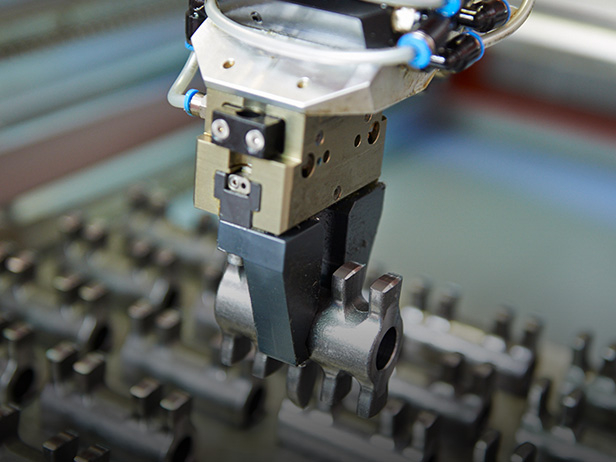

In today's fast-paced manufacturing world, the utilization of CNC (Computer Numerical Control) machines has become pivotal for businesses and hobbyists alike. These automated tools offer unparalleled precision and efficiency in various industries, from automotive to aerospace, and even the creation of intricate custom components. However, one question looms large for anyone considering CNC machining: What are the costs involved?

CNC machines have revolutionized the manufacturing landscape, automating processes, enhancing precision, and reducing the margin of error. This paradigm shift has created a surge in demand for CNC machining services. It's no wonder, given the remarkable results they deliver.

While CNC machines offer remarkable advantages, their costs can be a stumbling block for potential users. Here's where understanding CNC machine costs comes into play. Whether you're a manufacturer aiming to optimize your expenses or an individual enthusiast looking to embark on CNC machining projects, comprehending these costs is pivotal.

Table 1: The CNC Revolution

| Advantages of CNC Machines |

|---|

| Automation |

| Precision |

| Efficiency |

| Reduced Error Margin |

In the table above, we've outlined the primary advantages of CNC machines, which include automation, precision, efficiency, and a reduced margin of error. These advantages are at the core of why CNC machining is so sought after in various industries.

Table 2: The Crux of the Matter - Cost

| Significance of CNC Machine Costs |

|---|

| Budget Considerations |

| Informed Decision-Making |

| Cost Optimization |

| Alignment with Projects |

In Table 2, we highlight the significance of understanding CNC machine costs. This includes considering your budget, making informed decisions, optimizing costs, and aligning your machine choice with your specific projects.

Richconn: Your CNC Machining Partner

Before we delve into the factors that influence CNC machine costs and explore the various types of CNC machines available, it's worth noting that Richconn is a professional precision machine shop based in China. Richconn offers a wide range of CNC machining services, making them a valuable resource for your CNC needs.

The type of CNC machine you choose is a primary factor in determining the cost. Different machines are suited to different tasks. For example, a CNC milling machine is excellent for creating detailed three-dimensional components, while a CNC lathe excels at shaping cylindrical pieces. The complexity of your projects will guide you in selecting the appropriate machine.

Table 3: Machine Type and Complexity

| Machine Type | Typical Applications | Complexity |

|---|---|---|

| CNC Milling | Detailed 3D Components | High |

| CNC Lathe | Shaping Cylindrical Pieces | Moderate |

| CNC Router | Cutting and Engraving | Variable |

Table 3 provides an overview of different machine types, their typical applications, and the associated complexity level. Understanding this will help you select the right machine for your projects.

The size of the CNC machine and its working capacity are major cost determinants. Larger machines that can handle bigger materials or work on more substantial projects tend to be more expensive. It's important to choose a machine size that matches your project requirements, as investing in a machine with excessive capacity can unnecessarily inflate costs.

Table 4: Machine Size and Capacity

| Machine Size | Material Size | Work Capacity |

|---|---|---|

| Small CNC | Limited | Small to Medium |

| Medium CNC | Moderate | Medium to Large |

| Large CNC | Extensive | Large and Complex |

Table 4 outlines the correlation between machine size, material size, and work capacity, assisting you in making cost-effective choices.

Precision is a critical factor in CNC machining, particularly for industries such as aerospace and medical devices. The level of precision and tolerance required for your projects directly impacts costs. Tighter tolerances demand more advanced and precise machines, resulting in higher expenses.

Table 5: Precision and Tolerance Requirements

| Precision Level | Tolerance Requirements | Complexity |

|---|---|---|

| Low | Standard Tolerances | Moderate |

| Medium | Tighter Tolerances | High |

| High | Ultra-Tight Tolerances | Very High |

Table 5 categorizes precision levels, tolerance requirements, and complexity. This information will aid you in understanding the cost implications of precision in CNC machining.

The features and capabilities of a CNC machine can significantly affect costs. Advanced functionalities, such as multi-axis machining, automatic tool changers, and high-speed spindles, come at an added expense. Your choice should align with your specific project needs to avoid unnecessary costs.

Table 6: Additional Features and Functionality

| Feature | Function | Added Cost |

|---|---|---|

| Multi-Axis Machining | Complex Geometries | High |

| Automatic Tool Changer | Tool Versatility | Moderate |

| High-Speed Spindle | Increased Efficiency | Variable |

Table 6 helps you understand the cost implications of different additional features and functionalities commonly found in CNC machines.

CNC milling machines are a popular choice for creating intricate three-dimensional components. These machines employ rotating cutting tools to remove material from a workpiece. The cost of a CNC milling machine can vary based on several factors.

Table 7: CNC Milling Machine Costs

| Factor | Cost Influence |

|---|---|

| Machine Size | Moderate to High |

| Precision Requirements | Moderate to High |

| Additional Features | Variable |

Table 7 provides an overview of the factors that influence CNC milling machine costs. Machine size, precision requirements, and additional features play a key role in determining the overall cost.

The cost of a CNC milling machine can range from a few thousand dollars for a small, basic machine to several hundred thousand dollars for a large, high-precision machine with advanced features.

CNC lathe machines are ideal for shaping cylindrical pieces. They work by rotating the workpiece while a cutting tool moves along the length of the material. The cost of a CNC lathe machine is influenced by various factors.

Table 8: CNC Lathe Machine Costs

| Factor | Cost Influence |

|---|---|

| Machine Size | Moderate to High |

| Precision Requirements | Moderate to High |

| Additional Features | Variable |

Table 8 outlines the factors that impact CNC lathe machine costs, including machine size, precision requirements, and additional features.

The cost of a CNC lathe machine can vary widely. Small to medium-sized machines may cost between $20,000 and $100,000, while large, high-precision models can exceed $500,000.

CNC router machines are specialized for cutting, engraving, and shaping materials like wood, plastic, and composites. They are a cost-effective solution for projects with less complex geometries.

Table 9: CNC Router Machine Costs

| Factor | Cost Influence |

|---|---|

| Machine Size | Low to Moderate |

| Precision Requirements | Low to Moderate |

| Additional Features | Variable |

Table 9 presents the factors affecting CNC router machine costs, including machine size, precision requirements, and additional features.

The cost of a CNC router machine typically falls in the range of $5,000 to $50,000, depending on the size and features.

The price of CNC machines can vary significantly from one region to another. One of the key factors driving these variances is the demand and supply dynamics in the region. Regions with higher demand for CNC machines may experience higher prices due to increased competition among buyers.

Table 10: Regional Demand and Supply

| Region | Demand-Supply Impact | Cost Variance |

|---|---|---|

| Developed Countries | High Demand, High Supply | Moderate to High |

| Developing Countries | Growing Demand | Low to Moderate |

Table 10 illustrates the impact of regional demand and supply on CNC machine costs. Understanding this can help you navigate cost disparities effectively.

Currency exchange rates also play a pivotal role in CNC machine costs. Fluctuations in currency values can affect the cost of importing CNC machines. It's essential to stay updated on currency exchange rates when dealing with international suppliers.

Table 11: Currency Fluctuations

| Currency Impact | Cost Influence |

|---|---|

| Strong Currency | Lower Costs |

| Weak Currency | Higher Costs |

Table 11 outlines the cost influence of currency fluctuations. A strong local currency can result in lower costs, while a weak currency can lead to higher costs.

Government regulations regarding the import and export of CNC machines can also have a substantial impact on costs. Tariffs, taxes, and customs duties may vary from region to region, further affecting the final cost of the machine.

Table 12: Import and Export Regulations

| Regulatory Environment | Cost Influence |

|---|---|

| Low Barriers | Lower Costs |

| High Barriers | Higher Costs |

Table 12 highlights the influence of import and export regulations on CNC machine costs. Regions with low barriers often result in lower costs, while those with high barriers may lead to higher costs.

For those looking to explore cost-effective CNC machine solutions, sourcing from China can be a strategic move. Richconn, as a professional CNC machining service company based in China, offers high-quality CNC machines and cnc turning service at competitive prices. By leveraging China's manufacturing capabilities, you can potentially reduce your CNC machine costs significantly.

Before you can obtain an accurate cost estimate for a CNC machine, it's crucial to have a clear understanding of your project requirements. Define the materials you'll be working with, the complexity of your designs, and your precision and tolerance specifications.

Table 13: Project Requirement Considerations

| Project Aspect | Key Considerations |

|---|---|

| Materials | Type, Size, Quantity |

| Complexity | Geometric Complexity |

| Precision and Tolerance | Specific Requirements |

Table 13 helps you identify the key considerations for understanding your project requirements, a crucial first step in obtaining accurate cost estimates.

To get customized cost estimates for CNC machines, you'll need to reach out to suppliers and manufacturers. Provide them with detailed information about your project requirements. This includes the type of machine you're interested in, your material specifications, project complexity, and precision requirements.

For those looking to source CNC machines or machining services, Richconn, a prominent CNC machining service company based in China, can provide you with customized quotes. They offer a wide range of CNC machines, including milling machines, lathe machines, and more. By collaborating with Richconn, you can benefit from their expertise and cost-effective solutions.

Once you've received quotes from different suppliers and manufacturers, it's essential to compare them thoroughly. Pay attention not only to the price but also to the included features, warranty, and customer support. Be prepared to negotiate to get the best possible deal that aligns with your project requirements and budget.

CNC machine costs are not set in stone; they fluctuate with market trends. It's essential to stay informed about the latest developments in the CNC machine market. Key trends to watch out for include:

Advancements in Technology: The introduction of new technologies and innovations can impact machine costs. Keep an eye on the latest advancements in CNC technology.

Market Demand: Changes in market demand, particularly for specific types of CNC machines, can affect prices. High demand can lead to increased costs.

Economic Factors: Economic conditions, both global and regional, can influence machine costs. Economic downturns may lead to lower prices as manufacturers seek to boost sales.

Material Costs: The prices of raw materials used in CNC machine construction can fluctuate, impacting the overall cost.

To make the most of market trends, consider timing your CNC machine purchase strategically. While it's not always possible to predict market shifts, being aware of market conditions can help you make well-informed decisions.

Buy During Downturns: During economic downturns or when there is lower demand, you may find more competitive prices.

Seasonal Trends: Some industries have seasonal demand for CNC machines. Purchasing off-season may yield cost savings.

To navigate market trends effectively, stay informed through industry publications, online forums, and networking with professionals in the CNC machining field. Regularly updating your knowledge will help you seize opportunities when CNC machine prices are in your favor.

CNC machine cost information can be a valuable educational resource. Students, educators, and institutions can utilize this data for various purposes:

Curriculum Development: Educators can incorporate real-world cost data into their curricula, providing students with practical knowledge.

Student Projects: Students working on CNC-related projects can better understand budgeting and cost considerations.

Research and Case Studies: Educational institutions can conduct research and create case studies related to CNC machine costs and their implications in various industries.

Table 14: Educational Applications

| Application | Educational Benefit |

|---|---|

| Curriculum Development | Practical Knowledge for Students |

| Student Projects | Realistic Budgeting Experience |

| Research and Studies | Industry-Relevant Insights |

Table 14 highlights the educational benefits of leveraging CNC machine cost information.

In the realm of research, CNC machine cost information can be a valuable resource:

Feasibility Studies: Researchers can analyze cost data to assess the feasibility of projects involving CNC machines.

Cost Optimization: Understanding cost structures can lead to more cost-effective solutions in various industries.

Benchmarking: Researchers can use cost data to benchmark their projects against industry standards.

Table 15: Research and Development

| Application | Research and Development Benefits |

|---|---|

| Feasibility Studies | Informed Decision-Making |

| Cost Optimization | Efficiency and Cost Savings |

| Benchmarking | Industry Standards Comparison |

Table 15 outlines the benefits of using CNC machine cost information in research and development activities.

By leveraging CNC machine cost information for educational and research purposes, you can contribute to a deeper understanding of CNC machining and its implications across different domains.

Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view

Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view How to Produce High-quality Parts With CNC?June 25, 2024The passage mainly talks about the production progress of high-quality parts with the help of CNC. It’s strongly recommended that Richconn is an effective company, which owns many technicians and advanced technology.view

How to Produce High-quality Parts With CNC?June 25, 2024The passage mainly talks about the production progress of high-quality parts with the help of CNC. It’s strongly recommended that Richconn is an effective company, which owns many technicians and advanced technology.view What Is Mechanical Rack: Picking the Best for Your Custom PartsMay 22, 2024Delve into the world of equipment racks with this comprehensive article. Learn about their structure, design principles, materials, manufacturing processes, installation, commissioning, and more.view

What Is Mechanical Rack: Picking the Best for Your Custom PartsMay 22, 2024Delve into the world of equipment racks with this comprehensive article. Learn about their structure, design principles, materials, manufacturing processes, installation, commissioning, and more.view Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view

Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view A Look Into Plasma Cutting: How Does a Plasma Cutter Work?December 1, 2023It is an expert guide to plasma cutting. Keep reading and you get the answer to “how do plasma cutters work?”A Look Into Plasma Cutting: How Does a Plasma Cutter Work?Plasma cutting is a highly eff...view

A Look Into Plasma Cutting: How Does a Plasma Cutter Work?December 1, 2023It is an expert guide to plasma cutting. Keep reading and you get the answer to “how do plasma cutters work?”A Look Into Plasma Cutting: How Does a Plasma Cutter Work?Plasma cutting is a highly eff...view Why Motorcycle Parts Using CNC Machining?October 25, 2023Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.view

Why Motorcycle Parts Using CNC Machining?October 25, 2023Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.view