In our first section, we'll provide an in-depth introduction to machined carbon fiber. We'll answer the fundamental question, "What is machined carbon fiber?" and delve into its history, and compare it to other materials. By the end of this section, you'll have a solid foundation to build upon.

Machined carbon fiber is a composite material composed of carbon fibers embedded in a matrix material, typically epoxy resin. It is renowned for its exceptional mechanical properties, making it a preferred choice for various applications.

Carbon fibers are made from organic polymers and are processed to produce a material with high tensile strength and stiffness. These fibers are then woven into fabric or laid down in sheets. The resulting material is both lightweight and incredibly strong, with a density significantly lower than that of steel, while still maintaining impressive strength.

The history of machined carbon fiber dates back to the mid-20th century. Initially developed for military and aerospace applications, it gradually found its way into various industries.

Here is a timeline of significant developments in the history of machined carbon fiber:

| Year | Milestone in Machined Carbon Fiber |

|---|---|

| 1958 | Carbon fibers were first developed using rayon as the precursor material. |

| 1960s | Experimental use of carbon fiber composites in aerospace applications, including the nose cone of missiles. |

| 1970s | Widespread use in military aircraft, leading to the popularization of the material. |

| 1980s | Carbon fiber composites became more accessible for various industries, including automotive and sports equipment. |

| 1990s | Advancements in production methods and increased use in high-performance sports cars. |

| 21st Century | Ongoing innovations and expanding applications across multiple sectors. |

Machined carbon fiber stands out when compared to other materials such as steel, aluminum, and plastics. Let's make a detailed comparison to understand its advantages.

One of the most significant advantages of machined carbon fiber is its impressive strength-to-weight ratio. It is much stronger than steel, yet significantly lighter. This characteristic makes it ideal for applications where weight reduction is critical, such as in aerospace and sports equipment.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Strength-to-Weight Ratio (MPa/g/cm³) |

|---|---|---|---|

| Machined Carbon Fiber | 2,000 - 5,000+ | 1.5 - 1.6 | 1,333 - 3,333+ |

| Steel | 370 - 2,000 | 7.7 - 7.9 | 48 - 256 |

| Aluminum | 150 - 500 | 2.7 | 55.6 - 185.2 |

| Plastic (ABS) | 30 - 60 | 1.05 - 1.3 | 28.8 - 46.2 |

This table clearly demonstrates the superior strength-to-weight ratio of machined carbon fiber compared to traditional materials.

Another advantage of machined carbon fiber is its excellent corrosion resistance. Unlike metals, it doesn't corrode or rust, making it suitable for applications where exposure to harsh environments is a concern.

In applications where corrosion is a significant concern, such as marine and chemical industries, machined carbon fiber provides longevity and durability that other materials can't match.

Machined carbon fiber exhibits unique electrical properties. It can act as both a conductor or an insulator, depending on the specific type of carbon fiber used and its manufacturing process. This versatility is highly valuable in applications where controlled electrical conductivity is required.

Machined carbon fiber is renowned for its remarkable properties. We'll explore seven key characteristics in detail:

Machined carbon fiber's exceptional strength-to-weight ratio sets it apart. It's incredibly strong while being significantly lighter than traditional materials like steel. This characteristic makes it a game-changer in industries where weight reduction is crucial.

Machined carbon fiber's tensile strength typically ranges from 2,000 to over 5,000 MPa, whereas its density falls between 1.5 to 1.6 g/cm³. This results in an outstanding strength-to-weight ratio, making it a top choice for aerospace components and high-performance sports equipment.

Machined carbon fiber's resistance to corrosion is a game-changer in industries where exposure to harsh environments is common. Unlike metals, machined carbon fiber doesn't corrode or rust. Its resistance to chemical degradation and environmental factors makes it a durable choice for applications in marine, chemical, and offshore industries.

The electrical properties of machined carbon fiber are fascinating. Depending on the specific type of carbon fiber and manufacturing process, it can either conduct electricity or act as an insulator. This versatility finds use in industries where controlled electrical conductivity is crucial.

Carbon fiber reinforced composites can be engineered to have varying levels of electrical conductivity, making them suitable for applications in aerospace, automotive, and even electronics, where EMI shielding or electrical insulation is needed.

Machined carbon fiber exhibits impressive temperature stability. It can withstand extreme temperatures, making it a valuable material for applications subjected to high heat or extreme cold. Its resistance to thermal expansion and contraction is highly advantageous in the aerospace, automotive, and energy sectors.

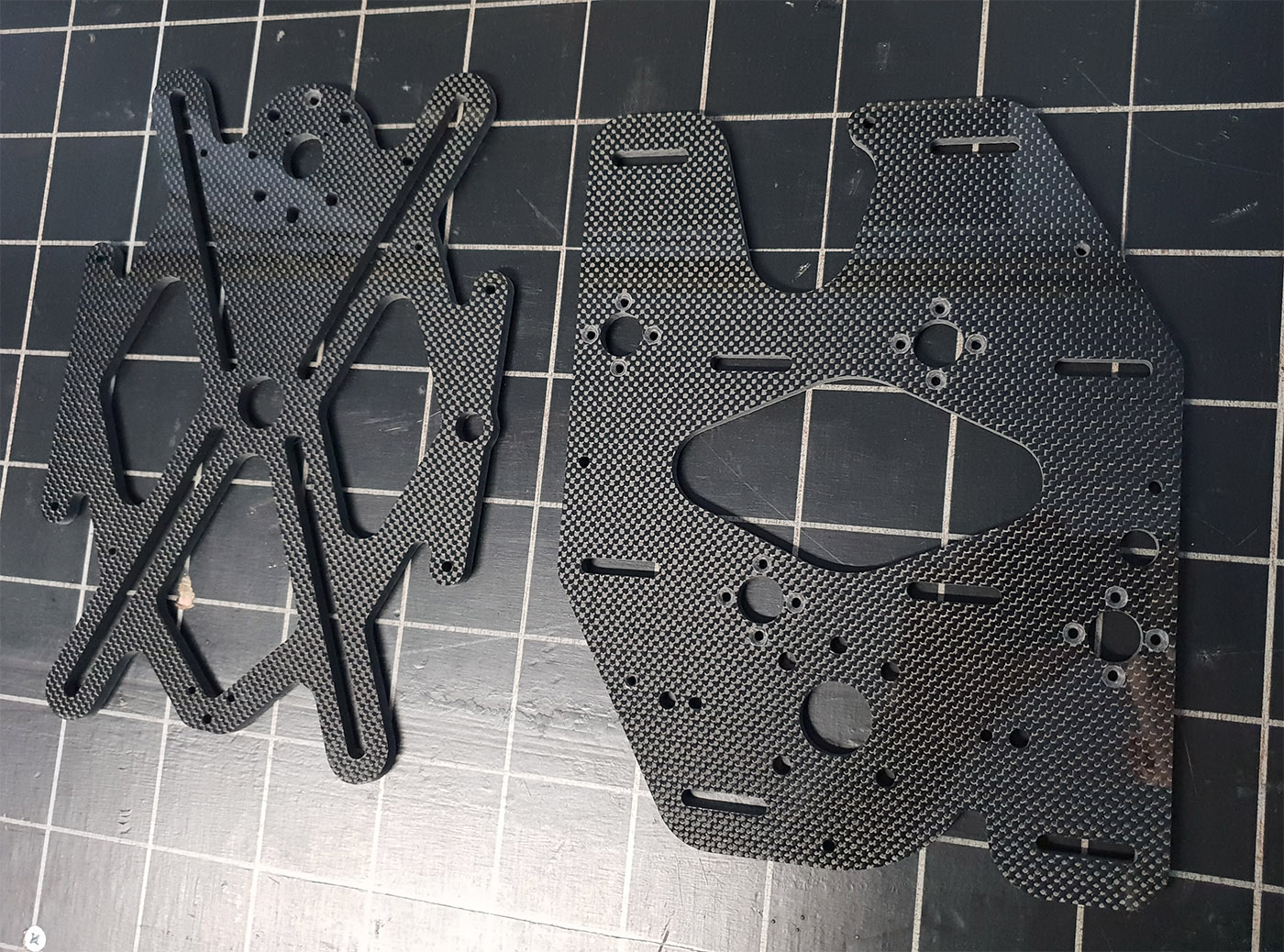

Machined carbon fiber is known for its machinability, but this aspect deserves a closer look. The material can be processed using various methods, including CNC machining, water jet cutting, and abrasive cutting. Its machinability depends on factors like fiber orientation and tool selection.

CNC machining is a widely used method for precision work with machined carbon fiber. The ability to create intricate shapes and fine details makes it an ideal choice for aerospace components, automotive parts, and medical devices.

Machined carbon fiber offers high rigidity, ensuring structural integrity in various applications. Its stiffness allows for precise control in complex designs, reducing the risk of deformation under load. This quality is particularly advantageous in the automotive and sporting goods industries.

Fatigue resistance is a critical property for components that experience repetitive loading. Machined carbon fiber excels in this area, with excellent fatigue resistance. This makes it suitable for applications where durability is essential, such as wind turbine blades and robotics.

By now, you should have a comprehensive understanding of machined carbon fiber's characteristics and why it's highly regarded in numerous industries.

The versatility of machined carbon fiber extends to various industries, thanks to its exceptional properties. In this section, we will delve into the specific applications where this material excels:

Machined carbon fiber is widely used in the aerospace industry due to its lightweight and high-strength properties. It is utilized in the manufacturing of aircraft components, including:

Aircraft Fuselage: Carbon fiber composites are used to construct lightweight yet durable aircraft fuselages, reducing fuel consumption and enhancing overall performance.

Wings and Winglets: Carbon fiber is employed to design aerodynamic wings and winglets, improving fuel efficiency and reducing emissions.

Interior Components: From cabin interiors to seating, the aerospace industry leverages carbon fiber for its weight savings and aesthetic appeal.

The automotive industry has embraced machined carbon fiber for its potential to enhance fuel efficiency, reduce emissions, and improve overall performance. Key applications include:

Body Panels: Carbon fiber reinforced plastics are used in the production of lightweight body panels, reducing vehicle weight and improving fuel economy.

Suspension Components: Carbon fiber components are integrated into suspensions to reduce unsprung weight and enhance handling.

High-Performance Vehicles: Carbon fiber is a staple in the design of high-end sports cars and supercars, optimizing performance.

Machined carbon fiber has revolutionized the world of sports equipment. It is used in various sports gear, such as:

Tennis Rackets: Carbon fiber provides the perfect balance of strength and flexibility, enhancing control and power.

Golf Clubs: Golfers benefit from carbon fiber shafts that deliver improved swing speed and accuracy.

Bicycles: Carbon fiber frames and components reduce weight and increase stiffness, resulting in faster and more efficient rides.

Hockey Sticks: Players experience improved puck control and power with carbon fiber sticks.

Skis and Snowboards: Carbon fiber constructions enhance maneuverability and performance on the slopes.

Machined carbon fiber is increasingly being used in the medical field for its unique properties, including:

Prosthetic Limbs: Carbon fiber prosthetics offer a lightweight and durable alternative to traditional materials, improving mobility and comfort for amputees.

X-ray Tables: The material's radiolucency makes it suitable for X-ray and imaging tables.

Wheelchairs: Carbon fiber wheelchairs are lighter and more maneuverable, enhancing the quality of life for users.

In the energy sector, machined carbon fiber plays a significant role in various applications, including:

Wind Turbine Blades: Carbon fiber composites are used to create longer and more efficient wind turbine blades, increasing energy production.

Oil and Gas: Components exposed to harsh chemical and environmental conditions benefit from carbon fiber's corrosion resistance.

Solar Panels: Carbon fiber structures are used to support and position solar panels, optimizing energy capture.

Machined carbon fiber finds applications in numerous other fields, such as:

Construction: Carbon fiber reinforced concrete offers enhanced structural integrity and durability.

Electronics: Carbon fiber is used for EMI shielding and static discharge in electronic devices.

Marine: It is employed in boat hulls and components due to its resistance to saltwater corrosion.

Machining machined carbon fiber requires precision and expertise. Various methods are employed to shape and fabricate components from this material. In this section, we will explore the details of machining machined carbon fiber:

Several methods are used to machine carbon fiber composites. These methods include:

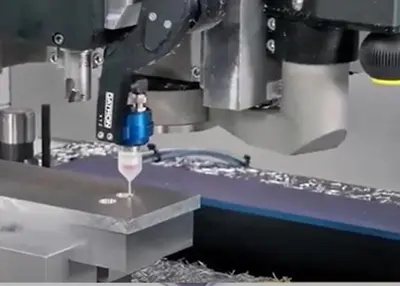

CNC Machining: Computer Numerical Control (CNC) machining is a widely used method for precision work with machined carbon fiber. CNC machines are programmed to cut, drill, and shape carbon fiber components with high accuracy. This method is suitable for complex and intricate designs.

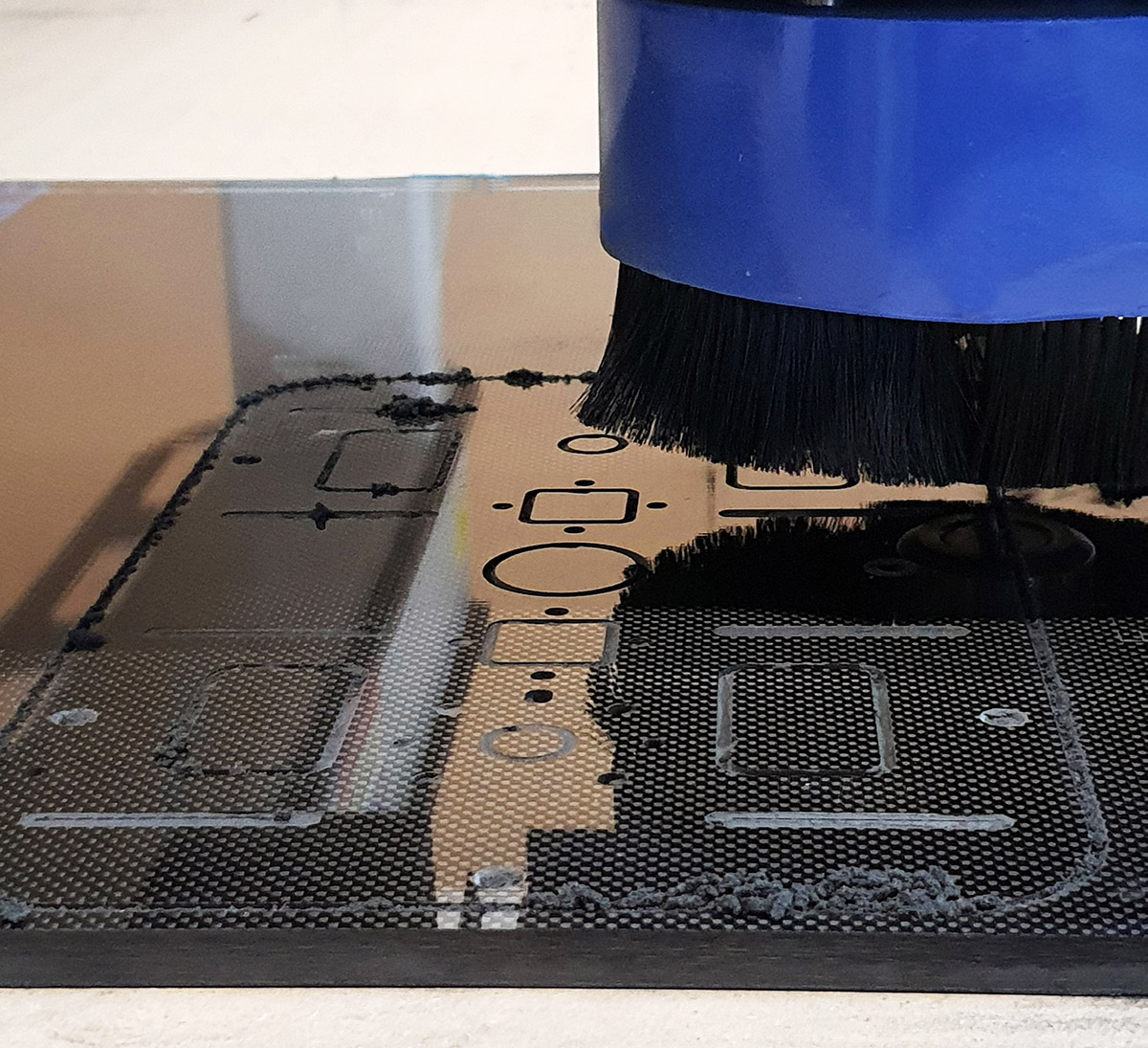

Water Jet Cutting: Water jet cutting uses a high-pressure stream of water mixed with abrasive particles to cut carbon fiber. It is ideal for materials that may be sensitive to heat, such as thermoset composites like carbon fiber. Water jet cutting provides a clean and precise cut without generating heat-affected zones.

Abrasive Cutting: Abrasive cutting involves the use of abrasive tools or discs to cut carbon fiber. This method is suitable for cutting carbon fiber tubes, sheets, and flat components. It is a cost-effective method for basic shapes and designs.

CNC machining is particularly compatible with machined carbon fiber due to its precision and versatility. CNC machines are equipped with advanced software that can interpret complex 3D models and translate them into precise cuts and shapes. This compatibility is essential for applications that demand intricate designs and tight tolerances.

CNC machining offers several advantages when working with machined carbon fiber:

Precision: CNC machines can achieve high levels of precision, ensuring that carbon fiber components meet exact specifications.

Complex Geometry: CNC machining can handle complex and intricate designs, enabling the production of custom components.

Consistency: CNC machines offer consistent quality across production runs, reducing the likelihood of variations in parts.

Reduced Waste: CNC machining produces minimal waste, optimizing material usage and reducing costs.

CNC machining service providers, like Richconn, play a critical role in the process of machining machined carbon fiber. These companies have the expertise and equipment needed to handle carbon fiber materials effectively.

As a CNC machining service provider, Richconn offers the following services:

Material Selection: Advising on the most suitable carbon fiber material for specific applications.

Design Assistance: Collaborating on the design and optimization of components to achieve the desired performance.

Precision Machining: Utilizing CNC machines to produce high-precision components with strict adherence to specifications.

Quality Control: Ensuring that the machined carbon fiber components meet rigorous quality standards.

Cost-Efficiency: Maximizing the cost-effectiveness of machining projects.

Working with a CNC machining service provider like Richconn ensures that machined carbon fiber components are produced with the highest level of precision and quality.

In this section, we will explore successful case studies that demonstrate the effectiveness of machined carbon fiber in various applications. These examples highlight the material's performance and its impact on different industries:

A leading aircraft manufacturer incorporated machined carbon fiber components in the design of their aircraft. By replacing traditional metallic parts with carbon fiber composites, they achieved a significant reduction in overall weight. This translated into improved fuel efficiency and reduced emissions, making their aircraft more eco-friendly and cost-effective. The machined carbon fiber components provided the necessary structural integrity while keeping weight to a minimum.

An automotive company introduced carbon fiber-reinforced body panels in their high-performance sports car models. The integration of machined carbon fiber reduced the vehicle's weight, enhancing acceleration and handling. Drivers experienced improved fuel efficiency and a thrilling driving experience. The lightweight and high-strength properties of machined carbon fiber made it a game-changer in the automotive industry, paving the way for more eco-friendly and powerful vehicles.

A professional tennis player switched to a carbon fiber tennis racket, taking advantage of its superior strength and lightweight design. The carbon fiber racket provided enhanced control, power, and maneuverability on the court. The player's performance improved, and they credited the racket for their success. This case study illustrates how machined carbon fiber contributes to excellence in sports equipment.

An orthopedic clinic introduced machined carbon fiber prosthetic limbs to their patients. These carbon fiber prosthetics are not only lightweight but also highly durable. Patients experienced improved mobility and comfort. The prosthetic limbs allowed them to lead more active lives, thanks to the material's strength and adaptability. This case study demonstrates the positive impact of machined carbon fiber on the quality of life for amputees.

Wind turbine manufacturers adopted machined carbon fiber composites for the construction of longer and more efficient wind turbine blades. The lightweight yet strong nature of carbon fiber allowed for increased blade length, resulting in improved energy production. This shift towards carbon fiber materials contributed to the growth of the renewable energy sector and more sustainable power generation.

Boat builders utilized machined carbon fiber to construct boat hulls, offering improved performance and durability. Carbon fiber's resistance to saltwater corrosion and lightweight properties make it an ideal choice for marine applications. This case study showcases the advantages of carbon fiber in the nautical engineering industry.

These real-world case studies underscore the versatility and advantages of machined carbon fiber in diverse sectors. The material's exceptional properties have driven innovation and improved the performance and sustainability of products and applications.

The world of machined carbon fiber is continually evolving, with ongoing research and developments that push the boundaries of what's possible with this remarkable material. In this section, we'll provide insights into the latest innovations and emerging trends:

The field of machined carbon fiber technology is witnessing several innovations, including:

Advanced Resin Systems: Researchers are developing advanced resin systems that enhance the performance of carbon fiber composites. These resins offer improved adhesion, impact resistance, and temperature stability.

Nanocomposites: The integration of nanomaterials with carbon fiber composites is a growing area of interest. These nanocomposites offer even greater strength and unique electrical properties.

Recyclable Carbon Fiber: Sustainable manufacturing methods for recycling and reusing carbon fiber composites are being explored. These methods aim to reduce waste and environmental impact.

The future of machined carbon fiber holds exciting possibilities:

Smart Materials: Research is underway to develop smart materials using machined carbon fiber, which can adapt to changing conditions and provide real-time data on structural health.

3D Printing: 3D printing with carbon fiber-reinforced filaments is becoming more accessible, allowing for rapid prototyping and customized component manufacturing.

Wider Range of Applications: As technology advances, the range of applications for machined carbon fiber continues to expand, including potential uses in the construction industry, electronics, and more.

Sustainability: The industry is focusing on sustainable production methods and recycling processes to reduce the environmental impact of carbon fiber composites.

As new research and developments continue to shape the field, machined carbon fiber will become an even more essential and versatile material across various industries.

Selecting the ideal machined carbon fiber supplier is a crucial decision that can greatly impact the success of your project. In this section, we'll guide you through the process of finding the right supplier and balancing price with quality:

When looking for a machined carbon fiber supplier, consider the following factors:

Experience and Expertise: Look for suppliers with a proven track record in working with machined carbon fiber. Experience often translates to quality and reliability.

Quality Standards: Ensure that the supplier adheres to strict quality control standards. Certification and adherence to industry-specific quality standards are a positive sign.

Customization: Evaluate the supplier's ability to provide custom solutions tailored to your project's requirements. The flexibility to adapt to your needs is invaluable.

Materials Offered: A reputable supplier should offer a range of machined carbon fiber materials, each suitable for different applications. Make sure the supplier can provide the specific material you need.

Lead Times: Consider the supplier's lead times and ability to meet your project's timelines. Timely delivery is crucial for project success.

Cost Transparency: Seek a supplier that provides transparent pricing and cost breakdowns. Avoid hidden fees or unexpected charges.

Balancing price with quality is a critical aspect of choosing a machined carbon fiber supplier. Keep these tips in mind:

Total Cost of Ownership: Consider the total cost of ownership, which includes not only the initial price but also factors like material quality, lead times, and durability.

Quality Assurance: Opt for a supplier that prioritizes quality. While cost is a significant consideration, cutting corners on quality may lead to long-term issues and higher costs down the road.

Request Multiple Quotes: Don't settle for the first quote you receive. Request quotes from multiple suppliers to compare prices and services.

Consider Long-Term Partnerships: Building a long-term relationship with a reliable supplier can lead to cost savings and better service over time.

Sample Orders: If possible, request sample orders to evaluate the material's quality before committing to a larger project.

Negotiation: Don't hesitate to negotiate terms and prices with potential suppliers. They may be willing to work with you to meet your budget while delivering quality products.

As a CNC machining service provider, Richconn is dedicated to serving your machined carbon fiber needs. We offer the following advantages:

Extensive Experience: With years of experience in CNC machining and a deep understanding of machined carbon fiber, we are well-equipped to deliver top-quality components.

Quality Commitment: We maintain high-quality standards in all our projects, ensuring that our clients receive superior products that meet their specifications.

Custom Solutions: We specialize in providing custom solutions tailored to your specific requirements, from material selection to design assistance.

Competitive Pricing: We offer competitive pricing while maintaining the highest quality standards, ensuring you receive value for your investment.

On-Time Delivery: Timely delivery is a priority for us, and we work diligently to meet project deadlines.

Choosing the right supplier, like Richconn, ensures that your machined carbon fiber components are of the highest quality and meet your project's requirements while staying within your budget.

This comprehensive guide has provided you with a deep understanding of machined carbon fiber, its characteristics, applications, machining methods, real-world case studies, and the latest developments. With this knowledge, you are well-prepared to make informed decisions and explore the countless possibilities that machined carbon fiber offers. Whether you are in aerospace, automotive, sports equipment, medical devices, energy, or any other industry, machined carbon fiber is a material that continues to drive innovation and improve the performance of various products and applications.

6 Benefits of Partnering With a Trusted CNC CompanySeptember 13, 2023Why choose a CNC company to partner with? Let’s explore the advantages of partnering with a CNC company for precision machining and top-quality parts.view

6 Benefits of Partnering With a Trusted CNC CompanySeptember 13, 2023Why choose a CNC company to partner with? Let’s explore the advantages of partnering with a CNC company for precision machining and top-quality parts.view Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view

Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view What Are The 3-Axis, 4-Axis, And 5-Axis In Cnc Machining, And What Is The Difference Between Them?June 21, 20223-axis CNC machining, 4-axis CNC machining, and 5-axis CNC machining are terms that are often heard in our industry work. Some users can't tell. For these types of CNC machining, there are still C...view

What Are The 3-Axis, 4-Axis, And 5-Axis In Cnc Machining, And What Is The Difference Between Them?June 21, 20223-axis CNC machining, 4-axis CNC machining, and 5-axis CNC machining are terms that are often heard in our industry work. Some users can't tell. For these types of CNC machining, there are still C...view Common Inspection Tools and Methods for CNC Parts: Ensuring Quality and PrecisionJune 21, 2024Learn about common inspection tools and methods in CNC machining, such as calipers, micrometers, gauges, projectors, and CMM. Discover how to use these tools accurately for quality control.view

Common Inspection Tools and Methods for CNC Parts: Ensuring Quality and PrecisionJune 21, 2024Learn about common inspection tools and methods in CNC machining, such as calipers, micrometers, gauges, projectors, and CMM. Discover how to use these tools accurately for quality control.view Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view

Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view What Are the Processing Principles of Precision Machining?December 30, 2022What are the processing principles of precision CNC machining? What safety precautions are there when performing precision CNC machining?1. Processing principles of precision NC machining (1) In order...view

What Are the Processing Principles of Precision Machining?December 30, 2022What are the processing principles of precision CNC machining? What safety precautions are there when performing precision CNC machining?1. Processing principles of precision NC machining (1) In order...view