Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. However, steel is also susceptible to corrosion and rust when exposed to moisture and oxygen. Therefore, steel often needs a protective coating to enhance its durability and performance. Two common types of steel coating are galvanized and galvannealed, which both involve applying a layer of zinc to the steel surface. However, these two processes have different characteristics and applications, which may affect your choice of steel for your project.

Galvanized and galvannealed steel are both produced by a hot-dip process, which involves immersing the steel sheet in a molten zinc bath. However, the difference lies in the final step of the process. Galvanized steel is removed from the zinc bath and cooled down, forming a pure zinc coating on the steel surface. Galvannealed steel, on the other hand, is heated again after the zinc bath, causing the zinc and iron to interdiffuse and form a zinc-iron alloy coating on the steel surface. This additional annealing step changes the structure and composition of the coating, resulting in different properties and appearance of the steel.

Galvanized and galvannealed steel have distinct visual differences that can help you identify them. Galvanized steel has a bright, shiny, and spangled appearance, due to the crystallization of the pure zinc coating. Galvannealed steel has a dull, matte, and uniform appearance, due to the smooth and blended zinc-iron alloy coating. Galvanized steel is often preferred for parts that will be highly visible, such as solar panels, roofing, and fencing, as it has a more aesthetic appeal. Galvannealed steel is better suited for internal parts, such as electrical components, ductwork, and cabinets, that do not have strict aesthetic requirements.

Galvanized and galvannealed steel have different physical and chemical properties that affect their performance and suitability for various applications. Some of the main properties are:

• Corrosion resistance: Both types of steel have a high resistance to corrosion, as the zinc coating acts as a sacrificial layer that protects the steel from rusting. However, galvannealed steel has a slightly higher corrosion resistance than galvanized steel, as the zinc-iron alloy coating is more adherent and less prone to cracking or peeling. Galvannealed steel is also more resistant to high temperatures and abrasive environments than galvanized steel.

• Paintability: Galvannealed steel has a better paintability than galvanized steel, as the zinc-iron alloy coating provides a rough and porous surface that allows the paint to bond well. Galvanized steel, on the other hand, has a smooth and non-porous surface that makes the paint adhesion difficult. Therefore, galvanized steel often requires a primer or a surface treatment before painting, while galvannealed steel can be painted directly without any preparation.

• Weldability: Galvannealed steel has a better weldability than galvanized steel, as the zinc-iron alloy coating has a lower melting point and a higher electrical conductivity than the pure zinc coating. This means that galvannealed steel can be welded with less heat and less spatter, resulting in a stronger and cleaner weld. Galvanized steel, on the other hand, has a higher risk of zinc vaporization and porosity during welding, which can affect the weld quality and strength.

• Formability: Galvanized and galvannealed steel have similar formability, as they can be bent, cut, and shaped without compromising the coating integrity. However, galvanized steel may have a slight edge over galvannealed steel in terms of formability, as the pure zinc coating is more ductile and flexible than the zinc-iron alloy coating. Therefore, galvanized steel may be more suitable for complex and intricate shapes, while galvannealed steel may be more suitable for simple and flat shapes.

Galvanized and galvannealed steel have different uses depending on their properties and appearance. Some of the typical uses of both types of steel are:

• Galvanized steel: Galvanized steel is widely used for outdoor applications that require a high corrosion resistance and a bright appearance, such as solar panels, roofing, siding, fencing, gutters, and hardware. Galvanized steel is also used for some indoor applications that do not require painting or welding, such as ducts, pipes, and frames.

• Galvannealed steel: Galvannealed steel is widely used for indoor applications that require a high corrosion resistance and a good paintability and weldability, such as electrical cabinets, panels, boxes, enclosures, and appliances. Galvannealed steel is also used for some outdoor applications that require painting or welding, such as automotive parts, doors, windows, and railings.

Galvanized and galvannealed steel are both types of steel coating that involve applying a layer of zinc to the steel surface. However, they have different production processes, appearances, properties, and uses, which may affect your choice of steel for your project. Galvanized steel has a bright, shiny, and spangled appearance, and is suitable for outdoor applications that require a high corrosion resistance and a bright appearance. Galvannealed steel has a dull, matte, and uniform appearance, and is suitable for indoor applications that require a high corrosion resistance and a good paintability and weldability. Both types of steel have similar formability, but galvanized steel may have a slight edge over galvannealed steel in terms of ductility and flexibility.

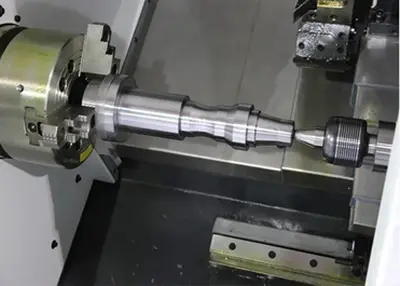

If you are looking for a reliable and professional service for your steel fabrication needs, I recommend you to check out Richconn's CNC machining service. Richconn is a leading precision machine shop that offers high-quality and cost-effective CNC machining solutions for various materials, including steel, aluminum, brass, copper, and plastic. Richconn has a team of experienced and skilled engineers and technicians who can handle any design and specification you may have. Richconn also has a fast turnaround time and a strict quality control system that ensures your satisfaction and success. To learn more about Richconn's CNC machining service, please visit our website or contact our today.

What is CNC Turning and Milling?October 24, 2022With the increasing number of types of CNC lathes, the names of many lathes gradually become difficult to understand. Next, let's understand what is CNC turning-milling compound. Before we underst...view

What is CNC Turning and Milling?October 24, 2022With the increasing number of types of CNC lathes, the names of many lathes gradually become difficult to understand. Next, let's understand what is CNC turning-milling compound. Before we underst...view A Comprehensive Copper Analysis for CNC MachiningJanuary 12, 2024Here are various properties of copper - from its elemental essence, physical prowess, thermal and electrical properties, to applications in CNC machining.view

A Comprehensive Copper Analysis for CNC MachiningJanuary 12, 2024Here are various properties of copper - from its elemental essence, physical prowess, thermal and electrical properties, to applications in CNC machining.view 6 Reasons Why Choosing a Coastal Processing Supplier Can Make Your Business Better!September 11, 2023If you are an efficient and qualified purchasing staff or boss, you need to read my article, which will break your inherent thinking about supply chain and business management. First, let's think about the following points togetherview

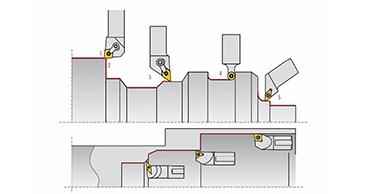

6 Reasons Why Choosing a Coastal Processing Supplier Can Make Your Business Better!September 11, 2023If you are an efficient and qualified purchasing staff or boss, you need to read my article, which will break your inherent thinking about supply chain and business management. First, let's think about the following points togetherview Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view

Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view

American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view Understanding and Improving Modern CNC MillingOctober 11, 2023CNC MillingCNC milling has been around for more than 50 years, but the technology continues to evolve. Recent advances have made it possible to automate the entire process, from design to finished par...view

Understanding and Improving Modern CNC MillingOctober 11, 2023CNC MillingCNC milling has been around for more than 50 years, but the technology continues to evolve. Recent advances have made it possible to automate the entire process, from design to finished par...view

EN

EN

ru

ru