The term CNC stands for "Computer Numerical Control" and CNC machining is defined as a subtractive manufacturing process that typically employs computer-controlled and machine tools to remove layers of material from a stock part (known as a blank or workpiece) and produce a custom-designed part.

The process is applicable to a variety of materials, including metals, plastics, wood, glass, foam and composites, and is used in a variety of industries, such as large-scale CNC machining and CNC finishing of aerospace parts.

High degree of automation and very high productivity. All machining processes, except for blank clamping, can be done by CNC machines. When combined with automatic loading and unloading methods, it is an essential part of an unmanned factory.

CNC machining reduces the operator's labor, improves labor conditions, eliminates marking, multiple clamping and positioning, testing and other processes and their auxiliary operations, effectively improving productivity.

Adaptability to CNC machining objects. Replacement of the machining object, in addition to the replacement of tools and solve the blank clamping method, only reprogramming, without other complex adjustments, shortening the production preparation cycle.

High machining accuracy and stable quality. Machining dimensional accuracy between d0.005-0.01mm, independent of the complexity of the parts, because most of the operations are automatically completed by the machine therefore, improving the size of the batch parts, the precision control of the machine tool is also used in the position detection device, further improving the precision of precision CNC machining.

CNC machining has two main features: first, it can greatly improve the machining accuracy, including machining quality accuracy and machining time error accuracy; second, the repeatability of the machining quality, which can stabilize the machining quality and maintain the quality of the processed parts.

According to the material and requirements of the machining workpiece can choose different processing methods, understand the common machining methods and scope of application, can let us find the most suitable parts processing.

The use of lathes to process parts collectively referred to as cnc turning service. the use of molding cutter, transverse feed, but also can be processed to rotating surface. Turning can also process threaded surfaces, end planes, and eccentric shafts.

Turning accuracy is generally IT11-IT6, surface roughness of 12.5-0.8μm. fine turning, up to IT6-IT5, roughness up to 0.4-0.1μm. turning machining productivity is higher, the cutting process is smoother, simpler tools. smooth, and the tool is simpler.

Scope of application: drilling center hole, drilling, reaming, tapping, turning cylindrical, boring, turning face, turning groove, turning shaped surface, turning taper, knurling, turning threads.

CNC Milling is the use of rotary multi-flute tool (milling cutter) on the milling machine on the workpiece processing methods, the main cutting motion is the rotation of the tool. According to the milling of the main movement speed direction and the workpiece feed direction of the same or the opposite, and is divided into smooth milling and reverse milling.

The horizontal component of the milling force is the same as the feeding direction of the workpiece, and there is generally a gap between the workpiece table feeding screw and the fixed nut, so the cutting force is easy to cause the workpiece and the table to run forward together, so that the feed amount suddenly increases, causing the tool.

Can avoid the phenomenon of scurrying that occurs during forward milling. In reverse milling, the cutting thickness gradually increases from zero, so the cutting edge begins to experience a period of squeezing and sliding on the hardened machined surface, which accelerates the wear of the tool.

Scope of application: milling planes, milling steps, milling grooves, milling shaped surfaces, milling spiral grooves, milling gears, cutting off

Planing generally refers to the processing method of removing excess material on a planing machine by using the planing tool to make reciprocating linear motion relative to the workpiece.

The machining accuracy of planing is generally up to IT8-IT7, the surface roughness is Ra6.3-1.6μm, the flatness of fine planing can be up to 0.02/1000, the surface roughness is 0.8-0.4μm, which is superior for the processing of large castings.

Scope of application: planing plane, planing vertical surface, planing step surface, planing right-angle groove, planing beveled surface, planing dovetail groove, planing D-groove, planing V-groove, planing curved surface, planing keyway in hole, planing rack, planing composite surface.

Grinding is a method of cutting the surface of a workpiece on a grinding machine using a high hardness artificial grinding wheel (grinding wheel) as a tool, and its main motion is the rotation of the grinding wheel.

The precision of grinding processing can reach IT6-IT4, and the surface roughness Ra can reach 1.25-0.01 μm, or even 0.1-0.008 μm. Another feature of grinding processing is that hardened metal materials can be processed, which belongs to the scope of finishing, and is therefore often used as the final Processing procedures. According to the different functions, grinding can also be divided into cylindrical grinding, internal grinding, flat grinding, etc..

Scope of application: External cylindrical grinding, internal cylindrical grinding, surface grinding, profile grinding, dowel grinding, gear grinding, etc.

The process of machining all kinds of internal holes on a drilling machine is called drilling, and it is the most common method of hole machining.

Drilling accuracy is low, generally IT12 ~ IT11, surface roughness is generally Ra5.0 ~ 6.3um, after drilling is often used to reaming and reaming for semi-finishing and finishing. The accuracy of reaming is generally IT9-IT6, and the surface roughness is Ra1.6-0.4μm.

Scope of application: drilling, reaming, reaming, tapping, strontium holes, scraping plane

Boring processing using a boring machine on the existing hole to expand the hole diameter and improve the quality of the processing method, boring processing is based on the rotary movement of the boring tool.

Boring processing precision is high, generally IT9-IT7, surface roughness of Ra6.3-0.8mm, but boring processing productivity is low.

Scope of application: processing of high-precision holes, multiple holes finish machining

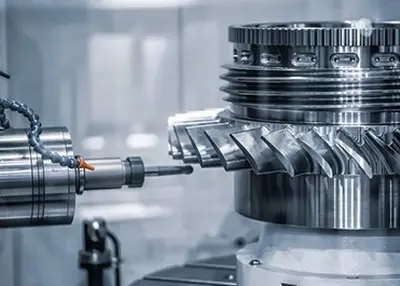

Gear tooth flank processing methods can be divided into two categories: molding method and spreading method.

The machine tool used in the forming method is generally an ordinary milling machine, and the tool is a forming milling cutter, which requires two simple forming motions: rotary motion and linear movement of the tool. The common machine tools used in the spreading method are gear hobbing machines and gear shaping machines.

Scope of application: Gears, etc.

Three-dimensional surface machining, mainly using profiling and CNC milling methods or special processing methods.

Scope of application: complex surface parts

EDM utilizes the high temperature generated by the instantaneous spark discharge between the tool electrode and the workpiece electrode to melt the surface material of the workpiece to realize the processing.

Scope of application:

① Processing of hard, brittle, tough, soft and high melting point conductive materials;

② processing semiconductor materials and non-conductive materials;

③ processing of various types of holes, curved holes and small holes;

④ processing a variety of three-dimensional curved cavities, such as forging molds, die-casting molds, plastic mold chamber;

⑤ used for cutting, cutting and surface strengthening, engraving, printing nameplates and marking.

Electrolytic machining is the use of metal in the electrolytic solution to produce anodic dissolution of electrochemical principles on the workpiece forming a method of processing.

The workpiece is connected to the positive pole of the DC power supply, the tool is connected to the negative pole, keep a narrow gap between the two poles (0.1mm ~ 0.8mm). Electrolyte with a certain pressure (0.5MPa ~ 2.5MPa) flows through the gap between the two poles at a high speed of 15m/s ~ 60m/s).

Scope of application: Processing of molded holes, cavities, complex molded surfaces, small-diameter deep holes, rifling, as well as deburring and engraving.

Laser processing of workpieces is accomplished by laser processing machines. Laser processing machine usually consists of laser, power supply, optical system and mechanical system.

Scope of application: small hole processing of diamond wire drawing dies, watch and clock gemstone bearings, porous skin of dispersive air-cooled punches, engine injection nozzles, aero-engine blades, etc., as well as cutting and processing of a variety of metallic and non-metallic materials.

Ultrasonic processing is the use of ultrasonic frequency (16KHz ~ 25KHz) vibration of the end face of the tool impact on the working fluid in the suspension of the abrasive, by the abrasive particles on the surface of the workpiece to realize the workpiece processing of a method of impact grinding.

Generally, CNC-machined parts have high precision, so CNC-machined parts are mainly used in the following industries:

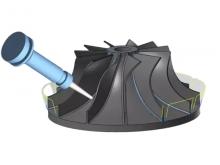

Aerospace requires highly accurate and repeatable components, including turbine blades in engines, tooling used to make other components, and even combustion chambers used in rocket engines.

The automotive industry needs to make high-precision molds for casting components such as engine seats or machining high-tolerance parts such as pistons. Gantry machines cast clay modules, which are used in the design phase of automobiles.

The military industry uses high-precision components with tight tolerances, including missile components, gun barrels, and more. All machined components in the military industry benefit from the precision and speed of CNC machines.

Medical implantable devices are often designed to fit the shape of a human organ and must be manufactured from high grade alloys. Since there are no manual machines capable of generating such shapes, CNC machines have become a necessity.

The energy industry encompasses all areas of engineering, from steam turbines to cutting-edge technologies such as nuclear fusion. Steam turbines require high-precision turbine blades to maintain equilibrium in the turbine, and the R&D plasma suppression cavities in nuclear fusion have complex shapes made from advanced materials that require the support of CNC machines.

Machining has evolved to the present day, and a wide variety of machining processes have been developed to follow the increased demands of the market. When you choose a machining process, you can consider from various aspects: including the shape of the surface of the machined workpiece, dimensional accuracy, positional accuracy, surface roughness and so on.

Choosing the most appropriate process can ensure the quality of the workpiece and processing efficiency under the minimum investment, in order to maximize the benefits generated.

Richconn is your preferred CNC machining service provider. We combine advanced computer numerical control (CNC) technology with extensive industry experience to provide you with high-quality, customized solutions. Whether you need to manufacture parts, prototypes or customized pieces, we can meet your needs.

Our team of professional engineers and technical experts are dedicated to providing the best manufacturing solution for your project. Whether you are producing small batches or large scale production, we ensure high precision and efficiency.

When you choose Richconn, you will enjoy the following advantages:

Highly precise CNC machining to ensure product quality and consistency.

Fast delivery to meet your urgent project needs.

Competitive pricing, giving you excellent value for money.

Customization, where we will tailor a solution to your requirements.

Regardless of the size of your project, Richconn will provide you with exceptional CNC machining services. Partner with us and let's bring your ideas to life together. Contact us to learn more and get a free quote.

Machining Commonly Used 24 Kinds of MaterialsOctober 23, 2023Can be used for CNC machining, mold processing of more than a hundred kinds of materials, metal, plastic, but according to the actual needs of different, each material use as well as the demand varies, the most commonly used 24 kinds of materials.view

Machining Commonly Used 24 Kinds of MaterialsOctober 23, 2023Can be used for CNC machining, mold processing of more than a hundred kinds of materials, metal, plastic, but according to the actual needs of different, each material use as well as the demand varies, the most commonly used 24 kinds of materials.view What Are the Types of Metal Surface Finish?September 16, 2022Machining surface finishing is an important processing procedure in machining. Machining surface finish can play an important role in protecting and beautifying the workpiece. In machining, there are ...view

What Are the Types of Metal Surface Finish?September 16, 2022Machining surface finishing is an important processing procedure in machining. Machining surface finish can play an important role in protecting and beautifying the workpiece. In machining, there are ...view CNC Machining and AI: How Artificial Intelligence is Impacting the FieldOctober 25, 2023Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:view

CNC Machining and AI: How Artificial Intelligence is Impacting the FieldOctober 25, 2023Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:view Unlocking the Infinite Potential of CNC Milling MaterialsFebruary 29, 2024In the intricate tapestry of CNC milling materials, the careful selection of materials emerges as the linchpin, dictating the success and precision of every project.view

Unlocking the Infinite Potential of CNC Milling MaterialsFebruary 29, 2024In the intricate tapestry of CNC milling materials, the careful selection of materials emerges as the linchpin, dictating the success and precision of every project.view What Are Tolerances? How Are Tolerances Determined When Designing Machinery?October 26, 2023Tolerance is precise machining and design, the actual parameter values of the parts of the allowable amount of change, such as a certain part of the upper and lower limits were 100, 60, then its tolerance is 40; if the upper and lower limits were +100, -100, then its tolerance is 200.view

What Are Tolerances? How Are Tolerances Determined When Designing Machinery?October 26, 2023Tolerance is precise machining and design, the actual parameter values of the parts of the allowable amount of change, such as a certain part of the upper and lower limits were 100, 60, then its tolerance is 40; if the upper and lower limits were +100, -100, then its tolerance is 200.view Four Requirements for Medical Component ProcessingMay 22, 2023For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processe...view

Four Requirements for Medical Component ProcessingMay 22, 2023For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processe...view