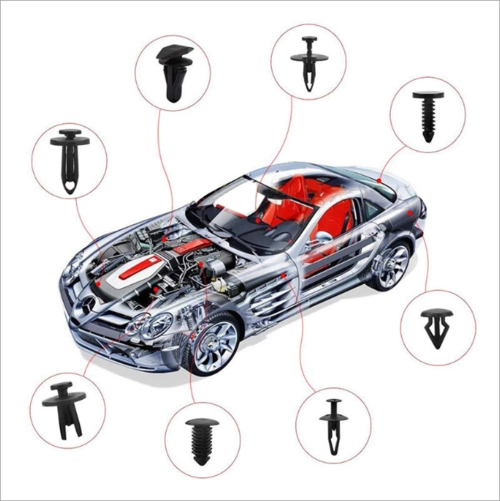

Automotive fasteners are an essential component in the construction and maintenance of vehicles. As a result, automotive part manufacturing relies on high-tolerance designs that include connecting mechanism elements, such as fasteners. Fasteners are essential to the manufacturing of automotive parts because they facilitate the assembly and operation of automotive components. Based on the components, composition, and intended uses, there are various types of automotive fasteners. Let’s have a look!

Generally, when it comes to automobile projects, two categories of fastener materials are commonly used. Each has its attributes and functions.

Metal fasteners are commonly used in automotive applications due to their strength and durability. They are often used in applications where weight reduction is a priority, such as for fastening interior components.

Plastic fasteners are also used in certain automotive applications, particularly in non-structural or low-load-bearing components. Plastic fasteners offer advantages such as being lightweight, cost-effective, and resistant to corrosion. They are commonly made from materials such as nylon, polypropylene, and polycarbonate.

Aside from material classification, another classification of automobile fasteners is by function. The following are the most common varieties you need to know:

A nut is a small fastener for automobiles made of steel or aluminum alloy. It has a spiral cutting thread that passes through the center and is mounted on bolts on both sides. Nuts and bolts as well as washers can be combined in a complete set to fasten automotive components

Anti-theft nuts

An Anti-theft nut is a type of nut with a domed top that covers the threaded end of a bolt. It provides a finished appearance and helps protect the threads from damage or corrosion.

Connector Nut

A connector nut is cylindrical in shape and has internal threads. It is typically used to join two pieces of material together, providing a threaded connection for bolts or screws.

Flange Nuts

Flange nuts have a wide circular flange at one end, which provides a larger bearing surface and helps distribute the load more evenly.

An automotive bolt is a simple and indispensable fastener that is made of metals such as steel and aluminum alloy. The most common are long hexagonal bolts with hex heads. When used with nuts or washers, it is used to secure automotive components such as engine parts, instrument panels, and suspension arms. Several types of automotive bolts include:

Hex Flange Bolts

Hexagonal flange bolts have a flange (wide circular base) under the hexagonal head, and generally the bolt length is relatively long and the force is relatively large.

Carriage Bolts

The carriage bolt has a smooth, rounded head with a square or rounded shoulder directly underneath, and the shoulder position is usually grooved to increase friction and make the connection more secure.

Plow Bolts

Plow bolts have a flat, countersunk head that allows for a flush installation when used with a matching countersunk hole.

A screw is a fastener with perfectly tapered teeth that is used to connect parts of two objects. It is capable of cutting its own threads in the hole (self-tapping screws) or mating with threaded holes (machine screws) in the part. Unlike bolts, it doesn't require washers or nuts because the threads hold it in place and hold it in place. The following other screw types are used in the automotive industry:

Countersunk Head Screw

These screws have tapered flat head and Allen wrench positions, while many of the screws have relaxation paint.

Head Cap Screws

These screws feature a cylindrical head with a socket (hexagonal) drive. They are often used in applications where a high fastening force is required.

Self-tapping Screws

These screws have threads specially designed to create their own mating threads as they are driven into a pre-drilled or pre-punched hole.

Coach Screw

Also known as lag screws, these screws have a hexagonal head and a coarse thread.

Self-clinching fasteners are one-time and permanent fasteners applicable in joining automotive sheet parts. Self-clinching nuts offer strong resistance to twisting and pulling out. They are available in a variety of different shank lengths. Self-clinching nuts work well with metals, and in some situations, they can even be used with stainless steel panels. The variety of parts also includes nuts with thread-locking, closed parts, flush-on-both-sides nuts, and miniature designs.

A fastener with a head and tail at the opposing ends is called a rivet. It helps in permanent part assembly and mainly consists of steel or aluminum. There are numerous rivet types that can be used to attach two or more automotive components, including solid rivets, blind rivets, tube rivets, and split rivets.

They are automotive clips and fasteners having both automotive and non-automotive applications comprised of plastic or metal. They come in a variety of designs but provide simpler solutions. They can be used to place or hold different components, such as interior panels, door cards, or plastic bumpers (plastic), in the manufacture of automotive parts. There are reusable and non-reusable clip types.

It's crucial to select the proper kinds of automotive fasteners. In addition to selection, the fastener must be properly tightened to make it function well.

Tightening automotive fasteners ensures the safety and reliability of the car. Tightening fasteners to the specified torque values helps prevent parts from coming loose or falling off during operation, which can result in accidents or damage to the vehicle.

Proper tightening also helps maintain the vehicle's performance. Fasteners that are not tightened adequately can lead to vibrations, excessive noise, or even component failure. For example, loose bolts on engine components can result in oil leaks, loss of power, or even engine damage.

Ensuring proper tightening of fasteners helps prevent unnecessary wear and tear. Over-tightening can cause damage to the fasteners or the surrounding components while under-tightening can lead to increased stress and premature failure of the parts.

Selecting the proper type of auto fasteners is an important step. Companies that make automotive components require a trustworthy supplier of fasteners.

Need fasteners for automotive test products? Richconn can assist you in producing various automotive fasteners for prototypes or finished goods.

Richconn’s engineering team has several years of experience in auto fasteners manufacturing processes, including OEM CNC machining, and 3D printing services, and can respond to your questions or make design recommendations for your project. It produces automotive fasteners in both plastic and metal that are of high quality and precision, ensuring that a vehicle will operate as it should. Just send us your automotive fastener design and get an instant quote for free now!

Automotive fasteners are a vital component in joining two automotive parts together. As they have different properties, you need to choose the right type for your automotive projects. Do you have a question about manufacturing automotive fasteners? Whenever you need fasteners for CNC metal machining, kindly contact us.

How Are Tolerances in Machining Created?October 26, 2023Parts in the processing process, due to various reasons, processing and manufacturing of parts size can not be exactly the same as the size of the parts drawing design, the degree of deviation between the actual geometric parameters and the ideal geometric parameters for the parts processing error.view

How Are Tolerances in Machining Created?October 26, 2023Parts in the processing process, due to various reasons, processing and manufacturing of parts size can not be exactly the same as the size of the parts drawing design, the degree of deviation between the actual geometric parameters and the ideal geometric parameters for the parts processing error.view Exploring Nylon: A World of PossibilitiesSeptember 28, 2023Nylon's remarkable strength and versatility have made it a cornerstone of the textile industry. From silky stockings to rugged outdoor wear, nylon fibers have revolutionized our wardrobes.view

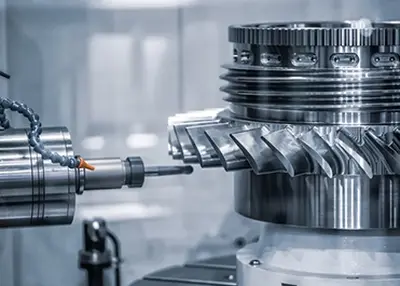

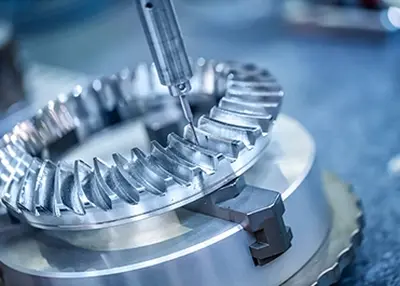

Exploring Nylon: A World of PossibilitiesSeptember 28, 2023Nylon's remarkable strength and versatility have made it a cornerstone of the textile industry. From silky stockings to rugged outdoor wear, nylon fibers have revolutionized our wardrobes.view How Many Types of Gears Are There? What Common Materials Are Suitable for Making Gears?October 26, 2023Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.view

How Many Types of Gears Are There? What Common Materials Are Suitable for Making Gears?October 26, 2023Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.view Sheet Metal Bending: Comprehensive Insights from Processes to EconomicsJuly 25, 2024Sheet metal bending holds a significant place in manufacturing. Let’s discover its diverse processes, unique methods, safety aspects, and cost analysis in this comprehensive exploration.view

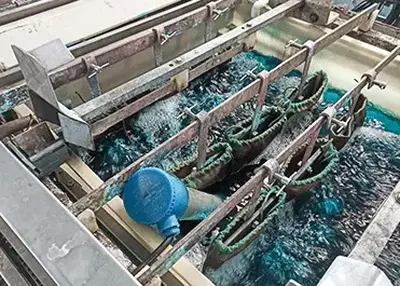

Sheet Metal Bending: Comprehensive Insights from Processes to EconomicsJuly 25, 2024Sheet metal bending holds a significant place in manufacturing. Let’s discover its diverse processes, unique methods, safety aspects, and cost analysis in this comprehensive exploration.view Cleaning Machined Parts: A Comprehensive Guide to Elevate CNC Machining QualityNovember 13, 2023Welcome to Richconn, where precision meets perfection in CNC machining. In the world of machining, ensuring the cleanliness of machined parts is not just a step; it's a commitment to excellence.view

Cleaning Machined Parts: A Comprehensive Guide to Elevate CNC Machining QualityNovember 13, 2023Welcome to Richconn, where precision meets perfection in CNC machining. In the world of machining, ensuring the cleanliness of machined parts is not just a step; it's a commitment to excellence.view Flexible CNC Lead Times - Save Money with Longer Lead TimesOctober 12, 2023From now on, you have the flexibility to choose your CNC delivery times and thus determine your own delivery dates and costs for your CNC parts. As part of the Flexible Manufacturing option, our lead times of 6 to 12 days offer you a lower price - and you'll still receive your parts faster than most other suppliers.view

Flexible CNC Lead Times - Save Money with Longer Lead TimesOctober 12, 2023From now on, you have the flexibility to choose your CNC delivery times and thus determine your own delivery dates and costs for your CNC parts. As part of the Flexible Manufacturing option, our lead times of 6 to 12 days offer you a lower price - and you'll still receive your parts faster than most other suppliers.view

EN

EN

ru

ru