As technology continues to evolve, so does manufacturing, and Computer Numerical Control (CNC) machines are one of the highlights of this field.Known for their high precision, efficiency, and versatility, CNC machines have become a mainstay of modern manufacturing. In this article, we will take an in-depth look at the definition, working principles, types, application areas and future trends of CNC machines for a better understanding of this exciting manufacturing technology.

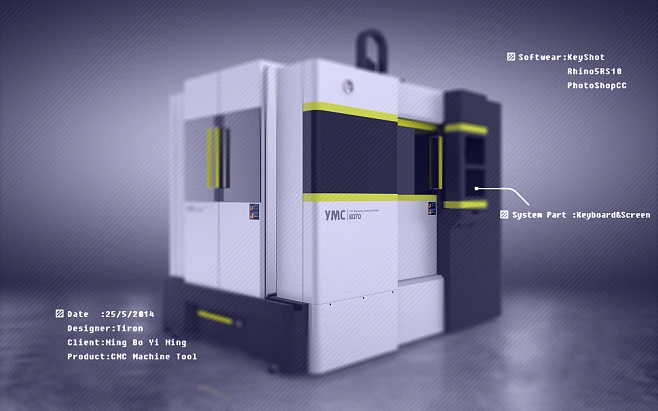

CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program. Compared with traditional manual operations, CNC machines are characterized by high accuracy and repeatability, and can process a wide variety of materials, including metals, plastics, wood, etc. The core idea of a CNC machine is to convert a three-dimensional design model into a specific cutting path, and computer control of the machine movement to achieve precise machining.

The working principle of a CNC machine involves computer programming, mechanical structure and electronic control systems. First, a designer uses computer-aided design (CAD) software to create a three-dimensional model, then computer-aided manufacturing (CAM) software is used to translate the design into instructions that the machine can understand. These instructions include information such as tool paths, cutting speeds, and feed rates.

Next, these instructions are transmitted to the CNC controller, which is the brain of the CNC machine. The controller interprets these instructions and translates them into currents, voltages, and pulses that control the movement of each axis.CNC machines typically have multiple axes, including X, Y, and Z, which control the horizontal, vertical, and depth movements of the machine, respectively.

During operation, a cutting tool (such as a drill, milling cutter, or laser head) moves and rotates precisely according to the controller's commands to perform operations such as cutting, engraving, or punching holes in the workpiece. The controller constantly detects the position of the tool and makes fine adjustments as needed to ensure precision and quality of the machining.

The versatility of CNC machines is what makes them so powerful, with different types of CNC machines specializing in a variety of different machining and manufacturing needs. In this section, we'll take an in-depth look at a few common types of CNC machines, including how they work, their areas of applicability, and some notable real-world application examples.

A CNC milling machine is a type of CNC machine widely used for machining metals, plastics, and other hard materials. It works by removing parts of the material by rotating a tool to form the desired shape. Here are some of the key features and application areas of CNC milling machines:

Multi-axis control: CNC milling machines usually have three, four or five-axis control, allowing them to cut in multiple directions for complex parts machining.

Areas of application: CNC milling machines are widely used in aerospace, automotive manufacturing, mold and die making, machining and electronics manufacturing. For example, in the aerospace sector, CNC milling machines are used to manufacture airplane wings and engine parts.

Case in point: An automotive manufacturing company uses CNC milling machines to machine aluminum parts for car engines, ensuring high precision and quality manufacturing. This helps improve engine performance and fuel efficiency.

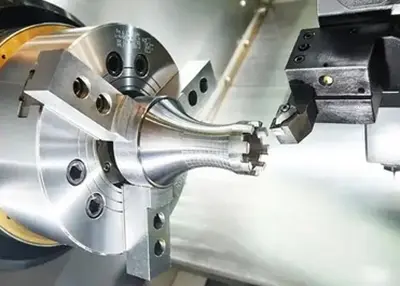

CNC Lathes are CNC machines specialized in rotating workpieces for machining. They achieve machining by rotating the workpiece and cutting it with a tool. Some of the features and application areas of CNC lathes are listed below:

Rotary machining: CNC lathes cut the workpiece by rotating the workpiece and making the tool cut on the workpiece, which is usually used for manufacturing bearings, threads and other rotating parts.

Application areas: CNC lathes are widely used in automobile manufacturing, aerospace, medical equipment manufacturing and precision instrument manufacturing. For example, in the medical device field, CNC lathes are used to manufacture metal parts for artificial joints.

Case in point: an aerospace company uses CNC lathes to machine bearings in aircraft engines to ensure their accuracy and reliability to improve the performance and safety of the aircraft.

Laser cutting machines use a high-energy laser beam to cut a variety of materials, including metals, plastics, glass and wood. The following are some of the features and application areas of laser cutting machines:

High Precision Cutting: Laser cutting machine can realize very precise cutting without touching the surface of the workpiece, so there is no wear and tear as in mechanical cutting.

Areas of application: Laser cutting machines are widely used in metal processing, automobile manufacturing, electronics manufacturing and construction. For example, in the construction field, laser cutters can be used to cut complex shaped metal components for building structures.

Case in point: an electronics manufacturing company uses laser cutters to cut precision parts for circuit boards, ensuring high performance and reliability of electronic equipment.

CNC Engraving Machines are used to engrave and cut on surfaces such as wood, stone, glass and metal. Here are some of the features and application areas of CNC Engraving Machine:

Multi-material processing: CNC Engraving Machines can handle many different types of materials and therefore have a wide range of applications in the field of art and sculpture.

Application areas: CNC engraving machines are widely used in the fields of artwork production, ornament manufacturing, architectural decoration and sculpture production. For example, in the field of architectural decoration, CNC engraving machines can be used to make complex columns and reliefs.

Case in point: a sculptor uses a CNC engraving machine to produce large-scale sculptures, enabling him to realize high-precision engraving in a short period of time.

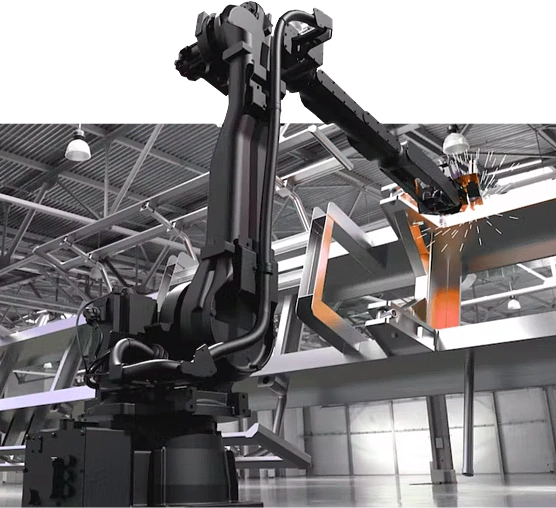

CNC Welding Robot is used to automate the welding process and improve the quality and productivity of welding. Following are some of the features and application areas of CNC Welding Robot:

High Precision Welding: CNC Welding Robot can realize high precision welding and reduce welding defects and waste.

Application areas: CNC welding robots are widely used in the fields of automobile manufacturing, ship construction, building structures and pipe manufacturing. For example, in automobile manufacturing, CNC welding robots are used to weld car chassis and bodies.

Case in point: a pipe manufacturing company uses CNC welding robots to weld long lengths of pipe, increasing productivity and reducing labor costs.

The versatility and applicability of CNC machines make them an important tool in modern manufacturing. Whether in aerospace, automotive manufacturing, medical devices or the arts, CNC machines play a key role in driving innovation and growth in manufacturing. As technology continues to advance, we can expect CNC machines to continue to play an even greater role in future applications, bringing us even more precision and efficient machining solutions.

Richconn has many years of experience in CNC machining services to provide superior manufacturing solutions to their customers. Their team of professionals are well versed in CNC machining technology, ensuring that every project is completed efficiently and accurately. Whether it's in aerospace, automotive manufacturing, medical devices, or any other field, Richconn has always been known for exceptional quality and reliability. Their commitment and work ethic certainly make them a partner of choice. If you are looking for a reliable CNC machining service provider, Richconn is highly recommended.

CNC (Computer Numerical Control) machines are a revolutionary manufacturing technology with a wide range of applications covering almost all industrial and creative fields. In this section, we will explore in more detail the specific applications of CNC machines in various fields and how they are driving modern manufacturing and innovation.

The aerospace industry has always been one of the most important areas for CNC machine applications. CNC machines play a key role in this highly precise and safety demanding field. Following are the major applications of CNC machines in the aerospace industry:

Aircraft parts manufacturing: CNC machines are used to manufacture a variety of key components for aircraft, including engine parts, wings, propellers, cabin structures, and more. They ensure high precision and quality of parts while increasing production efficiency.

Model and Prototype Manufacturing: When designing a new aircraft or upgrading an existing one, CNC machines are used to manufacture aircraft models and prototypes in order to test the performance and flight characteristics of the new design.

Spacecraft Component Manufacturing: Not just for airplanes, CNC machines are used to manufacture a wide range of components for spacecraft, including satellites, rocket motors and space probes.

Repair and Restoration: CNC machines also play a key role in the aviation maintenance sector, where they are used to manufacture and repair aircraft components to ensure their safety and reliability.

Automotive manufacturing is another major application area for CNC machines. Modern automobiles not only require high performance and safety, but also sophisticated manufacturing processes. The following are the applications of CNC machines in automobile manufacturing:

Engine Component Manufacturing: The automobile engine is the heart of the vehicle and its accuracy and performance is critical. CNC machines are used to machine components such as engine blocks, crankshafts, pistons and valves.

Chassis Component Manufacturing: Chassis components such as suspension, braking and steering systems also require a high degree of precision manufacturing to ensure vehicle handling and safety.

Body Component Manufacturing: CNC machines are used to manufacture body components including body panels, doors, hoods and trunks. The accuracy of these components is critical to the appearance and performance of the vehicle.

Automotive Electronics Manufacturing: Modern automobiles contain a large number of electronic components such as Electronic Control Units (ECUs), navigation systems, and safety systems CNC machines are used to manufacture these complex electronic parts.

The field of medical device manufacturing is also one of the major application areas for CNC machines. In the medical field, precision and reliability are absolutely critical factors, making the use of CNC machines crucial.

Prosthetics manufacturing: CNC machines are used to manufacture highly personalized prosthetics and orthotics, customized to the patient's body shape and needs.

Artificial Joint Manufacturing: CNC machines are used to manufacture artificial joints, such as artificial hip and knee joints. These artificial joints must be precisely adapted to the patient's body in order to restore their normal joint function.

Dental Instrument Manufacturing: CNC machines are used to manufacture dental instruments, such as crowns and bridges, as well as dental chairs, which require extreme precision.

Medical Device Component Manufacturing: CNC machines are used to manufacture components for a variety of medical devices, including X-ray machines, MRI machines, and surgical instruments.

Electronics manufacturing is one of the most important areas of application for CNC machines, as modern electronic devices require a high degree of precision and complexity.

Circuit board manufacturing: CNC machines are used to manufacture electronic circuit boards, which include tiny electronic components such as soldering and assembly of electronic components.

Enclosure Manufacturing: Electronic devices often require enclosures to protect the internal circuits and components, and CNC machines are used to manufacture precision enclosures and housings.

Connector Manufacturing: Connectors are one of the key components of electronic devices and CNC machines are used to manufacture various types of connectors to ensure the reliability of their connections.

Precision Instrument Manufacturing: CNC machines are used to manufacture various precision instruments such as microscopes, spectrometers and precision measuring devices.

Mold manufacturing is one of the key areas of manufacturing which provides the necessary tools and equipment for other industries.CNC machines play a key role in mold manufacturing.

Plastic Injection Mold Manufacturing: CNC machines are used to manufacture plastic injection molds, which are used to produce a variety of plastic products such as bottles, lids and containers.

Die Casting Mold Manufacturing: Die casting molds are used to make metal parts such as automotive components and household appliance parts CNC machines can make highly precise die casting molds.

Stamping Die Manufacturing: Stamping dies are used to punch and shear sheet metal into desired shapes, such as automotive body parts and appliance housings.

Artists and sculptors are also finding great potential in CNC machines for creating intricate works of art and sculpture. The application of CNC machines in this field not only promotes innovation in art, but also improves the efficiency of artwork production.

Complex carving: CNC machines can perform highly precise carving work to create intricate sculptures that may take several times the time and effort required in traditional carving methods.

Artwork Production: Artists can use CNC machines to produce artwork such as sculptures, installations and decorative objects to realize their creative vision.

Sculpture Reproduction: CNC machines can also be used to reproduce sculptures, maintaining the accuracy of the original work while producing multiple copies for sale or exhibition.

In short, CNC machines have come to play an irreplaceable role in a variety of fields, driving the development of modern manufacturing and creative industries. Their high precision, efficiency and versatility have made them key tools in a variety of industries, providing strong support for innovation and the manufacture of high-quality products. In the future, as technology continues to advance, CNC machines will continue to play a key role in bringing more opportunities and challenges to various fields.

Since its introduction, 3D printing technology has had a far-reaching impact in a variety of industries. At the same time, numerically controlled machines (CNC machines), a key technology in traditional manufacturing, have been evolving and developing. However, some may be confused as to whether 3D printers can be considered a form of CNC machine tools.

The Basics of 3D Printing Technology

3D printing technology, also known as additive manufacturing, is a manufacturing method that transforms digital design files into solid objects. Its basic principle is the gradual construction of three-dimensional objects by stacking or spraying materials layer by layer. Below are the main features and principles of 3D printing technology:

Layer-by-layer stacking: 3D printers use layer-by-layer stacking to build three-dimensional objects by adding material layer by layer from the bottom to the top. This layer-by-layer building process makes it possible to create highly complex geometric shapes.

Material Versatility: 3D printing can be done with a variety of materials, including plastics, metals, ceramics, biomaterials, and more. Different printing materials are suitable for different applications.

Digital Design Files: Key to 3D printing are digital design files, which can be created by computer-aided design (CAD) software and then converted into standard 3D printing formats such as STL files.

Wide range of applications: 3D printing technology has been widely used in a variety of fields such as manufacturing, medical, aerospace, automotive manufacturing, art, etc. for prototyping, customized manufacturing, and rapid manufacturing.

Differences and similarities between 3D printers and CNC machines

While 3D printing technology and CNC machines are both key technologies for modern manufacturing, there are some key differences and similarities between them.

Difference:

Principles of manufacturing: 3D printing is an additive manufacturing technology that builds objects by stacking or spraying materials layer by layer, while CNC machines are a manufacturing technology that removes materials and creates objects through processes such as cutting or milling.

Material selection: 3D printing can use a variety of materials, including plastics, metals, and ceramics, while CNC machines are typically used for materials such as metals, plastics, and wood.

Manufacturing speed: 3D printing is usually slower than CNC machines because it requires stacking materials layer by layer; whereas CNC machines can remove large amounts of material in a short period of time.

Similarities:

Digital manufacturing: both 3D printing and CNC machines rely on digital design files that are controlled by computer programs to control the manufacturing process.

Accuracy: Both 3D printing and CNC machines allow for highly accurate manufacturing for applications that require precision parts.

Custom Manufacturing: Both 3D printing and CNC machine tools have the ability to customize manufacturing, allowing personalized products and parts to be made according to specific needs.

3D printing technology and CNC machine tools have unique advantages and applicability in different application areas.

The main application areas of 3D printing technology:

Medical field: 3D printing is used to manufacture prosthetic limbs, artificial joints, dental instruments and medical models.

Aerospace: 3D printing can be used to manufacture lightweight components, engine parts and prototypes.

Automotive Manufacturing: Automakers use 3D printing to create automotive parts, customized accessories, and prototypes.

Art and design: Artists and designers use 3D printing to create complex artwork and design models.

Metalworking: CNC machines are widely used in metal cutting, milling, drilling and grinding in machining areas such as automotive manufacturing and aerospace.

Woodworking: CNC machines are used in woodworking to make furniture and building components.

Mold Making: CNC machines are indispensable in the field of manufacturing molds, plastic injection molds and die casting molds.

Medical Equipment: CNC machine tools are used to manufacture medical equipment parts, such as surgical instruments and medical instruments.

CNC machine tools are a key component of modern manufacturing, and they drive manufacturing through automation, high precision and efficient machining processes. They have a wide range of applications in various fields, from aerospace to medical device manufacturing. As technology continues to advance, CNC machine tools will continue to play an important role in driving manufacturing towards smarter, more sustainable solutions.

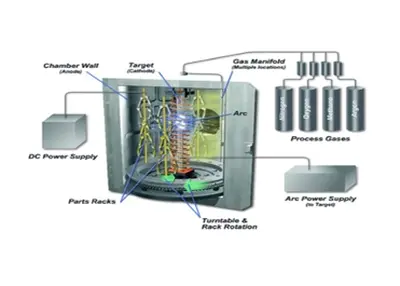

The Role of Custom PVD Coating in Industrial ApplicationsJanuary 5, 2024In today's fast-paced industrial world, companies are constantly seeking ways to enhance the performance and durability of their products. One effective method that has gained popularity is custom...view

The Role of Custom PVD Coating in Industrial ApplicationsJanuary 5, 2024In today's fast-paced industrial world, companies are constantly seeking ways to enhance the performance and durability of their products. One effective method that has gained popularity is custom...view Top 10+ Must-have Machinist ToolsFebruary 26, 2024Understanding the right machinist tools can boost productivity. This article highlights three essential tool categories.view

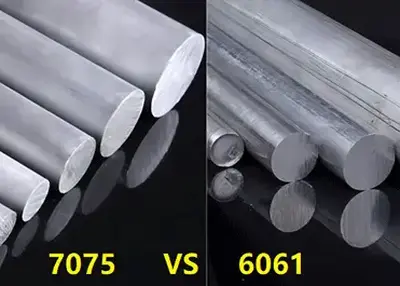

Top 10+ Must-have Machinist ToolsFebruary 26, 2024Understanding the right machinist tools can boost productivity. This article highlights three essential tool categories.view Comparison of 7075 Aluminum Alloy vs 6061 Aluminum AlloyNovember 27, 2023Aluminum alloy is a widely used metal material with the advantages of light weight, high strength, corrosion resistance and recyclability. There are many types of aluminum alloys, and different alloying elements and heat treatment processes affect the properties and uses of aluminum alloys.view

Comparison of 7075 Aluminum Alloy vs 6061 Aluminum AlloyNovember 27, 2023Aluminum alloy is a widely used metal material with the advantages of light weight, high strength, corrosion resistance and recyclability. There are many types of aluminum alloys, and different alloying elements and heat treatment processes affect the properties and uses of aluminum alloys.view Unlocking the Brilliance of Machined Face WheelsNovember 8, 2023Are you ready to elevate your vehicle's style and performance to a whole new level? Look no further! In this comprehensive guide, I'll take you on an exciting journey to explore the world of machined face wheels. From understanding what they are to discovering their stunning aesthetics, identifying suitable vehicle models, and even delving into the intricacies of installation and maintenance, we've got it all covered.view

Unlocking the Brilliance of Machined Face WheelsNovember 8, 2023Are you ready to elevate your vehicle's style and performance to a whole new level? Look no further! In this comprehensive guide, I'll take you on an exciting journey to explore the world of machined face wheels. From understanding what they are to discovering their stunning aesthetics, identifying suitable vehicle models, and even delving into the intricacies of installation and maintenance, we've got it all covered.view How to Use a 5-Axis Machining Center for Titanium Alloy Custom Parts?July 27, 2023As an engineer of five-axis machining centers, I will share with you the method of machining titanium alloy special-shaped parts using a five-axis machining center and the key points of titanium alloy...view

How to Use a 5-Axis Machining Center for Titanium Alloy Custom Parts?July 27, 2023As an engineer of five-axis machining centers, I will share with you the method of machining titanium alloy special-shaped parts using a five-axis machining center and the key points of titanium alloy...view 18-8 Stainless Steel vs 304: What's the Difference and Which One to Choose?December 7, 2023Stainless steel is one of the most widely used materials in the world, thanks to its excellent properties, such as corrosion resistance, strength, durability, and aesthetics. However, not all stainless steel grades are the same.view

18-8 Stainless Steel vs 304: What's the Difference and Which One to Choose?December 7, 2023Stainless steel is one of the most widely used materials in the world, thanks to its excellent properties, such as corrosion resistance, strength, durability, and aesthetics. However, not all stainless steel grades are the same.view