Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains manganese, sulfur, phosphorus and other impurities of the multi-alloy. Sometimes in order to improve the mechanical properties or physical and chemical properties of cast iron, can also add a certain amount of alloying elements, get alloy cast iron.

According to the different forms of carbon in cast iron, cast iron can be divided into :

Carbon in addition to a few dissolved in the ferrite, the rest of the carbon in the form of carburized body in the cast iron, the fracture is silver-white, so called white cast iron. At present, white cast iron is mainly used as raw materials for steelmaking and production of malleable cast iron blanks.

Carbon all or most of the flake graphite present in the cast iron, the fracture is dark gray, so it is called gray cast iron.

Part of the carbon in the form of graphite, similar to gray cast iron; another part of the free carburization form, similar to white cast iron. Fracture in the black and white spots, so called pockmarked cast iron. This type of cast iron also has a large hard brittle, so the industry is also rarely used.

According to the different graphite forms in cast iron, cast iron can be divided into :

Gray cast iron graphite is flaky.

Graphite in cast iron is flocculent. It is from a certain composition of white cast iron by high temperature and long time after annealing. Its mechanical properties (especially toughness and plasticity) is higher than gray cast iron, so it is customarily called malleable cast iron.

The graphite in cast iron is spherical. It is in the iron casting by spheroidization treatment before obtaining. This kind of cast iron is not only mechanical properties than gray cast iron and malleable cast iron, production process than malleable cast iron is simple, but also through heat treatment to further improve its mechanical properties, so it is increasingly widely used in the production.

Cast iron is greater than 2.1% carbon iron and carbon alloy, it is the casting pig iron (part of the steelmaking pig iron) in the furnace to re-melt, and add into the ferroalloys, scrap steel, blast furnace iron to adjust the composition and get. Difference with pig iron is cast iron is a secondary process, mostly processed into cast iron parts. Cast iron has excellent casting can be made into complex parts, generally have good cutting and machining. In addition, it has good wear resistance and vibration damping, low price and other characteristics.

The cast iron grade indicated: (according to GB5612-85)

| Cast Iron Name | Designation | Representation Example |

| Gray Cast Iron | HT | HT100 |

| Malleable Cast Iron | RuT | RuT400 |

| Ductile Iron | QT | QT400-17 |

| Pearlitic Malleable Cast Iron | KHT | KHT300-06 |

| Whiteheart Malleable Cast Iron | KBT | KBT350-04 |

| Ferritic Malleable Cast Iron | KZT | KZT450-06 |

| Abrasion Resistant Cast Iron | MT | MT Cu1PTi-150 |

| Wear-Resistant White Cast Iron | KmBT | KmBTMn5Mo2Cu |

| Abrasion Resistant Ductile Cast Iron | KmQT | KmQTMn6 |

| Austenitic Cast Iron | AT | ---- |

Various cast iron code, by the cast iron characteristics of the Hanyu Pinyin letters of the first capitalized body letters. When two kinds of cast iron name code letters are the same, can be in the upper case body letters after the lower case body letters to distinguish. The same name cast iron, need to be subdivided, take its subdivided characteristics of the first capital letters of Hanyu Pinyin, arranged in the back.

Cast iron name, code and grade expression:

Note: A group of numbers after the designation in the grade indicates the value of tensile strength; when there are two groups of numbers, the first group indicates the value of tensile strength, and the second group indicates the value of elongation. Two groups of figures separated by "a".

Alloying elements with international element symbols, content greater than or equal to 1%, expressed in whole numbers: less than 1 % is generally not labeled. Conventional elements (C, Si, Mn, S, P) are generally not labeled, with a special role, before the labeling of its element symbols and content.

White cast iron in all the carbon to permeate the carbon (Fe3c) form, because the fracture is bright white. Therefore, it is called white cast iron, due to a large number of hard and brittle Fe3c, white cast iron hardness, brittle, difficult to process. Therefore, in the industrial application is rarely used directly, only for a few requirements of wear-resistant and not impact parts, such as wire drawing mold, ball mill iron ball. Mostly used as steel and malleable cast iron billet.

Most or all of the carbon in cast iron to free state flake graphite exists. The fracture is gray. It has good casting properties, good machinability, wear reduction, good wear resistance, plus it melts the ingredients are simple, low cost, widely used in the manufacture of complex structures and wear-resistant castings.

Gray cast iron according to the matrix organization, divided into ferrite-based gray cast iron, pearlite - ferrite-based gray cast iron and pearlite-based gray cast iron three categories.

Due to the presence of flake graphite within the gray cast iron, and graphite is a small density, low strength, low hardness, plasticity and toughness tend to zero component. Its presence as in the steel matrix on the existence of a large number of small gaps, that is, to reduce the bearing area, but also to increase the source of cracks, so gray cast iron low strength, poor toughness, can not be pressure machining. In order to improve its performance, before pouring in the iron water to add a little amount of ferrosilicon, calcium silicate and other inoculants, so that the pearlite matrix refinement.

Malleable cast iron is a low carbon, silicon content of iron and carbon alloy cast into white cast iron billet, and then after a long time of high temperature annealing treatment, so that the carburite decomposition of flocculent graphite and become, that is, malleable iron is a graphitization treatment of white cast iron.

Malleable cast iron according to heat treatment microstructure is divided into two categories; a class of black core malleable cast iron and pearl malleable cast iron. Black heart malleable iron organization is mainly ferrite (F) basic + flocculated graphite; pearlitic malleable iron organization is mainly pearlite (P) matrix + flocculated graphite. Another type is white heart malleable cast iron, white heart malleable cast iron organization is determined by the section size, small section of ferrite as the matrix, large section of the surface area of ferrite, pearlite and annealed carbon in the heart.

Graphite becomes fine and uniformly distributed, after this gestation treatment of cast iron. Known as pregnant cast iron.

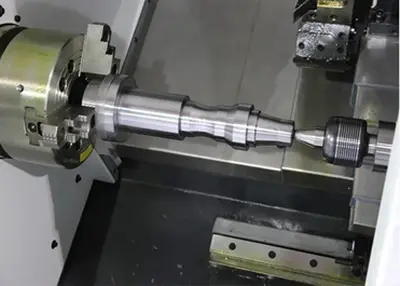

In the iron (ductile pig iron) pouring before adding a certain amount of spheroidizing agent (commonly used ferrosilicon, magnesium, etc.) to make the graphite in the cast iron spheroidization. As carbon (graphite) in spherical form in the cast iron matrix, improve its role in the matrix of the cut, ductile iron tensile strength, yield strength, plasticity, impact toughness greatly improved. And has the advantages of wear-resistant, shock absorption, good process performance, low cost, etc., is now widely used as a substitute for malleable cast iron and part of the cast steel, forged steel parts, such as crankshafts, connecting rods, rollers, automobile rear axle.

Cast iron is an important iron-carbon alloy, and its different types have unique applications in industry and manufacturing. White cast iron is suitable for specific wear-resistant fabrications, while gray cast iron is widely used in the manufacture of complex structures and wear-resistant parts due to its excellent castability and machinability. Malleable cast iron improves its performance through graphitization, while ductile cast iron excels in tensile strength, yield strength, plasticity and impact toughness, and has replaced some cast and forged steel parts.

If you are in need of precision CNC machining services, consider contacting Richconn, a precision machine shop that specializes in providing high-quality CNC machining services to meet the needs of a variety of industries. Whether you need customized cast iron parts or other precision parts, Richconn has the experience and technology to meet your needs. Let Richconn be your reliable partner in helping you achieve your manufacturing goals.

Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view

Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view Application of 5-Axis Machining Center in High-Speed Blower Impeller ManufacturingMarch 24, 2023With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture ...view

Application of 5-Axis Machining Center in High-Speed Blower Impeller ManufacturingMarch 24, 2023With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture ...view Unlocking Precision: A Comprehensive Guide to Machining KeywaysNovember 15, 2023Welcome to the definitive guide on keyway machining, where precision meets performance. In this in-depth exploration, we will unravel the complexities of keyway machining, providing you with practical insights, expert tips, and real-world applications. Whether you're an engineer seeking mastery or an enthusiast eager to delve into the intricacies, this guide promises a thorough journey through the world of keyway machining.view

Unlocking Precision: A Comprehensive Guide to Machining KeywaysNovember 15, 2023Welcome to the definitive guide on keyway machining, where precision meets performance. In this in-depth exploration, we will unravel the complexities of keyway machining, providing you with practical insights, expert tips, and real-world applications. Whether you're an engineer seeking mastery or an enthusiast eager to delve into the intricacies, this guide promises a thorough journey through the world of keyway machining.view 18-8 Stainless Steel vs 304: What's the Difference and Which One to Choose?December 7, 2023Stainless steel is one of the most widely used materials in the world, thanks to its excellent properties, such as corrosion resistance, strength, durability, and aesthetics. However, not all stainless steel grades are the same.view

18-8 Stainless Steel vs 304: What's the Difference and Which One to Choose?December 7, 2023Stainless steel is one of the most widely used materials in the world, thanks to its excellent properties, such as corrosion resistance, strength, durability, and aesthetics. However, not all stainless steel grades are the same.view Narrowing Down Material Options For CNC Machining.October 17, 2023Choice is good. In most cases, the greater the selection, the greater the chance of finding just the right thing. But a large selection also means that finding the perfect material becomes more complicated.view

Narrowing Down Material Options For CNC Machining.October 17, 2023Choice is good. In most cases, the greater the selection, the greater the chance of finding just the right thing. But a large selection also means that finding the perfect material becomes more complicated.view Aero-engine Why the Whole Leaf DiskOctober 23, 2023Aero-engine is the heart of the aircraft, also known as the pearl in the crown of industry, the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields.view

Aero-engine Why the Whole Leaf DiskOctober 23, 2023Aero-engine is the heart of the aircraft, also known as the pearl in the crown of industry, the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields.view

EN

EN

ru

ru