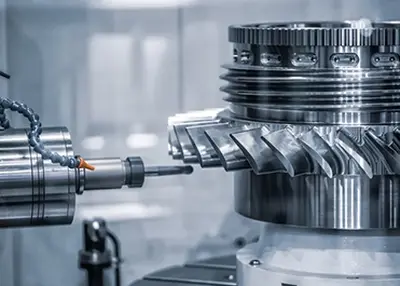

CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials. The materials employed in CNC milling operations wield immense influence over the quality, accuracy, and efficiency of the final products. In this comprehensive exploration, we will delve into the diverse features and characteristics of CNC milling materials, providing valuable insights to empower decision-making for your upcoming machining endeavors.

The realm of CNC milling is diverse, offering a spectrum of materials, each possessing unique properties. Common materials include aluminum, steel, stainless steel, brass, copper, and a variety of plastics such as ABS, acrylic, and nylon. The choice of material is pivotal, as it can significantly impact the project's success. Understanding the advantages and limitations of each material is crucial for making informed decisions aligned with the specific requirements of your project.

The features of CNC milling materials serve as key determinants in the machining process. Considerations such as hardness, strength, corrosion resistance, thermal conductivity, and machinability are paramount. For example, aluminum, prized for its lightweight nature and corrosion resistance, finds common use in aerospace and automotive applications. In contrast, stainless steel, lauded for its robust strength and durability, becomes the material of choice for applications necessitating superior mechanical properties.

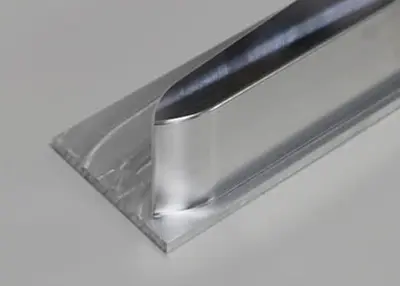

Beyond features, each material boasts specific characteristics that intricately impact the machining process. Some materials may exhibit a propensity to warp or distort during cutting, leading to inaccuracies in the final product. Others may generate excessive heat or produce chips that contribute to tool wear and influence surface finish. An astute consideration of these characteristics is vital when selecting materials for CNC milling to ensure the attainment of optimal results.

Choosing the right materials for CNC milling involves a meticulous examination of factors such as desired end-use properties, cost considerations, and material availability. Collaborating closely with your machining provider is essential to comprehending the intricacies of your project and selecting materials that seamlessly align with your goals. A judicious evaluation of the features and characteristics of CNC milling materials facilitates successful outcomes and ensures the realization of desired results in your machining projects.

In conclusion, the significance of CNC milling materials in the manufacturing process cannot be overstated. The selection of materials stands as a pivotal determinant influencing the quality and efficiency of the final products. By gaining a nuanced understanding of the features and characteristics inherent in different materials, informed decisions can be made, guiding the selection of materials for CNC milling projects. Whether the task involves machining aluminum, steel, or plastics, the careful consideration of material attributes is paramount to achieving optimal results in the CNC milling process.

As CNC technology continues to evolve, the landscape of available materials is likely to expand, offering new possibilities for innovation and precision in manufacturing. The world of CNC milling beckons with a diverse array of materials waiting to be harnessed, unlocking infinite potential for the realization of precise and innovative creations.

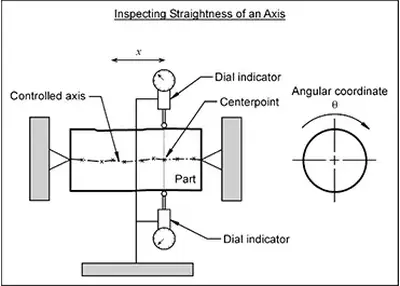

Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view

Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view Machining process of connecting rod partsNovember 16, 2023Connecting rod parts play a vital role in the mechanical field and are commonly used in engines, vehicle drivelines, industrial machinery and other applications. In order to ensure their accuracy, reliability and performance, the manufacture of connecting rod parts needs to go through several machining processes.view

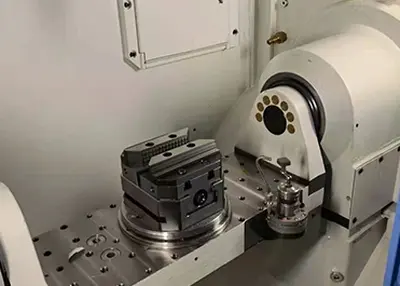

Machining process of connecting rod partsNovember 16, 2023Connecting rod parts play a vital role in the mechanical field and are commonly used in engines, vehicle drivelines, industrial machinery and other applications. In order to ensure their accuracy, reliability and performance, the manufacture of connecting rod parts needs to go through several machining processes.view What Products Can Be Customized with a Five Axis CNC Machining Center?August 14, 2023A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, mi...view

What Products Can Be Customized with a Five Axis CNC Machining Center?August 14, 2023A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, mi...view What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view

What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view Anodized Aluminum: How Much Do You Know?April 4, 2023Anodized aluminum refers to a layer of dense aluminum oxide plated on the surface of aluminum and aluminum alloy in order to prevent further oxidation, with chemical properties that are the same as th...view

Anodized Aluminum: How Much Do You Know?April 4, 2023Anodized aluminum refers to a layer of dense aluminum oxide plated on the surface of aluminum and aluminum alloy in order to prevent further oxidation, with chemical properties that are the same as th...view 7 Applications of CNC Machining Medical Parts ManufacturingOctober 25, 2023The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries.view

7 Applications of CNC Machining Medical Parts ManufacturingOctober 25, 2023The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries.view

EN

EN

ru

ru