In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum sheet technology relies on its high precision, efficiency, and flexibility, and has been widely applied in various industries. This article will delve into CNC cutting aluminum sheet technology, its advantages, applications, and its significance in modern manufacturing.

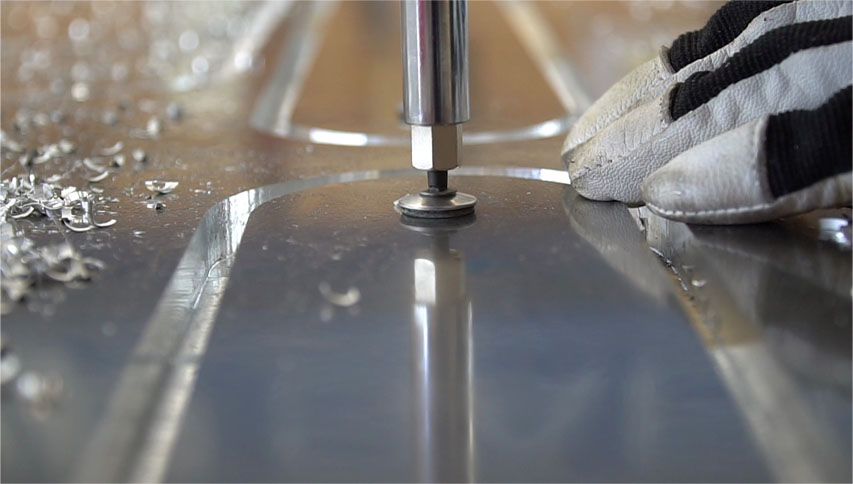

CNC cutting aluminum sheet technology is an automated numerical control processing technique that precisely cuts aluminum sheets through computer programs to achieve complex shapes and high precision cutting. CNC cutting machines employ different methods like tungsten inert gas cutting, laser cutting, or plasma cutting to efficiently process aluminum sheets with high automation and intelligence.

Use suitable CNC machine tools and cutting tools. Cutting aluminum alloy requires higher spindle speeds and lower feed rates compared to cutting steel. Your CNC machine tool needs to have enough rigidity to withstand the cutting force of aluminum. Cobalt steel cutting tools are most suitable for stainless steel.

Secure the aluminum alloy sheet properly. Compared to other metals, aluminum alloy generates more vibration and shaking during processing. Use fixtures, mechanical devices, or vacuum suction to securely fix the sheet. If possible, apply tension to prevent vibration.

Use appropriate feed rates and spindle speeds. For a 1/4-inch end mill, the typical spindle speed range is 15,000-20,000rpm, and the feed rate is 8-12ipm. Too slow can cause chip buildup on the tool, while too fast can lead to premature tool wear. Start with conservative values and gradually increase until optimal.

Use compressed air to blow away chips. If chips accumulate in the cutting path, it may re-cut the workpiece. Use compressed air to blow away chips regularly. Before restarting the program, use a brush to clear any chips on the workpiece surface.

Prepare the workpiece surface. Wipe with solvent to remove any oil stains, dirt, or oxide layers before processing. This can achieve better cutting results and avoid contaminating the workpiece.

Use lubricants/coolants. Aluminum alloy quickly generates heat. Spraying lubricants or coolants can help dissipate heat, prevent chip welding, and prolong tool life.

Take light cutting and multiple-layer cutting. Adopt shallower cutting to limit the tool load. Avoid cutting to full depth in a single pass, allowing intermittent cutting for heat dissipation.

Regularly check the cutting tools. The soft nature of aluminum alloy can quickly wear out cutting tools. Check for any chips, buildup, or wear on the tools, and replace them as necessary. Be careful when tightening the tools to prevent loosening.

High Precision: CNC cutting technology allows precise control of the cutting equipment's movements, achieving sub-millimeter cutting precision, ensuring the machining quality of aluminum sheets.

High Efficiency: CNC cutting aluminum sheet technology can achieve continuous high-speed cutting, saving a considerable amount of labor and time costs, and enhancing production efficiency.

Flexibility: CNC cutting technology can flexibly adapt to various product requirements, suitable for producing aluminum sheets of different shapes and sizes.

Waste Reduction: CNC cutting technology maximizes the utilization of aluminum sheet materials, reducing waste and lowering production costs.

In the aerospace industry, aluminum alloys are extensively used to manufacture aircraft structural components, cabin walls, wings, fuel tanks, and other parts due to their lightweight, high strength, and corrosion resistance. CNC cutting technology enables precise cutting of complex shapes, ensuring the precise processing of aerospace components. In the aerospace industry, accurate dimensions and high-quality components are vital, and CNC cutting aluminum sheet technology meets these requirements, enhancing aircraft performance and safety.

The automotive industry places a high demand on vehicle lightweight design and fuel efficiency. Aluminum alloys are widely used in automotive bodies and components due to their lightweight and high strength. CNC cutting technology can accurately cut aluminum sheets to produce body panels, doors, engine hoods, and other components to meet the automotive industry's high-quality and high-precision requirements. By using CNC cutting technology, automotive manufacturers can achieve vehicle lightweight designs, thereby improving fuel efficiency and performance.

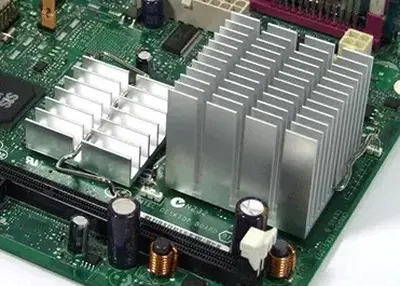

Aluminum sheets are used in the electronics and electrical industry to manufacture heat sinks, casings, and heat dissipation fins, among other components. The stability and performance of electronic devices are often affected by heat dissipation effectiveness. CNC cutting technology can customize various complex-shaped heat dissipation fins according to different electronic product requirements, improving heat dissipation efficiency and ensuring the normal operation of electronic devices. Moreover, CNC cutting technology can produce casings and panels, making electronic products more aesthetically pleasing and refined.

In the architectural decoration field, aluminum sheets are widely used in curtain walls, ceilings, aluminum alloy doors, and windows, etc. CNC cutting technology can cut decorative aluminum sheets according to design requirements, making architectural exteriors more unique and aesthetically pleasing. The high precision and flexibility of CNC cutting technology enable architects to achieve various complex designs, enhancing the artistic value and appeal of buildings.

The widespread application of CNC cutting aluminum sheet technology not only improves production efficiency and product quality but also drives the development of modern manufacturing. It brings more innovations and possibilities to various industries, promoting the upgrading and progress of industrial technology. CNC cutting technology also promotes the development of manufacturing towards intelligence and automation, enhancing industrial competitiveness.

CNC cutting aluminum sheet technology serves as a significant tool in modern manufacturing. With its high precision, efficiency, and flexibility, this type of CNC machining service is widely applied in aerospace, automotive, electronics, and construction industries. It not only enhances product quality and production efficiency but also promotes the development and progress of modern manufacturing. With technology constantly evolving, CNC cutting technology will play an increasingly important role in driving manufacturing towards higher levels.

Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view

Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view 10 Common Metal Materials for CNC Machining & Typical UsesApril 12, 2024Here are 10 common metal materials for CNC machining and their typical uses. Read on and get useful suggestions on how to select suitable metal materials for your project.view

10 Common Metal Materials for CNC Machining & Typical UsesApril 12, 2024Here are 10 common metal materials for CNC machining and their typical uses. Read on and get useful suggestions on how to select suitable metal materials for your project.view CNC Machining China: How to Choose the Best Online CNC Machining Services?September 5, 2023China has emerged as a prominent player in the CNC machining industry due to its global manufacturing leadership. The country is home to a plethora of CNC machining and rapid prototyping shops that ca...view

CNC Machining China: How to Choose the Best Online CNC Machining Services?September 5, 2023China has emerged as a prominent player in the CNC machining industry due to its global manufacturing leadership. The country is home to a plethora of CNC machining and rapid prototyping shops that ca...view Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view

Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view

The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view Drill and Tap Specification ChartNovember 17, 2023In CNC machining, the usual process is to use a drill bit to drill a hole in the workpiece and then use a tap of the appropriate size to cut the desired threads in the hole. This ensures that the threads match the design requirements and can ensure that the threads fit correctly with other components.view

Drill and Tap Specification ChartNovember 17, 2023In CNC machining, the usual process is to use a drill bit to drill a hole in the workpiece and then use a tap of the appropriate size to cut the desired threads in the hole. This ensures that the threads match the design requirements and can ensure that the threads fit correctly with other components.view

EN

EN

ru

ru