3D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arises is: "How much do 3D prints cost?" Understanding the factors that contribute to 3D printing costs is essential for those considering this innovative technology.

Before delving into the costs, it's crucial to grasp the fundamentals of 3D printing. This technology involves the creation of three-dimensional objects from digital models, layer by layer. The printer builds up these layers using materials such as plastic filaments or resins, resulting in tangible, intricate objects. The appeal of 3D printing lies in its versatility, from rapid prototyping to creating custom products.

The first step in 3D printing is acquiring the necessary equipment. Prices for 3D printers vary widely based on factors like type, size, and quality. The average price of a 3D printer across the market is around $400. Some consumer-level printers would start as low as $200, while more advanced or industrial-grade models may exceed $1000. Keep in mind that the quality and capabilities of the printer often correlate with its cost.

Apart from the printer itself, the choice of printing materials significantly impacts the cost of 3D printing. Filaments, the most common materials, come in various types, qualities, and quantities. For example, a 1 kg spool of PLA filament, a popular choice for many applications, costs approximately $32.99. Resins, used in SLA and other resin-based printers, typically come in bottles and can be more expensive.

To answer the question of “how much do 3D prints cost”, several factors influence the overall 3D printing cost. One essential consideration is the complexity and size of your design. Another crucial factor is the choice of material. It's essential to select the right combinations for your 3D printing project to balance performance and cost.

Complexity and Size of the Design

The complexity and size of the 3D design you intend to print directly impact the 3D printing cost. Larger objects naturally require more material to complete, resulting in increased costs. Additionally, intricate designs with intricate details may take longer to print, leading to higher labor costs and more time spent on the printer.

Printing Resolution (Layer Height)

The printing resolution, often referred to as the layer height, determines how detailed the final 3D print will be. Smaller layer heights result in smoother surfaces and finer details, making them ideal for intricate and high-quality prints. However, lower layer heights demand more layers to build the object, which increases print time and material usage, leading to higher costs. On the other hand, larger layer heights reduce the time and material used but may sacrifice some level of detail.

Choice of Material

The type of material you select for your 3D printing project is a significant cost factor. Basic materials like PLA (Polylactic Acid) are generally more affordable, making them a popular choice for casual use and prototypes. However, specialty materials like ABS, PETG, or composite filaments, designed for specific properties such as high-temperature resistance or mechanical strength, often come at a higher price point.

Material Quantity and Quality

Apart from the type of material, the quantity and quality of the material required for your project contribute to the overall 3D printing cost. High-quality filaments and resins tend to be more expensive, but they can yield better print results. The amount of material needed depends on the size of the object and any potential support structures required during printing.

Post-Processing and Finishing

While the core 3D printing process is a significant cost factor, it's essential not to overlook the post-processing and finishing steps. Some prints may require additional steps such as sanding, painting, or assembling multiple printed parts. These finishing touches can add to the overall cost to 3D print, both in terms of time and any additional materials needed.

The choice between investing in a personal 3D printer and utilizing professional online 3D printing services is a significant decision for some people. Both options have their advantages and considerations.

Pros

Cost-Efficiency: For individuals who plan to undertake numerous 3D printing projects, purchasing a 3D printer would be cost-effective in the long run. The initial investment is substantial, but over time, the cost per print reduces significantly.

Convenience and Control: Owning a 3D printer gives you full control over the printing process. You can experiment with various materials, resolutions, and designs without the limitations imposed by external services.

Cons

Initial Investment: The upfront cost of a good-quality 3D printer can be a barrier for some. Moreover, cheaper printers might have limitations in terms of print quality and durability.

Maintenance and Learning Curve: Maintaining and calibrating a 3D printer requires time and effort. There's a learning curve involved, and you might face challenges along the way, especially if you're new to 3D printing.

Limited Materials and Expertise: DIY printers might not support the full range of materials and finishes that professional services offer. Achieving the same level of quality and diversity might be challenging.

Pros

Quality and Expertise: Online 3D printing services typically use high-quality equipment, ensuring superior print quality and precision. Their experience and expertise can result in professionally finished products.

Material Variety: Professional services often offer a wide range of materials, including specialty options like flexible filaments or industrial-grade resins. This allows you to choose the perfect material for your specific project.

Convenience: Using an online service eliminates the need for printer maintenance, calibration, and troubleshooting. You simply upload your design and receive a finished product, saving you time and effort.

Cons

Cost per Print: While the convenience is undeniable, using a professional 3D printing service can be costlier per print compared to owning a 3D printer.

Lead Times: Depending on the service's workload, the lead time for receiving your printed object can vary. If you need a quick turnaround, make sure to ensure the lead times.

When selecting 3D printing service providers, several critical factors come into play. The top 6 factors are as follows:

The first step is assessing the range of 3D printing technologies and materials available. Richconn stands out by offering a comprehensive selection of methods, such as FDM, SLA, SLS, etc. This ensures that you can choose the technology that best suits your project's requirements.

The ability to select from a diverse array of materials is essential to match your project's unique needs. Richconn offers engineering-grade materials. This material variety ensures that you can find the right material that aligns with your application's demands.

Consistent high quality is crucial in 3D printing. Richconn has a strict quality management system in place, conducting thorough inspections to eliminate defects or errors. This commitment to quality guarantees that the 3D printed parts you receive meet your specifications and expectations.

Richconn's team brings over a decade of experience in OEM CNC machining and 3D printing. Their expertise spans diverse industries, from automotive to medical, ensuring that they understand the specific challenges and requirements of your project.

Timely delivery is often critical in product development and manufacturing. Richconn-CNC's digital platform streamlines the ordering process, coupled with their experienced staff, ensuring a fast production turnaround for your prototypes or parts.

Compare the pricing structures and cost estimates of different 3D printing service providers. Consider factors such as material costs, machine setup fees, and any additional services you may need (e.g., post-processing or design assistance). Richconn offers transparency in pricing and ensure that it fits within your budget.

Try the best 3D printing services ↓↓↓

Whether embarking on a DIY journey with a personal printer or leveraging the expertise of professional 3D printing services like Richconn, the trade-offs between 3D printing costs, convenience, and quality must be carefully considered. As the 3D printing landscape continues to evolve, armed with insights into these cost dynamics, individuals and enterprises can make informed decisions that harmonize creativity, precision, and budgetary considerations in their pursuit of transformative fabrication.

Unveiling the World of Helical Machined Springs: A Comprehensive ExplorationNovember 15, 2023Embarking on a journey through the intricate world of helical machined springs is more than just an exploration of engineering marvels – it's a pathway to unlocking innovation, efficiency, and reliability in diverse industries. In this article, I'll guide you through the essential aspects of helical machined springs, from their fundamental workings to practical applications and market trends.view

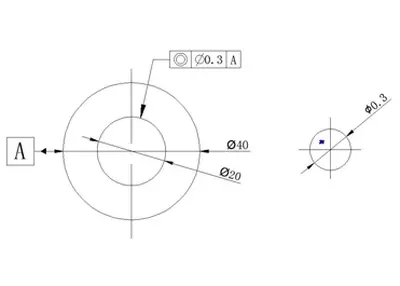

Unveiling the World of Helical Machined Springs: A Comprehensive ExplorationNovember 15, 2023Embarking on a journey through the intricate world of helical machined springs is more than just an exploration of engineering marvels – it's a pathway to unlocking innovation, efficiency, and reliability in diverse industries. In this article, I'll guide you through the essential aspects of helical machined springs, from their fundamental workings to practical applications and market trends.view Positioning control - concentricity/coaxialityNovember 17, 2023When manufacturing cylindrical CNC milled parts, concentricity is the unit of measure of part accuracy. Concentricity, is the degree to which the inner diameter of the insert is offset from the center of the entire circle.view

Positioning control - concentricity/coaxialityNovember 17, 2023When manufacturing cylindrical CNC milled parts, concentricity is the unit of measure of part accuracy. Concentricity, is the degree to which the inner diameter of the insert is offset from the center of the entire circle.view What Is CNC Metal Processing | A Comprehensive GuideJune 4, 2024What is CNC metal processing? What should we pay attention to when choosing a reliable partner for the metal processing project? Here come the answers!view

What Is CNC Metal Processing | A Comprehensive GuideJune 4, 2024What is CNC metal processing? What should we pay attention to when choosing a reliable partner for the metal processing project? Here come the answers!view Climb vs Conventional Milling: What Are the Differences?March 20, 2024Understanding climb vs conventional milling clearly is one way to help you choose the right milling process. Here is a comprehensive guide to their differences.view

Climb vs Conventional Milling: What Are the Differences?March 20, 2024Understanding climb vs conventional milling clearly is one way to help you choose the right milling process. Here is a comprehensive guide to their differences.view What are the commonly used surface finishing?September 27, 2023Surface finishing is to clean, sweep, deburr, de-grease, de-oxidize, etc., the surface of the workpiece, which is used to meet the corrosion resistance, abrasion resistance, decorative or other special functional requirements of the product.view

What are the commonly used surface finishing?September 27, 2023Surface finishing is to clean, sweep, deburr, de-grease, de-oxidize, etc., the surface of the workpiece, which is used to meet the corrosion resistance, abrasion resistance, decorative or other special functional requirements of the product.view How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view

How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view

EN

EN

ru

ru