High carbon steel is a type of steel with a carbon content between 0.6% and 1.7%, which contains much more carbon than ordinary carbon steel, and is therefore also caled carbon tool steel. High carbon steel has high hardness, high strength, low toughness, and is easy to quench and temper, so it is widely used in the manufacture of machine parts, tools and blades that require high strength and hardness.

The higher the carbon content of high-carbon steel, the higher the hardness and strength, but the lower the toughness. The disadvantage of high carbon steel is that it is susceptible to fatigue cracking and requires frequent care and maintenance so as not to affect its service life. At the same time, high carbon steel is also more difficult to process, you need to use the appropriate processing methods and tools to ensure that the processing accuracy and surface quality.

High-carbon steel SK2, SK4, SK5, SK7 is mainly the difference in carbon content. s indicates Steel, K indicates the use of tools (such as knives and saws), the number is the beginning of the selected serial number. The new version of the Japanese standard has been changed to SKXX (XX indicates the carbon content).

Carbon (C): 0.90-1.04 percent

Silicon (Si): 0.35% or less

Manganese (Mn): 0.50-0.80 percent

Phosphorus (P): 0.030% or less

Sulfur (S): 0.030% or less

HIGH HARDNESS: SK2 steel has a higher carbon content, resulting in higher hardness, which makes it suitable for making tools and parts that require high hardness.

Good toughness: SK2 steel contains a certain amount of manganese, which can improve the toughness of the steel, making it strong and hard while having a certain degree of toughness and wear resistance.

Easy machining: SK2 steel has good machinability and is easy to perform machining operations such as cutting, drilling and milling.

Easy to quench and temper: SK2 steel has better quenching performance and tempering stability, the hardness and strength of the steel after quenching has been significantly improved.

POOR CORROSION RESISTANCE: SK2 steel has poor corrosion resistance and is susceptible to rust and corrosion, requiring anti-corrosion treatment.

SK2 steel is mainly used in the manufacture of cutting tools and cutters that require high hardness and wear resistance.

Carbon (C): 0.95-1.04 percent

Silicon (Si): 0.35% or less

Manganese (Mn): 0.50-0.80%

Phosphorus (P): 0.030% or less

Sulfur (S): 0.030% or less

HIGH HARDNESS: SK4 steel has a high carbon content, resulting in high hardness, which makes it suitable for making tools and parts that require high hardness.

Good toughness: SK4 steel contains a certain amount of manganese, which can improve the toughness of the steel, making it strong and hard while having a certain degree of toughness and wear resistance.

Easy machining: SK4 steel has good machinability and is easy to perform machining operations such as cutting, drilling and milling.

Easy to quench and temper: SK4 steel has good quenching properties and tempering stability, the hardness and strength of the steel after quenching has been significantly improved.

POOR CORROSION RESISTANCE: SK4 steel has poor corrosion resistance and is susceptible to rust and corrosion, requiring anti-corrosion treatment.

SK4 steel has high hardness and certain toughness, suitable for the manufacture of tools and parts that require high hardness and certain toughness.

Carbon (C): 0.80-0.90 percent

Silicon (Si): 0.35% or less

Manganese (Mn): 0.50-0.80 percent

Phosphorus (P): 0.030% or less

Sulfur (S): 0.030% or less

HIGH HARDNESS: SK5 steel has a high carbon content, resulting in high hardness, which makes it suitable for making tools and parts that require high hardness.

Good toughness: SK5 steel contains a certain amount of manganese, which can improve the toughness of the steel, making it strong and hard while having a certain degree of toughness and wear resistance.

Easy machining: SK5 steel has good machinability and is easy to perform machining operations such as cutting, drilling and milling.

Easy to quench and temper: SK5 steel has good quenching performance and tempering stability, the hardness and strength of the steel after quenching has been significantly improved.

POOR CORROSION RESISTANCE: SK5 steel has poor corrosion resistance and is susceptible to rust and corrosion, requiring anti-corrosion treatment.

SK5 steel has moderate hardness and good toughness, suitable for the manufacture of tools and parts that require a certain degree of hardness and a certain degree of toughness.

Carbon (C): 0.60-0.70 percent

Silicon (Si): 0.35% or less

Manganese (Mn): 0.50-0.80 percent

Phosphorus (P): 0.030% or less

Sulfur (S): 0.030% or less

HIGH HARDNESS: SK7 steel has a high carbon content, resulting in high hardness, making it suitable for making tools and parts that require high hardness.

Good toughness: SK7 steel contains a certain amount of manganese, which can improve the toughness of the steel, making it strong and hard while having a certain degree of toughness and wear resistance.

Easy machining: SK7 steel has good machinability and is easy to perform machining operations such as cutting, drilling and milling.

Easy to quench and temper: SK7 steel has good quenching performance and tempering stability, the hardness and strength of the steel after quenching has been significantly improved.

POOR CORROSION RESISTANCE: SK7 steel has poor corrosion resistance and is susceptible to rust and corrosion, requiring anti-corrosion treatment.

SK7 steel has high toughness and a certain degree of hardness, suitable for the manufacture of tools and parts that require high toughness and a certain degree of hardness.

Having summarized the properties of high carbon steels SK2, SK4, SK5 and SK7, we cannot but emphasize the importance of precision machining in the application of these materials. Precision machining is a critical step in ensuring that high carbon steel tools and parts meet their design requirements. In this area, Richconn is an outstanding precision machining company with years of experience and expertise in providing you with high quality steel precision CNC machining services.

Whether you need to manufacture cutting tools and parts with high hardness, or tools and parts with a balance of hardness and toughness, Richconn can provide precise machining services to suit your needs. They understand the properties of different high carbon steel types and how to employ the appropriate machining methods and tools to ensure optimum machining accuracy and surface quality.

So if you're looking for a trusted partner for your high carbon steel machining needs, consider contacting Richconn, who will provide you with a professional, efficient and reliable solution that will ensure the success of your project. No matter the size of your project, Richconn will be able to meet your requirements and provide you with exceptional machining services.

Alodine: A Versatile and Effective Coating for AluminumDecember 5, 2023Alodine is a trade name for a chromate conversion coating that protects aluminum and other metals from corrosion. A chromate conversion coating is a thin layer of chromium compounds that forms on the surface of a metal when it reacts with a chromate solution.view

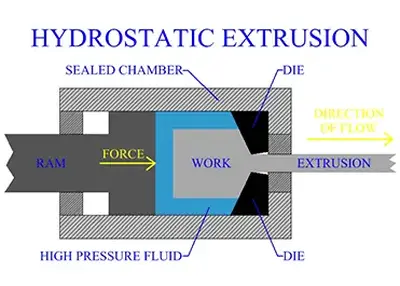

Alodine: A Versatile and Effective Coating for AluminumDecember 5, 2023Alodine is a trade name for a chromate conversion coating that protects aluminum and other metals from corrosion. A chromate conversion coating is a thin layer of chromium compounds that forms on the surface of a metal when it reacts with a chromate solution.view Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view Affordable 3D Printing Service: Tips for Cost-Effective SolutionsSeptember 1, 2023Whether you're an entrepreneur seeking rapid prototyping or a hobbyist looking to bring your creative ideas to life, 3D printing service offers a world of possibilities. However, have you ever tho...view

Affordable 3D Printing Service: Tips for Cost-Effective SolutionsSeptember 1, 2023Whether you're an entrepreneur seeking rapid prototyping or a hobbyist looking to bring your creative ideas to life, 3D printing service offers a world of possibilities. However, have you ever tho...view Excellent Corrosion Resistance of Stainless Steel-316L Stainless SteelOctober 24, 2023Dear viewers, today we are going to talk about an amazing material - 316L stainless steel. Did you know? This ordinary-looking material has amazing corrosion resistance! 316L stainless steel as a low carbon series of 316 steel, in addition to the same characteristics with 316 steel, its resistance to grain boundary corrosion is excellent, let's take a look at it!view

Excellent Corrosion Resistance of Stainless Steel-316L Stainless SteelOctober 24, 2023Dear viewers, today we are going to talk about an amazing material - 316L stainless steel. Did you know? This ordinary-looking material has amazing corrosion resistance! 316L stainless steel as a low carbon series of 316 steel, in addition to the same characteristics with 316 steel, its resistance to grain boundary corrosion is excellent, let's take a look at it!view Unveiling the World of Complex Machined Parts: A Comprehensive ExplorationNovember 14, 2023Embark on a journey into the intricate realm of complex machined parts, where precision meets innovation and engineering excellence takes center stage. In this comprehensive exploration, we'll delve into the definition, manufacturing processes, applications across industries, quality standards, material selection, market trends, and even the key players in the supply chain. Get ready to unlock the secrets behind these components that power the machinery shaping our modern world.view

Unveiling the World of Complex Machined Parts: A Comprehensive ExplorationNovember 14, 2023Embark on a journey into the intricate realm of complex machined parts, where precision meets innovation and engineering excellence takes center stage. In this comprehensive exploration, we'll delve into the definition, manufacturing processes, applications across industries, quality standards, material selection, market trends, and even the key players in the supply chain. Get ready to unlock the secrets behind these components that power the machinery shaping our modern world.view Inconel 718: A Superalloy with Lasting RelevanceOctober 12, 2023Metal 3D printing has finally catapulted Inconel, the classic nickel-based heat-resistant alloy, into the 21st century. Inconel 718, the hardened version of Inconel 625, is the latest addition to our growing range of metals for Direct Metal Laser Sintering (DMLS).view

Inconel 718: A Superalloy with Lasting RelevanceOctober 12, 2023Metal 3D printing has finally catapulted Inconel, the classic nickel-based heat-resistant alloy, into the 21st century. Inconel 718, the hardened version of Inconel 625, is the latest addition to our growing range of metals for Direct Metal Laser Sintering (DMLS).view

EN

EN

ru

ru