Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing. There are many methods and techniques of metal joining, each with different characteristics and advantages. In this article, we will compare two common metal joining methods: welding and riveting. We will explain what they are, how they work, what are their pros and cons, and what are their common applications. We will also provide some tips on how to choose the right method for your project.

Welding and riveting are both fastening methods that use heat and pressure to join metal pieces or parts together. However, they have different mechanisms and principles of operation.

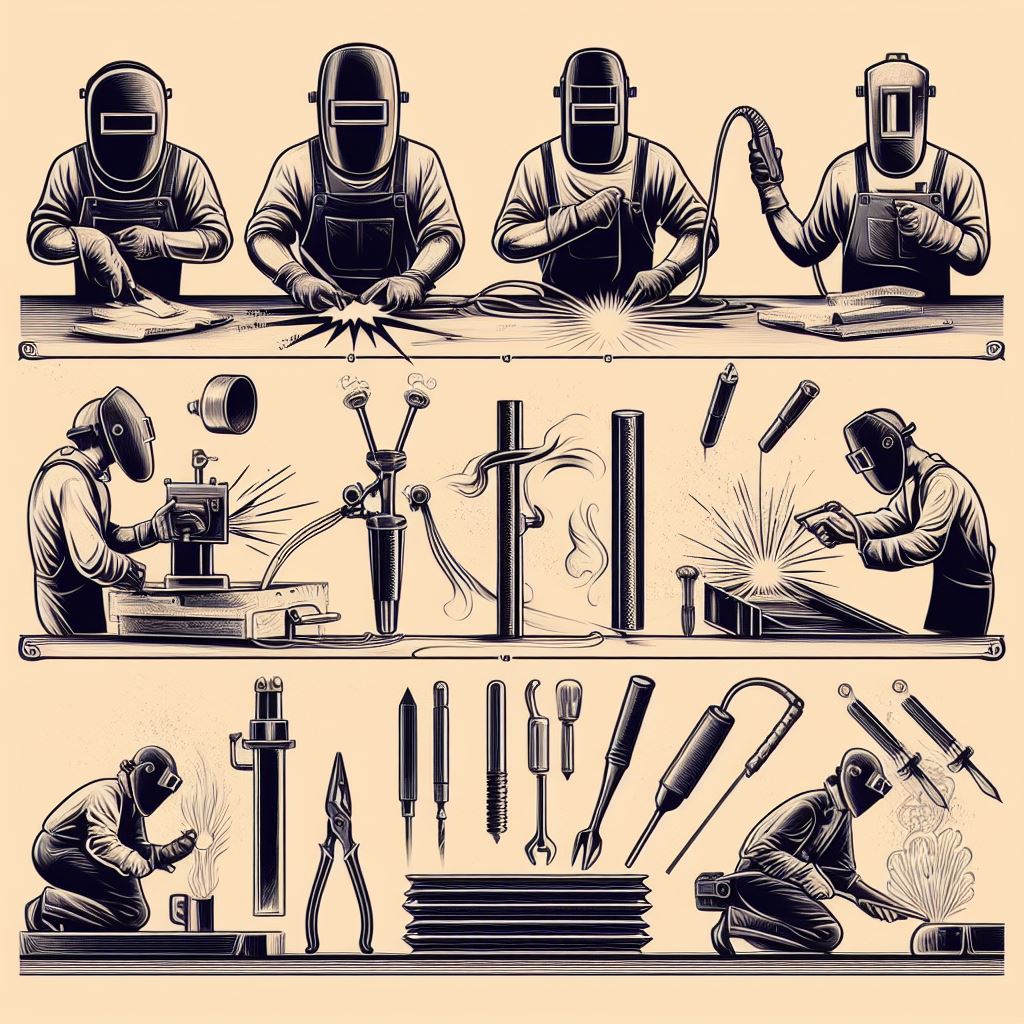

• Welding is a fastening method that creates a fused joint by melting the metal pieces or parts, or adding a filler material, to form a molten pool. The molten pool then solidifies and cools down, forming a strong and permanent bond between the metal pieces or parts. Welding can be done by using various sources of heat, such as electric arc, gas flame, laser, or ultrasound. Welding can also be done by using various types of filler materials, such as metal rods, wires, or powders.

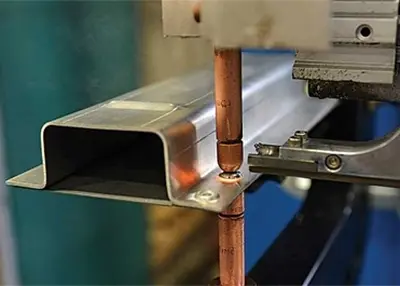

• Riveting is a fastening method that creates a mechanical joint by using a metal fastener, called a rivet, to join the metal pieces or parts together. A rivet is a metal pin that has a head at one end and a tail at the other end. The rivet is inserted into pre-drilled or punched holes in the metal pieces or parts, and then the tail is deformed or broken off, forming a second head, which holds the metal pieces or parts together. Riveting can be done by using various types of tools, such as hammers, rivet guns, or rivet machines.

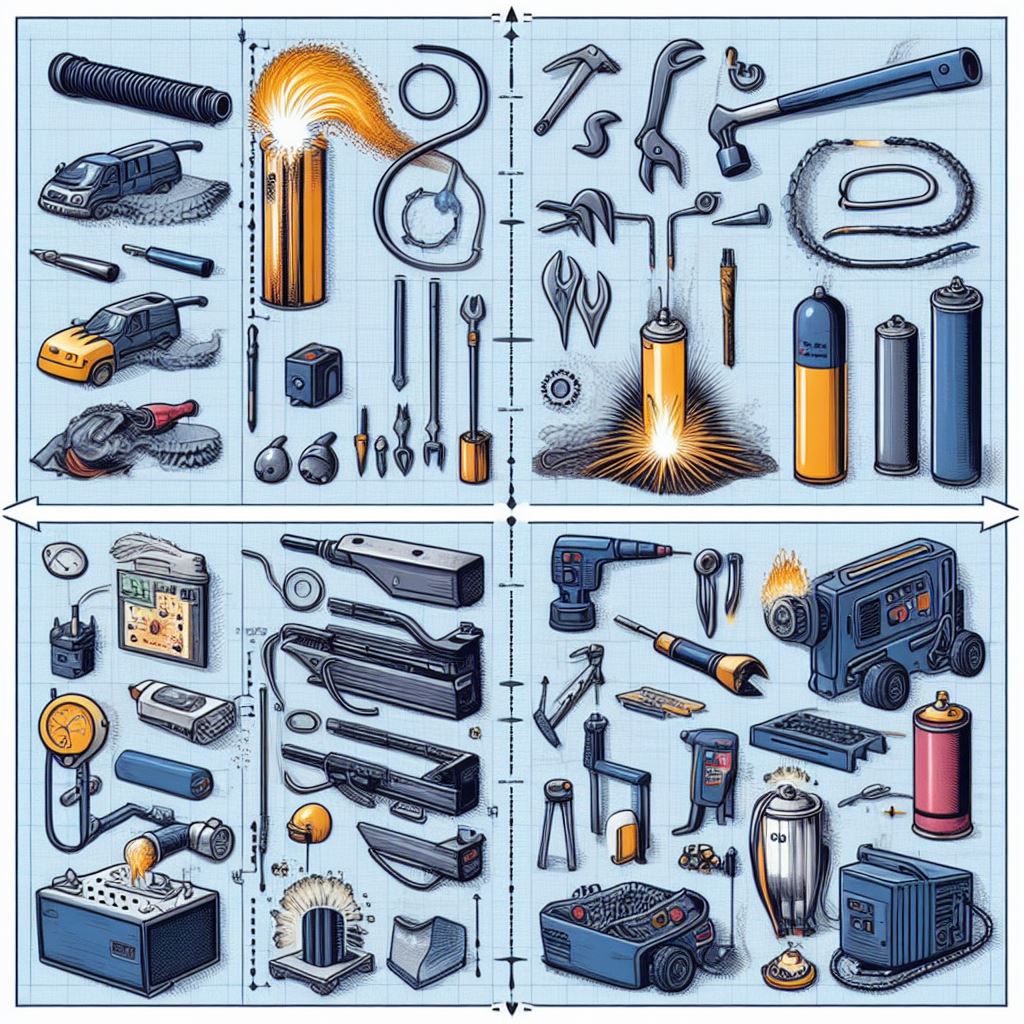

The following image shows a comparison chart of welding and riveting methods:

Both welding and riveting have their own advantages and disadvantages, depending on their properties and applications.

Welding can create a very strong and durable joint, as the metal pieces or parts are fused together as one. Welding can also create a smooth and seamless joint, as there are no gaps or protrusions between the metal pieces or parts. Welding can also reduce the weight and noise of the joint, as there are no additional fasteners or accessories required. Welding can also be used for a wide range of metals and shapes, as the heat and filler material can adapt to different materials and geometries.

Welding can be a complex and costly process, as it requires skilled labor, specialized equipment, and safety precautions. Welding can also cause distortion, deformation, or damage to the metal pieces or parts, as the heat and pressure can alter the metal structure and properties. Welding can also create a weak spot or crack in the joint, as the metal can become brittle or fragile due to the rapid cooling and solidification. Welding can also be affected by environmental factors, such as humidity, temperature, or corrosion, which can reduce the quality and longevity of the joint.

Riveting can be a simple and economical process, as it requires less skill, equipment, and preparation. Riveting can also create a reliable and consistent joint, as the rivet can provide a uniform and predictable clamping force. Riveting can also create a flexible and resilient joint, as the rivet can allow some movement and vibration between the metal pieces or parts. Riveting can also be used for a wide range of metals and thicknesses, as the rivet can accommodate different materials and dimensions.

Riveting can create a weaker and less durable joint, as the rivet can fail or loosen under stress or fatigue. Riveting can also create a rough and bulky joint, as the rivet can create gaps or protrusions between the metal pieces or parts. Riveting can also increase the weight and noise of the joint, as the rivet can add extra mass and friction. Riveting can also be limited by the availability and accessibility of the holes, as the rivet can only be inserted into pre-existing or pre-made holes.

The uses of welding and riveting depend on their properties and prices. Different methods are suitable for different fields and industries. Here are some examples of the uses of welding and riveting:

• Welding: Due to its high strength and durability, welding is mainly used for applications that require high performance and quality, such as construction, automotive, aerospace, and manufacturing. Some examples of welding products are bridges, buildings, cars, planes, ships, pipelines, etc.

• Riveting: Due to its simplicity and reliability, riveting is mainly used for applications that require low cost and ease of assembly, such as furniture, electrical, household, and hobby. Some examples of riveting products are cabinets, tables, chairs, lamps, toys, etc.

The welding and riveting are two different methods of metal joining, they have the following main differences and advantages:

• Welding is a fastening method that creates a fused joint by melting the metal pieces or parts, or adding a filler material, to form a molten pool. Riveting is a fastening method that creates a mechanical joint by using a metal fastener, called a rivet, to join the metal pieces or parts together.

• Welding can create a very strong and durable joint, as the metal pieces or parts are fused together as one. Riveting can create a reliable and consistent joint, as the rivet can provide a uniform and predictable clamping force.

• Welding can create a smooth and seamless joint, as there are no gaps or protrusions between the metal pieces or parts. Riveting can create a flexible and resilient joint, as the rivet can allow some movement and vibration between the metal pieces or parts.

• Welding can be a complex and costly process, as it requires skilled labor, specialized equipment, and safety precautions. Riveting can be a simple and economical process, as it requires less skill, equipment, and preparation.

• Welding can cause distortion, deformation, or damage to the metal pieces or parts, as the heat and pressure can alter the metal structure and properties. Riveting can create a weaker and less durable joint, as the rivet can fail or loosen under stress or fatigue.

• Welding can be used for a wide range of metals and shapes, as the heat and filler material can adapt to different materials and geometries. Riveting can be used for a wide range of metals and thicknesses, as the rivet can accommodate different materials and dimensions.

• Welding is mainly used for applications that require high performance and quality, such as construction, automotive, aerospace, and manufacturing. Riveting is mainly used for applications that require low cost and ease of assembly, such as furniture, electrical, household, and hobby.

If you are looking for a reliable and professional sheet metal fabrication service, I recommend you to check out Richconn, a leading custom precision machining factory that can provide you with high-quality welding and riveting service, as well as other metals and plastics. Richconn has rich experience and advanced equipment to meet your design requirements and application needs. You can visit their website or contact our online customer service for a free quote and consultation. I hope you can find the best solution for your metal products.

The Differences Between Riveting vs WeldingFebruary 18, 2024Let's explore the advantages, applications, and limitations of riveting and welding processes. Then, you can select the right method for assembling sheet metal parts.view

The Differences Between Riveting vs WeldingFebruary 18, 2024Let's explore the advantages, applications, and limitations of riveting and welding processes. Then, you can select the right method for assembling sheet metal parts.view CNC Powder Coating in Healthcare Equipment ApplicationsFebruary 29, 2024In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding...view

CNC Powder Coating in Healthcare Equipment ApplicationsFebruary 29, 2024In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding...view 4 Axis CNC Machining: The Definitive Guide 2023August 29, 2023CNC machining is a widely used manufacturing process that involves the use of computer-controlled machines to create precise and complex parts from various materials. CNC machines can operate on diffe...view

4 Axis CNC Machining: The Definitive Guide 2023August 29, 2023CNC machining is a widely used manufacturing process that involves the use of computer-controlled machines to create precise and complex parts from various materials. CNC machines can operate on diffe...view How Many Fasteners Are Needed in the Construction Machinery Sector?October 27, 2023Fasteners as commonly used parts, you should not be unfamiliar, today Richconn from the classification of fasteners, the identification and inspection of threads, bolts, screws and studs of the material requirements, heat treatment requirements and mechanical performance requirements, the types of steel bolts and the construction of the four aspects of the introduction.view

How Many Fasteners Are Needed in the Construction Machinery Sector?October 27, 2023Fasteners as commonly used parts, you should not be unfamiliar, today Richconn from the classification of fasteners, the identification and inspection of threads, bolts, screws and studs of the material requirements, heat treatment requirements and mechanical performance requirements, the types of steel bolts and the construction of the four aspects of the introduction.view Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view

Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view

What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view

EN

EN

ru

ru