Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.

CNC machining is the cornerstone of modern manufacturing. It's a technology that drives precision, efficiency, and repeatability. But what exactly is CNC machining?

CNC machining, or Computer Numerical Control machining, is a process where computer programs control the movement and operation of machinery and tools to shape, cut, and create intricate parts from various materials. Whether you're a budding engineer, a business owner, or just someone curious about how things are made, understanding the basics of CNC machining is essential.

CNC machining is a technology-driven manufacturing process that ensures precision and repeatability. It's the backbone of modern manufacturing.

CNC machining comes in various flavors, each suited to different applications. Let's dive into the types of CNC machining.

Milling: Milling machines use rotary cutters to remove material from a workpiece, creating custom shapes and designs.

Turning: Turning machines rotate the workpiece while cutting tools shape it. This process is ideal for cylindrical parts.

Drilling: Drilling machines create holes in workpieces with precision and accuracy.

EDM (Electrical Discharge Machining): EDM uses electrical discharges to shape materials, often for intricate and complex parts.

Table 1: Types of CNC Machining

| CNC Machining Type | Description |

|---|---|

| Milling | Rotary cutters remove material to create custom shapes. |

| Turning | Workpiece rotates while cutting tools shape it, ideal for cylindrical parts. |

| Drilling | Precision hole creation in workpieces. |

| EDM (Electrical Discharge Machining) | Uses electrical discharges for intricate and complex parts. |

Different types of CNC machining suit various manufacturing needs, allowing for versatility and precision in the production process.

Why should you choose CNC machining over traditional manufacturing methods? Let me highlight some key advantages for you.

Precision: CNC machining offers unrivaled precision, ensuring that every part is made to exact specifications.

Efficiency: With automation and computer control, CNC machining is incredibly efficient, reducing production time.

Consistency: CNC machining produces consistent results, reducing errors and waste.

Complexity: CNC machining can create intricate and complex parts that are impossible with manual methods.

Table 2: Advantages of CNC Machining

| Advantages | Description |

|---|---|

| Precision | CNC machining offers precision to exact specifications. |

| Efficiency | Automation and computer control reduce production time. |

| Consistency | Consistent results reduce errors and waste. |

| Complexity | Intricate and complex parts are achievable with CNC machining. |

CNC machining offers precision, efficiency, and consistency, making it the preferred choice for modern manufacturing.

Now, let's explore Richconn's CNC machining services, which are designed to meet a wide range of manufacturing needs.

Richconn offers precision turning services that cater to a variety of industries. Our CNC turning services include the machining of cylindrical components, such as shafts, pins, and couplings. We utilize state-of-the-art CNC turning equipment to deliver parts with tight tolerances and exceptional surface finishes. Whether you require a single prototype or high-volume production, our turning services are tailored to your specifications.

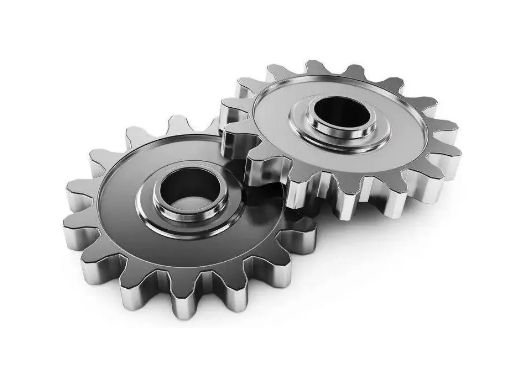

In addition to turning, Richconn provides top-notch CNC milling services. Our CNC milling capabilities enable us to manufacture complex parts with precision and efficiency. We can handle a wide range of materials, including metals and plastics, to produce components like brackets, housings, and gears. With a commitment to quality and a team of skilled machinists, Richconn's milling services ensure that your project's needs are met.

Table 3: Richconn's CNC Machining Services

| Service Type | Description |

|---|---|

| Turning Services | Precision turning for cylindrical components with tight tolerances. |

| Milling Services | CNC milling for the production of complex parts from various materials. |

Richconn offers both turning and milling services, ensuring that your specific manufacturing needs are met with precision and efficiency. Whether you need cylindrical components or complex parts, our team is dedicated to delivering top-quality results.

Now, let's shift our focus to engineered machined products. These specialized parts play a crucial role in numerous industries.

Engineered machined products are custom components created through CNC machining to meet precise specifications. These parts are essential in various applications across industries such as aerospace, automotive, medical, and more.

Table 4: Common Applications of Engineered Machined Products

| Industry | Applications |

|---|---|

| Aerospace | Aircraft components, engine parts |

| Automotive | Transmission components, suspension parts |

| Medical | Surgical instruments, implant components |

| Electronics | Connectors, heatsinks, enclosures |

Engineered machined products come in various types, each designed for specific purposes.

Table 5: Common Types of Engineered Machined Products

| Type | Description |

|---|---|

| Gears | Used in power transmission, providing precise motion. |

| Shafts | Transmit torque and rotation in machines. |

| Brackets | Support and secure components within a system. |

| Housings | Enclosures for electronic components. |

Engineered machined products play a vital role in modern industrial applications, ensuring performance, reliability, and safety.

Engineered machined products represent the pinnacle of precision and quality in manufacturing. These custom components are created through CNC machining, a process known for its exceptional accuracy and efficiency. Let's delve deeper into the manufacturing excellence of engineered machined products.

The production of engineered machined products begins with detailed design and programming. Skilled engineers use advanced CAD/CAM software to create precise instructions for CNC machines. These instructions include specifications for materials, dimensions, and tolerances.

Once the programming is complete, CNC machines take over. These machines precisely shape and cut materials, adhering to the programmed instructions. This level of automation ensures consistent results, even for highly complex components.

Engineered machined products are crafted from a wide range of materials, including metals like aluminum, steel, and titanium, as well as various plastics. The choice of material depends on the specific application and the required properties, such as strength, heat resistance, or electrical conductivity.

The precision achieved during CNC machining is remarkable. Tolerances can be as tight as a few microns, ensuring that every part meets exact specifications. This level of accuracy is crucial for industries where safety and performance are paramount.

Engineered machined products find their place in a variety of industries due to their precision and reliability. Here are some notable applications:

Aerospace: Engineered machined products are used in aircraft components, including critical parts like engine components and landing gear.

Automotive: In the automotive sector, these components find applications in transmission systems, suspension parts, and engine components.

Medical: Surgical instruments, implant components, and diagnostic equipment rely on the precision of engineered machined products to ensure patient safety and health.

Electronics: Connectors, heatsinks, enclosures, and other electronic components benefit from the precision machining that ensures optimal performance and durability.

Richconn, with its years of experience and commitment to excellence, stands as a reliable partner for your engineered machined product needs. Our skilled team, state-of-the-art equipment, and dedication to quality ensure that your projects are in safe hands.

Whether you require custom gears for a cutting-edge aerospace project, precision shafts for automotive applications, or intricate brackets for electronics, Richconn has the expertise and capabilities to deliver top-quality engineered machined products.

Richconn takes pride in its commitment to delivering high-quality CNC machining and engineered machined products. Our dedication to precision and excellence ensures that your projects are completed with the utmost care and attention to detail. Here's how we ensure quality:

Richconn utilizes state-of-the-art CNC machines and equipment. These machines are regularly maintained and calibrated to guarantee consistent and precise results. We invest in the latest technology to stay at the forefront of the industry.

Our team of machinists and engineers are highly skilled and experienced. They understand the intricacies of CNC machining and work with dedication to meet your exact specifications. Their expertise is what makes Richconn a trusted partner for manufacturing needs.

Quality control is at the core of our operations. We have strict quality assurance protocols in place to inspect and verify every component we produce. This meticulous approach ensures that each part meets the highest standards of precision and reliability.

At Richconn, we understand that each project is unique. We offer customization options to tailor our services to your specific needs. Whether you require small quantities of complex parts or large volumes of standard components, we have the flexibility to accommodate your requirements.

Quality assurance is not just a part of our process; it's our guiding principle. Ensuring the quality of manufactured components is paramount for several reasons:

In industries like aerospace and medical, where human lives are at stake, there is no room for error. High-quality components ensure safety and reliability, preventing catastrophic failures.

Quality components translate into top-notch performance. Whether it's the smooth operation of machinery, efficient energy transmission, or the durability of products, quality plays a pivotal role.

Quality assurance minimizes defects and waste, reducing costs in the long run. It also means fewer recalls and replacements, saving both time and money.

In the world of CNC machining and engineered machined products, there are common challenges that both manufacturers and customers may encounter. Understanding these challenges and having effective solutions in place is essential for a successful partnership. Let's explore some of the common issues and how to address them:

Challenge: Complex component designs can be challenging to manufacture, often requiring intricate toolpaths and setups.

Solution: Collaboration between designers and manufacturers is key. Using advanced CAD/CAM software, Richconn's engineering team can work closely with you to simplify designs while maintaining functionality and precision.

Challenge: Choosing the right material is crucial for the performance and longevity of components.

Solution: Richconn provides material expertise, helping customers select the most suitable materials for their projects based on requirements such as strength, heat resistance, and conductivity.

Challenge: Achieving tight tolerances can be difficult, particularly in high-precision industries.

Solution: Richconn's CNC machines are equipped to handle the most demanding tolerances, ensuring precision and reliability.

Challenge: Ensuring consistent quality across large production runs is essential.

Solution: Richconn employs rigorous quality control procedures, including inspections and testing, to maintain the highest standards of quality and reliability.

Challenge: Balancing cost-effectiveness with high-quality production can be challenging.

Solution: Richconn's customization options and efficient processes help customers find cost-effective solutions without compromising quality.

Challenge: Meeting project deadlines can be a concern in a competitive market.

Solution: Richconn is committed to on-time delivery and can work with customers to meet their project timelines.

Challenge: Sustainable manufacturing is a growing concern in the industry.

Solution: Richconn continually assesses and improves its manufacturing processes to minimize environmental impact.

By addressing these common challenges with effective solutions, Richconn ensures that your projects are successful and meet the highest standards of precision and quality.

Selecting the right manufacturing partner is a critical decision that can significantly impact the success of your projects. Here are some key factors to consider when choosing a partner for CNC machining and engineered machined products:

Look for a machining manufacturer with a proven track record and extensive experience in CNC machining. Richconn, with its years of experience and skilled team, can be your trusted partner for precision components.

The quality of machinery and technology at a manufacturer's disposal plays a crucial role in the precision and efficiency of production. Richconn invests in cutting-edge CNC machines to ensure your components are manufactured with the utmost accuracy.

Your manufacturing partner should offer customization options to tailor their services to your specific project requirements. Richconn is committed to providing customized solutions for your unique needs.

Quality should be a non-negotiable aspect of manufacturing. Ensure that your partner has stringent quality control procedures in place. Richconn's dedication to quality assurance ensures that every component meets the highest standards.

Balancing cost-effectiveness with high-quality production is crucial. Richconn's efficient processes help you find cost-effective solutions without compromising quality.

Meeting project deadlines is essential. Your partner should be committed to on-time delivery. Richconn can work with you to ensure your project timelines are met.

In an era of increasing environmental awareness, consider a partner's commitment to sustainable manufacturing. Richconn continually assesses and improves its processes to minimize environmental impact.

A strong working relationship with your manufacturing partner is essential. Effective communication and collaboration are key to project success. Richconn's team is ready to collaborate with you at every stage of your project.

In the world of modern manufacturing, CNC machining and engineered machined products are essential for precision, reliability, and innovation. Richconn, with its state-of-the-art equipment, skilled workforce, and unwavering commitment to quality, is your ideal partner for meeting manufacturing needs.

If you're in search of custom components with unmatched precision and reliability, look no further. Richconn is here to bring your vision to life and deliver the highest quality engineered machined products.

Choose Richconn as your manufacturing partner and embark on a journey to manufacturing excellence. Contact us today to discuss your specific project requirements. Your success is our top priority, and we are ready to help you achieve it.

Electrophoresis Plating in Corrosion ResistanceJanuary 5, 2024When it comes to protecting metal objects from corrosion, electrophoresis plating is a game-changer. This process not only enhances the appearance of the metal but also provides a robust shield agains...view

Electrophoresis Plating in Corrosion ResistanceJanuary 5, 2024When it comes to protecting metal objects from corrosion, electrophoresis plating is a game-changer. This process not only enhances the appearance of the metal but also provides a robust shield agains...view How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view

How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view Cutting Costs, Not Quality: Exploring the Best Cheap CNC Material OptionsDecember 4, 2023In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the mos...view

Cutting Costs, Not Quality: Exploring the Best Cheap CNC Material OptionsDecember 4, 2023In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the mos...view 4 Axis CNC Machining: The Definitive Guide 2023August 29, 2023CNC machining is a widely used manufacturing process that involves the use of computer-controlled machines to create precise and complex parts from various materials. CNC machines can operate on diffe...view

4 Axis CNC Machining: The Definitive Guide 2023August 29, 2023CNC machining is a widely used manufacturing process that involves the use of computer-controlled machines to create precise and complex parts from various materials. CNC machines can operate on diffe...view Machined Bearings Basics and Working PrinciplesNovember 9, 2023Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.view

Machined Bearings Basics and Working PrinciplesNovember 9, 2023Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.view Resin Materials: What They Are, How They Differ, and How to Use ThemDecember 8, 2023Resin materials are synthetic or natural substances that can be molded or shaped into various forms. They are widely used in many industries and applications, such as art, crafts, jewelry, furniture, electronics, medical, aerospace, etc.view

Resin Materials: What They Are, How They Differ, and How to Use ThemDecember 8, 2023Resin materials are synthetic or natural substances that can be molded or shaped into various forms. They are widely used in many industries and applications, such as art, crafts, jewelry, furniture, electronics, medical, aerospace, etc.view