Steel is a metal alloy composed of iron and carbon, and it is the most prevalent metal alloy utilized in contemporary society. Its applications are so vast that practically all industries employ steel in one form or another. Apart from being one of the most ubiquitous metals, steel materials are also one of the most versatile in contemporary use. In this steel guide, we will delve into some of these attributes. Additionally, we will contemplate the diverse grades and applications of steel, as well as the considerations to bear in mind when selecting the appropriate type of steel for custom part prototyping and manufacturing. What makes steel stand out among other metals is its unique combination of strength, durability, and versatility."

The following is about what are the properties of steel. We're going to look at it both physically and chemically to analyze the material properties of steel.

Steel has a remarkably high melting point, approximately 1510°C. That is significantly higher even when compared to other metals. To further emphasize this, consider the melting points of bronze and copper, which are 1040°C and 1083°C, respectively. Steel is also an extremely dense metal, with a density of 7850kg/m3, approximately eight times that of water.

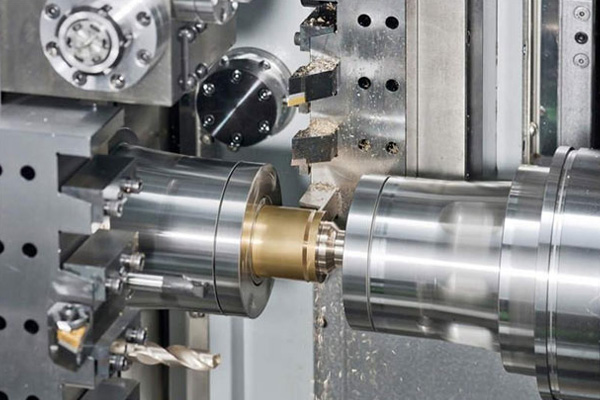

Let’s discuss steel strength. Steel is harder than iron. Hardness is typically a crucial factor in many CNC machined components. If a metal is too hard, its machinability will be compromised, making it challenging to work with. However, some metals need to be exceptionally hard due to their intended applications, such as in CNC cutting tools. Iron is far more brittle than steel. In industrial settings, many materials need to undergo elongation or stretching before they can be put to use. A brittle material is prone to breaking apart when it is elongated.

Once again, the grade of steel plays a crucial role in determining its elongation properties while steel thickness functions in determining its mechanical properties and suitability for various applications. Low-carbon steel can be stretched or elongated to a greater extent compared to high-carbon steel. The physical and chemical properties of steel ultimately dictate its applications and uses.

When it comes to what is steel made out of, carbon is usually mentioned. Steel is an alloy composed of iron and carbon. The carbon content in steel typically does not exceed 1.5%, indicating that the majority of steel is composed of iron. Apart from carbon, there are other metals that can be found within steel. Some of these metals, such as manganese and phosphorus, are intentionally added to target and enhance specific properties. Other metals present in steel are only incidentally present and are referred to as trace or residual elements. Examples of residual elements include silicon, copper, nickel, tin, and molybdenum.

Although iron constitutes the majority of the steel alloy, the other metals it contains can have a substantial impact on its properties. For instance, iron itself is relatively soft and has limited industrial application as an engineering material. The addition of carbon helps to strengthen and harden steel, making it far more valuable as an engineering material.

Pros:

1. Steel is an incredibly versatile material, with a wide range of grades and properties to meet various manufacturing demands and requirements.

2. It boasts exceptional resistance to corrosion, ensuring durability and longevity in diverse applications.

3. Steel is lightweight compared to many alternative materials, facilitating ease of handling and transportation.

4. Its excellent durability makes it a preferred choice for long-term use in industrial components, machinery, and infrastructure.

5. Steel is fully recyclable, making it an environmentally friendly option for sustainable manufacturing practices.

Cons:

1. Depending on the specific grade and treatment, steel can become brittle under certain conditions, which may lead to structural failures.

2. Some grades of steel are not easily heat-treatable, limiting their suitability for applications requiring specific mechanical properties.

3. While steel is generally resistant to corrosion, certain environmental factors or aggressive chemical exposures can still lead to degradation over time.

4. The production process for steel can be energy-intensive and may contribute to environmental pollution if not managed properly.

5. Higher grades of steel can be costly, potentially posing budget constraints for projects with tight financial considerations.

Most alloys share a common characteristic: the presence of different grades. This is because alloys are mixtures of more than one element, and varying the composition of the individual components can affect their properties. The elements of steel also affect the uses.

For steel, there are over 3,500 grades. However, all types of steel can be grouped into four broad categories: carbon, alloy, stainless, and tool steel. This grading system is based on the chemical composition of steel. Steel made of suitable ingredients is widely used. The variations in chemical composition are largely responsible for many of the observed variations in the physical properties of the different grades. As a result, this affects how they are used in rapid prototyping and custom parts manufacturing. There is a brief show of these grades.

1. Stainless Steel

Stainless steel is a highly relevant grade of steel in CNC machining, as well as in many household items. The name "stainless" comes from its high resistance to corrosion and many other chemical reactions. CNC stainless steel generally contains high amounts of chromium, up to 20%, and nickel. Its resistance to corrosion is about 200 times higher than that of mild steel, which makes it widely used in steel CNC machining. Stainless steel is also resistant to oxidation, thanks to the formation of a chromium film on its surface.

In addition to corrosion resistance, stainless steel has good formability and high tensile strength. Stainless steel can be classified into three types based on its crystalline structure: austenitic, ferritic, and martensitic. Each type has its unique properties and applications in different industries.

Austenitic

Austenitic stainless steel is a type of stainless steel that is rich in chromium and nickel. The steel composition typically includes about 18% chromium and 8% nickel, with a minimal carbon content of around 0.8%. While austenitic stainless steel has excellent corrosion resistance, it is not very heat-treatable and is also non-magnetic. Industrially, austenitic stainless steel is essential in manufacturing pump shafts, sheathing, and many components like screws and bolts. Additionally, this type of stainless steel is commonly used in household equipment.

Ferritic

Ferritic stainless steel is a type of stainless steel that contains between 12% and 18% chromium, trace amounts of nickel, and about 0.1% carbon. Other alloying elements, such as titanium, molybdenum, and aluminum, may also be present. Ferritic stainless steel has excellent corrosion resistance properties, making it suitable for many forming and pressing industrial operations. Unlike other types of stainless steel, ferritic stainless steel cannot be heat-treated, but it can be cold-worked.

Martensitic

Martensitic stainless steel is composed of 11-17% chromium, 0.12-0.35% nickel, and approximately 1.2% carbon. It is magnetic and can be heat-treated. Martensitic steel was the first type of stainless steel to be developed. Its applications in industries today include manufacturing various CNC equipment, such as cutting tools, and engineering equipment like hydraulic pumps, valves, and steam pumps.

2. Carbon Steel

Carbon steel is responsible for approximately 90% of the total steel production today. The carbon content of carbon steel ranges from 0.04% to 1.5%. We have established that many different elements can be added to iron when forming steel, and carbon steel relies mainly on carbon to determine its properties.

Depending on the amount of carbon added, there are three types of carbon steel: mild carbon steel, medium carbon steel, and high carbon steel. Mild carbon steel, also known as low-carbon steel, typically contains 0.04% to 0.3% carbon and is commonly used in rail components such as couplings, axles, and gears. Medium carbon steel contains between 0.3% and 0.6% carbon and is utilized in CNC cutting tools and various machine parts. High carbon steel, on the other hand, contains between 0.6% and 1.4% carbon and is employed in pistons, cylinders, rapid tooling, die casting, and railways.

Increasing the carbon content affects some of the properties of carbon steel, including a decrease in ductility and weldability. This also explains the better elongation properties of low-carbon steel compared to high-carbon steel. In rapid prototyping, the high flexibility of the metal in use is typically an advantage. Conversely, increasing the carbon content enhances the strength of the steel and toughness of the steel, which is another essential property to consider in rapid prototyping.

Nowadays, many manufacturers in the machining industry utilize a type of carbon steel known as free-machining steel. This type of steel contains additional elements like sulfur and phosphorous that have undergone specific treatments, resulting in better machinability of the steel without compromising other desirable qualities.

3. Alloy Steel

Alloy steels are steel grades that contain specific alloying elements in varying proportions to enhance specific characteristics of the steel. These characteristics include weldability, machinability, hardness, durability, corrosion and heat resistance, and ductility.

Some common alloying elements are manganese, aluminum, copper, vanadium, titanium, nickel, silicon, and chromium. Alloy steels can be further categorized into low alloy and high alloy. Low alloy steels contain between 1% and 5% alloying elements, while high alloy steels have around 5-50% alloying elements.

Alloy steels are primarily used in the manufacturing of automobile components, aerospace parts, and motor components. Their unique properties make them suitable for applications that require high performance and durability.

4. Tool Steel

Tool steels contain various carbon and alloy elements, such as tungsten, vanadium, cobalt, and molybdenum, which are usually present in different proportions. These elements can improve the heat resistance and durability of steel, making them suitable for manufacturing many curing and drilling tools in steel CNC machining. Tool steels are also essential in injection molds and pressing tools. However, the weldability of tool steels is very low.

There are myriad applications and uses of steel across various industries globally, with a significant focus on the CNC machining and rapid prototyping sector. Some notable areas where steel finds extensive use include:

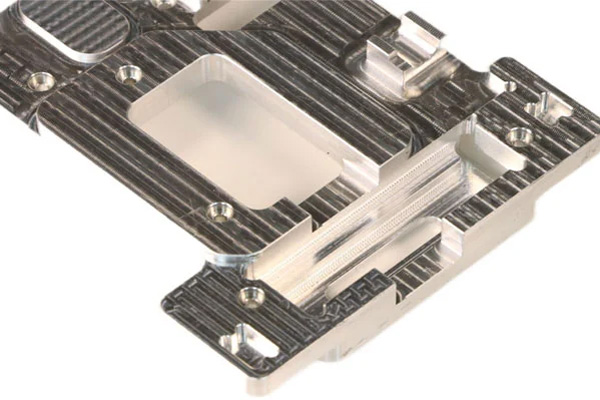

Industrial Components

Steel remains a cornerstone material in numerous industries worldwide, owing to its versatile properties that cater to diverse manufacturing needs. In rapid tooling and custom parts manufacturing, the high resistance to corrosion exhibited by steel ensures prolonged durability and optimal performance. Specifically, CNC stainless steel is extensively utilized for machining purposes, offering exceptional strength and corrosion resistance. Within industrial settings, steel is employed in a myriad of applications ranging from storage tanks to machinery and protective equipment.

Automobiles

Steel plays a pivotal role in automobile manufacturing, attributed to its lightweight nature and ease of formability. Advanced high-strength steel (AHSS) has gained prominence in modern automotive construction, boasting superior strength and formability characteristics. AHSS variants, incorporating retained austenite in a martensite matrix, offer enhanced formability while retaining crucial structural integrity.

Aerospace, Marine, and Railway Industries

Steel's lightweight and corrosion-resistant properties make it indispensable in the aerospace and marine sectors, where durability and performance are paramount. In aircraft and ship construction, steel components ensure structural integrity and longevity. Similarly, the railway industry heavily relies on steel for various critical components such as wheels, axles, bearings, and rail lines, where strength and durability are essential.

Energy Sector

Steel's exceptional durability makes it indispensable across all facets of the energy sector, from production to distribution. High-strength, carbon, stainless, and alloy steels are employed in the manufacture of energy production components, ensuring reliability and longevity under demanding operating conditions. Additionally, steel-reinforced cables and magnetic steel cores in transformers exemplify steel's versatility and utility in the energy industry.

Packaging

Steel's recyclability and corrosion resistance make it an ideal material for packaging applications. Low-carbon steel, prized for its machinability, is commonly used in packaging to safeguard goods from external environmental factors while ensuring sustainability through recyclability.

Domestic Appliances

Steel finds ubiquitous use in domestic appliances, encompassing a wide array of products such as utensils, cookware, and kitchen appliances. The choice of steel grade varies depending on the specific application, with stainless steel being a preferred option for its corrosion resistance and aesthetic appeal.

In summary, the versatility and inherent properties of steel render it indispensable across diverse industries, driving innovation and excellence in manufacturing processes and end-products alike.

Richconn is a leading provider of CNC machining services, offering a comprehensive range of metal fabrication solutions tailored to meet diverse manufacturing needs. Our CNC machining metals are among the core offerings, which encompass a wide selection of materials, including steel, renowned for its versatility and durability.

Choosing the appropriate steel grade for custom parts manufacturing is crucial to ensure optimal performance and durability of the final products. Here are some key considerations to guide your selection process:

Operating Environment:

Evaluate the environmental conditions the custom parts will be subjected to. Factors such as temperature, stress levels, and pH levels can influence the performance of different steel grades. Select a steel grade that offers the required resistance to environmental factors to ensure longevity and reliability.

Corrosion Resistance:

Consider the level of corrosion resistance required for the application. While steel is inherently resistant to corrosion, different grades offer varying degrees of protection. For applications exposed to corrosive environments, such as marine components, prioritize steel grades with high corrosion resistance, such as stainless steel.

Mechanical Properties:

Assess the mechanical properties needed for the custom parts, including ductility, strength, and hardness. The composition of steel grades influences these properties, with varying levels of nickel and other alloying elements affecting hardness and ductility. Choose a steel grade that aligns with the mechanical requirements of the application to ensure optimal performance under load.

Machinability:

Evaluate the machinability of different steel grades, considering the ease of modification during the manufacturing process. While high hardness may enhance durability, it can also pose challenges during machining. Opt for steel grades that offer a balance between hardness and machinability to streamline the fabrication process without compromising on quality.

Purpose of the Product:

Consider the intended application and functionality of the custom parts when selecting a steel grade. Different products may require specific properties, such as cutting and drilling capabilities or resistance to high temperatures. Tailor your choice of steel grade to suit the unique requirements of the end-use application to achieve optimal performance and longevity.

Cost:

Factor in the cost implications of different steel grades, considering both upfront expenses and long-term maintenance costs. While higher-grade steel may offer superior performance, it may also come at a higher price point. Strike a balance between cost and quality to maximize value for your custom parts manufacturing project.

By carefully evaluating these factors, you can effectively choose the right steel grade for custom parts manufacturing, ensuring superior quality, performance, and longevity of the final products.

Steel stands as the cornerstone of modern industrial manufacturing, offering unparalleled versatility and reliability across a myriad of applications. Its widespread use is underpinned by a plethora of advantageous properties, making it the material of choice for custom part prototyping and manufacturing.

Through our exploration of steel's properties, grades, and applications, it becomes evident that steel's adaptability and resilience are unmatched. Through our exploration of steel's properties, grades, and applications, it becomes evident that steel's adaptability and resilience are unmatched. Now, you can choose the right steel material for your custom prototyping and manufacturing projects. Hurry to contact Richconn for professional ideas!

Achieve Stunning Automotive Finishes with CNC Powder CoatingFebruary 29, 2024In the world of automotive customization, achieving a flawless and long-lasting finish is essential. Whether you are a car enthusiast looking to give your vehicle a new look or a professional in the i...view

Achieve Stunning Automotive Finishes with CNC Powder CoatingFebruary 29, 2024In the world of automotive customization, achieving a flawless and long-lasting finish is essential. Whether you are a car enthusiast looking to give your vehicle a new look or a professional in the i...view What Is Die Casting?March 7, 2024Do you know about die cast definition? This article introduces the definition, process, types, and everything you need to know about die cast.view

What Is Die Casting?March 7, 2024Do you know about die cast definition? This article introduces the definition, process, types, and everything you need to know about die cast.view Carbon Steel vs Cast Iron: Which Is Better for CNC Machining?November 24, 2023Carbon steel and cast iron are two common types of metal materials that are used for CNC machining. They are both composed of iron and carbon, but they have different amounts of carbon and different structures.view

Carbon Steel vs Cast Iron: Which Is Better for CNC Machining?November 24, 2023Carbon steel and cast iron are two common types of metal materials that are used for CNC machining. They are both composed of iron and carbon, but they have different amounts of carbon and different structures.view Thriving Outsourcing PartnershipsOctober 12, 2023Manufacturers now view outsourcing not just as a supplier relationship, but as a partnership. Lei Sheng, product manager at Richconn, explains why outsourcing projects with reliable partners make sense.view

Thriving Outsourcing PartnershipsOctober 12, 2023Manufacturers now view outsourcing not just as a supplier relationship, but as a partnership. Lei Sheng, product manager at Richconn, explains why outsourcing projects with reliable partners make sense.view 2024 China (Shenzhen) International Industrial Parts Exhibition (CIIPES-2024)January 3, 2024Exhibition OverviewIn order to further enhance the development of the industrial parts industry, fully display the cutting-edge equipment technology of the industrial parts industry, actively promote ...view

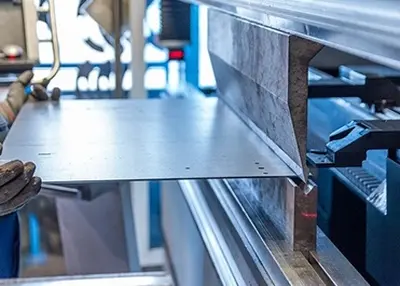

2024 China (Shenzhen) International Industrial Parts Exhibition (CIIPES-2024)January 3, 2024Exhibition OverviewIn order to further enhance the development of the industrial parts industry, fully display the cutting-edge equipment technology of the industrial parts industry, actively promote ...view 5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view

5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view