As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction. We’ve put together some of the important aspects you should know before investing in equipment and facilities.

It’s no secret that you need to produce your products as cost-effectively as possible to maximize sales and profits. Your research shows there is a market for your product. But that alone doesn’t guarantee your company’s success.

In addition to the product itself, you also need to know how to make it from the beginning. For example, not every part that can be produced as a prototype using 3D printing services can be produced in high volumes using injection molding.

However, even if you can use the methods discussed, you should ask yourself whether this design can be produced at a price that allows you to make the profit you need. Can the customer's design be adapted to produce the product more cheaply without sacrificing functionality or quality?

As a startup, you may not have the expertise to know the answers to these questions. In the long run you will need this expertise, but in the short term you can usually find it elsewhere. For example, you could hire a non-executive director or ask about supply chain.

If you find rapid prototyping companies that also produce end products using the manufacturing techniques you're considering, they can help you avoid pitfalls you might not realize until it's too late. By considering final manufacturing early in the development phase, the chances of getting the right results are increased when making a significant investment – while choosing the most cost-effective approach.

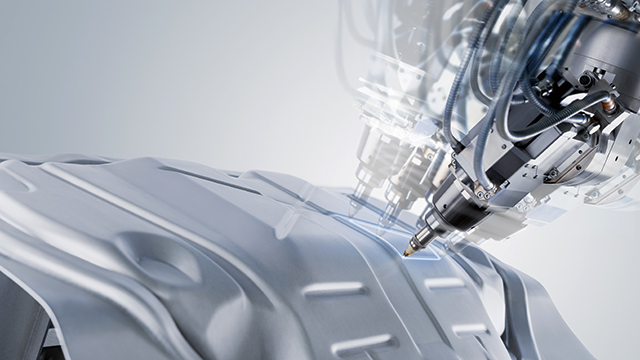

At Richconn, it all starts when you upload your CAD model to our digital manufacturing platform. You will receive a quote along with a feasibility study. If the design is not manufacturable, we recommend necessary modification steps, as well as steps to simplify the manufacturing process.

After you upload your design and receive feasibility feedback, you can discuss the details with one of our application engineers. This is important because automation is not a panacea. Sometimes you need professional advice to move forward. Because algorithms can only determine whether a design can be implemented. Usually only someone with enough experience can tell whether it is the best or most cost-effective variant to produce.

So before you make a big investment in equipment and facilities, you should know the answers to these questions.

Many companies fail not because of their ideas, but because the initial costs are too high. This means that expansion needs to be carefully considered and planned before investing a lot of money. Most startups need access to more financing options at this stage of their business. The good news is that once you prove your idea, there will be many companies and individuals willing to invest in your business.

You may not have all the answers, but having realistic sales projections of future cash flow is an invaluable advantage. The amount of investment is also measured in this way. At this stage, tact is required because if you hesitate for too long, competitors may capture important market share. But there’s no point in rushing, because after all, your production line needs to keep running and realize a timely return on investment.

Fortunately, today's digital manufacturing provides ample scope.

An option that is not always obvious is to outsource your own production entirely or cover bottlenecks in the early stages. In the modern digital world, you can easily control outsourced production from your laptop.

For example, you could invest in the core elements of a production line but outsource some components to limit initial capital expenditures. For example, through our online platform you can control all process steps from design to production and quality control right up to the desired dispatch date.

Or you may need to generate revenue and manufacture while waiting for critical factory components or CNC machined parts to be delivered. In this case, contract manufacturing can fill the gap.

You can also take advantage of on-demand production if you want to produce a pilot series for a small market in order to analyze future demand before deciding on the investment required for your own production line. If you need investor participation, this information will definitely help you strengthen your thesis.

Expanding business activities is a major challenge for every new company, but manufacturing companies especially cannot make any mistakes at this stage, since high investments in equipment and systems determine the future of the company.

Fortunately, in the digital age, you can always access relevant expertise, for example in supply chains, to benefit from qualifications that don’t (yet) exist for your own company. In today’s digital age, even product development and early manufacturing can be outsourced to reduce risk and capital expenditure.

Application of 5-Axis Machining Center in High-Speed Blower Impeller ManufacturingMarch 24, 2023With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture ...view

Application of 5-Axis Machining Center in High-Speed Blower Impeller ManufacturingMarch 24, 2023With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture ...view Carbon Steel vs Cast Iron: Which Is Better for CNC Machining?November 24, 2023Carbon steel and cast iron are two common types of metal materials that are used for CNC machining. They are both composed of iron and carbon, but they have different amounts of carbon and different structures.view

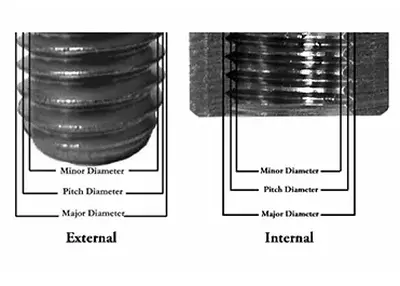

Carbon Steel vs Cast Iron: Which Is Better for CNC Machining?November 24, 2023Carbon steel and cast iron are two common types of metal materials that are used for CNC machining. They are both composed of iron and carbon, but they have different amounts of carbon and different structures.view UNF Threads vs UNC Threads and What Are UNF Threads and UNC ThreadsNovember 17, 2023In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.view

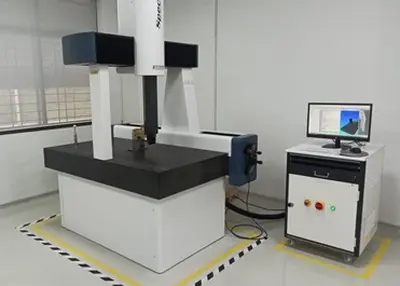

UNF Threads vs UNC Threads and What Are UNF Threads and UNC ThreadsNovember 17, 2023In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.view What Is a CMM Machine: Components, Uses, and BenefitsMarch 15, 2024Here is a thorough introduction to CMM machines from components, uses to benefits. Let’s have a deeper look and choose the best CMM service for your projects.view

What Is a CMM Machine: Components, Uses, and BenefitsMarch 15, 2024Here is a thorough introduction to CMM machines from components, uses to benefits. Let’s have a deeper look and choose the best CMM service for your projects.view Types of Casting | Which One Is Right for Your Project?December 7, 2023Compare the different types of casting, from sand casting to die casting. Learn about applications and safety measures. Choose the right casting solution!view

Types of Casting | Which One Is Right for Your Project?December 7, 2023Compare the different types of casting, from sand casting to die casting. Learn about applications and safety measures. Choose the right casting solution!view Shenzhen International Industrial Automation and Robot Exhibition 2023August 14, 2023The SIA 2023 Shenzhen International Industrial Automation and Robot Exhibition will be grandly held at the Shenzhen Convention and Exhibition Center from December 1-3, 2023. The exhibition covers indu...view

Shenzhen International Industrial Automation and Robot Exhibition 2023August 14, 2023The SIA 2023 Shenzhen International Industrial Automation and Robot Exhibition will be grandly held at the Shenzhen Convention and Exhibition Center from December 1-3, 2023. The exhibition covers indu...view

EN

EN

ru

ru