Even if you don't have in-depth knowledge of manufacturing and machining, you may have heard of a metal lathe. These machines are widely used in machine shops, second only to milling machines in popularity. A CNC lathe machinist may use a lathe CNC machine for sale. If you are a business owner, plant manager, or supervisor responsible for purchasing a used CNC lathe machine for sale, it is essential to understand them. We will start with the basics to help you understand these versatile and essential machines. Then, we will move on to some helpful buying tips to ensure that you are prepared and well-informed about your purchase.

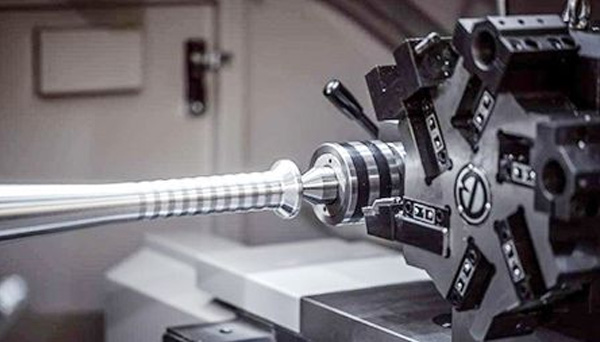

Lathes are machine tools that rotate a workpiece to carry out various operations and shape it into the desired cylindrical form. They were first utilized in Ancient Egypt around 1300 BC, and then the French began using them around 1550 CE to create wooden works. During the Industrial Revolution, the modern lathe was developed, which is still utilized in numerous manufacturing industries today. Historically, traditional lathes consistently comprised of a 2-axis and a flatbed, a characteristic that can still be observed in contemporary CNC lathe beds, such as mini CNC lathe, small CNC lathe, and desktop CNC lathe. The more contemporary, Computer Numerical Control (CNC) lathes operate with the assistance of computers. It functions similarly to a regular lathe, except that the cutting process is overseen by computer programming. This leads to a highly precise finished work that is more accurate and efficient than a manual lathe.

Tailstock: Most two-axis lathes are equipped with a spindle, chuck, lathe bed, and carriage, but a movable tailstock might not be a standard feature. If you expect to turn long, small-diameter shafts, it's essential to support the workpiece at the end opposite the chuck and headstock. Without its support, you might get chatter marks or taper, making the shaft unusable. It also enables drilling and reaming holes in the center of the part.

Heavy-duty cast-iron bed and base: A heavy lathe machine allows for deeper cuts, greater rigidity, and less vibration. For the longevity and highest precision of the machine tool, always choose a lathe with a heavy-duty cast-iron base instead of one made of welded steel.

Removable ways: Some lathes have a portion of the ways below the chuck that can be removed, creating a "gap". This feature allows for turning larger diameters since it increases the clearance for a larger swing diameter. It's something to consider.

Large diameter borehole through the machine: When the workpiece needs to extend through the back of the chuck, the spindle through-hole diameter determines the maximum part diameter. Some lathes are designed with "big-bore" options, which might be necessary if you work on long shafts with larger diameters.

Steady rest: A steady rest is a ring with adjustable jaws attached to the lathe's ways to support the workpiece. Typically, the frame of the steady rest is split, with the top half of the ring being hinged and closing around the shaft for stability.

High-quality products: Particularly, the CNC and lathe machine produce final products with exceptional quality.

High speed: The machining process in the lathe, especially in automatic and CNC lathe machines, can be carried out at a very high speed.

Time savings: Due to its high speed and accuracy, the lathe machine saves a significant amount of time, leading to increased production. - Cost savings: The lathe machine aids in reducing the cost of machining as it requires fewer operators for the process.

CNC lathes come in different types, such as CNC wood lathe, CNC mini lathe, each with its unique features and applications. Slant bed lathes are ideal for medium-sized workpieces, while flatbed lathes are used for heavy-duty turning. Vertical lathes, on the other hand, are beneficial for handling large piecework. Understanding these types can help optimize the manufacturing process. DIY CNC lathe is also a popular choice for those who enjoy hands-on projects.

Slant Bed Lathes

Slant beds are ideally suited for medium-sized workpieces, making them highly applicable in the aerospace and optics industries. Their multi-station turrets provide the capability for the concurrent use of multiple tools, enhancing efficiency and productivity. Additionally, their speed enables a significant reduction in production cycles, leading to a faster turnaround time. Furthermore, their compatibility with automation systems facilitates a reduction in the reliance on manual labor, allowing for a more streamlined and efficient manufacturing process.

Flatbed lathes

Flatbeds are employed in the manufacturing process, particularly in heavy-duty turning that demands considerable strength and power. The higher stability of the beds translates to enhanced precision and accuracy, making them an excellent choice for fabricating intricate geometrical workpieces and handling larger workpieces. However, they present more limitations in terms of tool-changing, as changing from boring to knurling tools, for instance, will consume time.

Vertical Lathes

Vertical lathes are beneficial for heavy-duty applications as they facilitate the positioning of workpieces. By leveraging gravity, the vertical lathe enables the secure holding of pieces in place, minimizing the dependency on clamps, and enhancing efficiency for large workpieces ranging from 1 to 20 meters. Similar to slant bed lathes, CNC vertical lathe also permit multi-tooling, which effectively boosts productivity.

With the advancement of technology, CNC lathes, especially small CNC lathes, have become an appealing alternative to more traditional production lathes that have been historically utilized, such as the multispindle. They offer numerous advantages. CNC lathe operators find these lathes easy to set up and operate, and they provide a desirable combination of serious repeatability and premier production accuracy.

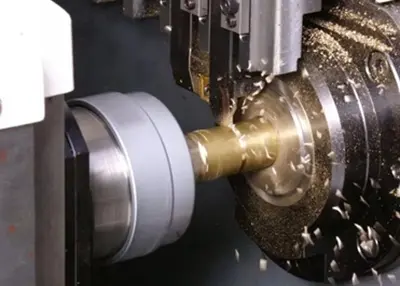

Many CNC lathes are designed to utilize the most contemporary applications of carbide tooling processes. Specific parts can be customized, and then the actual tool paths of the machine are programmed using processes like CAM or CAD. Programmers can even design tool and part paths manually if they prefer. Regardless of the final coded computer file, it is uploaded into the lathe, allowing the machine to commence automatic production on the parts it is programmed to create according to the design intent.

Finished production items created using CNC lathing include baseball bats, camshafts, cue sticks, gun barrels, musical instruments, and crankshafts. They are commonly employed in the manufacturing of the legs of dining room chairs where you sit, the legs of the kitchen table where you eat, and even some of the bowls from which you eat. You likely use products made by CNC lathes in your daily life. In addition, there are also many used CNC lathes and CNC lathes for sale on the market.

In today's era, multi-axis CNC machining centers can potentially blur the boundaries between CNC lathe metal and CNC mills and lathes. However, for most practical purposes, they are two distinct and separate machines. When you step into most machine shops or other manufacturing facilities, you will likely observe lathes and milling machines on their production floors.

While both machines adhere to the same fundamental machining principle of removing material from a block, how they shape the part distinguishes them. The primary distinction between a lathe and a milling machine lies in the relationship between the workpiece and the cutting tool. On a lathe, the workpiece rotates around its axis, while the cutting tool remains stationary. This process is referred to as "turning," resulting in a cylindrical-shaped part. Operations carried out on a lathe include turning, boring, ID/OD grooving, threading, drilling, and parting.

Conversely, on a milling machine, the cutting tool rotates around its axis while the workpiece remains fixed in place. This configuration enables the tool to approach the workpiece from multiple directions, facilitating the creation of complex parts. The milling machine boasts the advantage of versatility, as its tooling options are nearly limitless. Despite the limitations in the application of lathe machines, they excel in the production of cylindrical parts. If your operations require the creation of round parts, the lathe will outshine the milling machine, enhancing productivity and quality.

CNC machines are very powerful, which can add speed and versatility to any machine shop or home workshop. Richonn's CNC lathes meet almost all the criteria of speed lathes and precision lathes!

Richonn stands out with its fast ordering process, precision digital CNC machining service platform, state-of-the-art machinery, and strict quality management system. By partnering with Richonn, you can expect to receive high-quality CNC machining parts and exceptional service.

Richonn has plenty of advantages:

It provides a fast ordering process with a precision digital CNC machining service platform and owns CNC machining shops and state-of-the-art machinery to accelerate the production of CNC machining or CNC machining parts.

It also strictly implements a quality management system to ensure the consistent quality of products and CNC manufacturing services and full inspections to ensure that you receive high-quality CNC machining parts without defects.

A variety of CNC plastic and heavy CNC metal lathes are in stock, suitable for various applications and industries, such as ABS, polycarbonate, nylon, aluminum, CNC stainless steel, platinum, and copper.

It is a professional online CNC machining manufacturer, and you can contact them at any time by phone or email.

In conclusion, CNC lathes offer numerous benefits of CNC lathe for sale, including high-quality products, high speed, time savings, and cost savings. When it comes to purchasing a CNC lathe, it is essential to choose a reliable manufacturer like Richonn.

Don't hesitate to contact Richonn and experience the excellence they have to offer. Let's work together with Richonn to bring your machining projects to life and achieve outstanding results.

With Richonn, you can trust that you are choosing a partner who is dedicated to providing the best in CNC lathe technology and customer satisfaction. Join us in the world of precision machining and unlock the potential of your projects!

Four Requirements for Medical Component ProcessingMay 22, 2023For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processe...view

Four Requirements for Medical Component ProcessingMay 22, 2023For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processe...view Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view

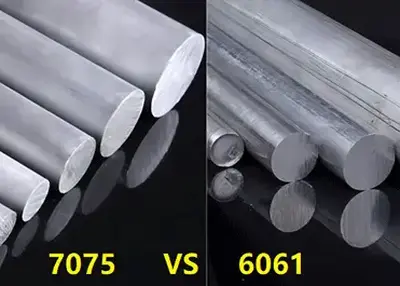

Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view Comparison of 7075 Aluminum Alloy vs 6061 Aluminum AlloyNovember 27, 2023Aluminum alloy is a widely used metal material with the advantages of light weight, high strength, corrosion resistance and recyclability. There are many types of aluminum alloys, and different alloying elements and heat treatment processes affect the properties and uses of aluminum alloys.view

Comparison of 7075 Aluminum Alloy vs 6061 Aluminum AlloyNovember 27, 2023Aluminum alloy is a widely used metal material with the advantages of light weight, high strength, corrosion resistance and recyclability. There are many types of aluminum alloys, and different alloying elements and heat treatment processes affect the properties and uses of aluminum alloys.view An Ultimate Guide to Medical Device ManufacturingMarch 13, 2024Nowadays, manufacturing medical devices is becoming more and more important. This article will let you know more about medical device manufacturing.view

An Ultimate Guide to Medical Device ManufacturingMarch 13, 2024Nowadays, manufacturing medical devices is becoming more and more important. This article will let you know more about medical device manufacturing.view How to Get a Clear Picture of Quenching, Normalizing, Tempering and Other Material Heat Treatment Issues?October 24, 2023Heat treatment of steel consists of normalizing, annealing, tempering and quenching. Among them, annealing and normalizing are mainly used for preparatory heat treatment, and are only used as final heat treatment when the performance of the workpiece is not required. The purpose of quenching is to obtain martensitic organization and improve the performance of steel.view

How to Get a Clear Picture of Quenching, Normalizing, Tempering and Other Material Heat Treatment Issues?October 24, 2023Heat treatment of steel consists of normalizing, annealing, tempering and quenching. Among them, annealing and normalizing are mainly used for preparatory heat treatment, and are only used as final heat treatment when the performance of the workpiece is not required. The purpose of quenching is to obtain martensitic organization and improve the performance of steel.view What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

EN

EN

ru

ru