool and achieve precise machining of the workpiece. However, they also have many differences, mainly in the following aspects:

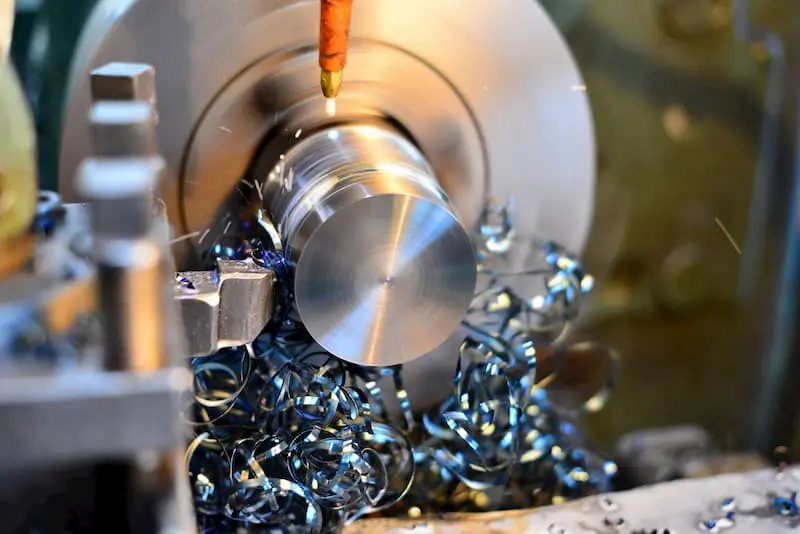

- Working principle: CNC milling is the use of rotating tools along the horizontal or vertical axis of the fixed workpiece cutting, mainly used for machining flat surfaces, grooves, gears, helical surfaces and other various surfaces of the workpiece. CNC turning is the use of fixed tools along the linear or curved trajectory of the rotating workpiece cutting, mainly used for processing shafts, disks, sets and other workpieces with rotary surface.

- Machining capacity: CNC milling can process a variety of complex surfaces and shapes, but can not process cylindrical or conical surfaces. CNC turning can process workpieces with rotational symmetry, but cannot process complex surfaces and shapes. CNC milling can also be drilling, tapping, knurling and other processing, while CNC turning needs to work with other equipment or processes.

- Cutting tool characteristics: CNC milling tools are multi-point tools, each time there are more than one tooth in contact with the workpiece, the cutting force is larger, the tool life is shorter. CNC turning tool is a single-point tool, each time there is only one tool tip in contact with the workpiece, the cutting force is smaller, the tool life is longer.

- Cutting mode: CNC milling uses intermittent cutting, the tool is in constant contact with the workpiece and disengagement, the cutting speed and feed rate is relatively high. CNC turning involves continuous cutting, the tool is always in contact with the workpiece, the cutting speed and feed rate is relatively low.

According to the above differences, we can choose the appropriate machining method according to the shape, size, material, precision, quantity and other factors of the workpiece. Generally speaking, CNC milling is suitable for processing complex non-rotationally symmetric workpieces, while CNC turning is suitable for processing simple rotationally symmetric workpieces. Of course, there are some workpieces that require both CNC milling and CNC turning, and then it is necessary to arrange and optimize the process to improve the processing efficiency and quality.

Milling before turning refers to roughing the workpiece with a CNC milling machine first, and then finishing the workpiece with a CNC lathe. The advantage of this method is that it can reduce the deformation and stress of the workpiece and improve the accuracy and surface quality of the workpiece. The disadvantage of this method is that it requires several times of clamping and centering, which increases the processing time and cost.

Turning before milling refers to roughing the workpiece with a CNC lathe first and then finishing the workpiece with a CNC milling machine. The advantage of this method is that it can reduce machining time and cost and improve machining efficiency. The disadvantage of this method is that it may lead to deformation and stress of the workpiece, reducing the precision and surface quality of the workpiece. According to the material, structure, size, precision and other requirements of the workpiece, you can choose the appropriate process method.

CNC milling and CNC turning are two different CNC machining methods, which have their own advantages and disadvantages and are suitable for different workpieces and occasions. In the actual machining process, it is necessary to select the appropriate machining method and process method according to the characteristics and requirements of the workpiece in order to achieve the best machining results. CNC machining is a comprehensive technology that requires continuous learning and practice to master its essence and skills.

Do you need high-quality CNC machining services? Whether your workpiece is a complex curved surface or a simple rotary body, Richconn can provide you with professional CNC turning services and CNC milling services to meet your various needs.Richconn has advanced equipment and technology to perform precision machining on workpieces in a wide range of materials and industries to ensure the dimensions, accuracy, surface quality, and performance of your workpieces. Richconn can also carry out customized design and machining according to your drawings or samples to meet your individual and diversified needs.Richconn's products are characterized by high precision, high quality, high efficiency and high cost performance, which have won the trust and praise of customers. If you would like to learn more about Richconn's CNC machining services, please feel free to visit our website or contact our online customer service.Richconn is looking forward to cooperating with you and providing you with the best quality customized CNC machining services.

Is NTPT Carbon Fiber A Gimmick or A Manifestation of Value?May 30, 2022When it comes to carbon fiber watches, we have to mention Audemars Piguet. Audemars Piguet is definitely the ancestor of carbon used in watches. In those days, bumblebees were hard to find. This is al...view

Is NTPT Carbon Fiber A Gimmick or A Manifestation of Value?May 30, 2022When it comes to carbon fiber watches, we have to mention Audemars Piguet. Audemars Piguet is definitely the ancestor of carbon used in watches. In those days, bumblebees were hard to find. This is al...view The Purpose and Importance of Metal Surface FinishApril 4, 2023Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an in...view

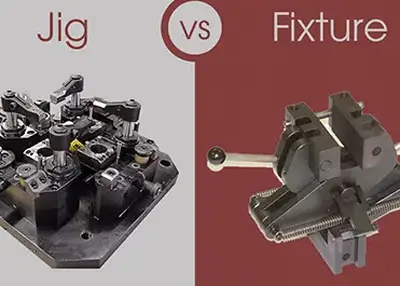

The Purpose and Importance of Metal Surface FinishApril 4, 2023Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an in...view Jig vs Fixture: Understanding the Differences and Applications of Two Common Workholding DevicesDecember 1, 2023Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.view

Jig vs Fixture: Understanding the Differences and Applications of Two Common Workholding DevicesDecember 1, 2023Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.view The Functional Advantages of Custom PVD Coating in Automotive DesignJanuary 5, 2024When it comes to automotive design, every detail matters. From the sleek lines of the exterior to the carefully crafted interior, each element plays a crucial role in creating a unique and memorable d...view

The Functional Advantages of Custom PVD Coating in Automotive DesignJanuary 5, 2024When it comes to automotive design, every detail matters. From the sleek lines of the exterior to the carefully crafted interior, each element plays a crucial role in creating a unique and memorable d...view In-depth Understanding of Five-axis CNC Service ProcessingOctober 24, 2022When it comes to cnc machining services, you will definitely think of 5-axis CNC machining. Choosing the right machining solution will lead to a successful production. CNC machining is a procedure use...view

In-depth Understanding of Five-axis CNC Service ProcessingOctober 24, 2022When it comes to cnc machining services, you will definitely think of 5-axis CNC machining. Choosing the right machining solution will lead to a successful production. CNC machining is a procedure use...view Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

EN

EN

ru

ru