Are you in pursuit of engine components that combine precision, reliability, and performance? Your quest for top-notch CNC piston machining ends here. In this comprehensive guide, I will take you on a journey through the intricacies of CNC piston machining, shedding light on the processes, technologies, and services that define this critical aspect of engine manufacturing. By the time you reach the end of this article, you'll not only be well-versed in CNC piston machining but also equipped with insights to make informed decisions for your engineering needs.

Let's kick off our journey by understanding the fundamental concept of CNC piston machining. At its core, CNC piston machining is a technology-driven process that plays a pivotal role in the manufacturing of engine pistons. These critical components are at the heart of internal combustion engines, regulating the flow of air and fuel. But what sets CNC machining apart is the precision and consistency it offers in crafting these pistons.

CNC machining, short for Computer Numerical Control machining, is a technology that enables us to produce pistons with unparalleled precision and quality. By harnessing the power of automated machinery and advanced software, we can achieve tolerances and intricacies that manual processes could only dream of.

To delve deeper into the world of CNC piston machining, we need to understand how it works. The core of CNC machining lies in its ability to translate digital designs into physical products. Let's take a closer look at how this is achieved:

First, the process begins with meticulous design and programming. Skilled engineers create digital blueprints that dictate every aspect of the piston's geometry, from its dimensions to surface finishes. These designs are then fed into Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, which serves as the brain of the operation. The software generates a set of instructions, or G-codes, which guide the CNC machine in producing the piston.

Our exploration wouldn't be complete without breaking down the key steps involved in CNC piston machining. Each step plays a crucial role in shaping the final product, ensuring it meets the stringent quality standards:

1. Material Preparation: The process begins with the selection of the right material, typically aluminum or steel, known for its strength and heat resistance. The raw material is cut into manageable pieces.

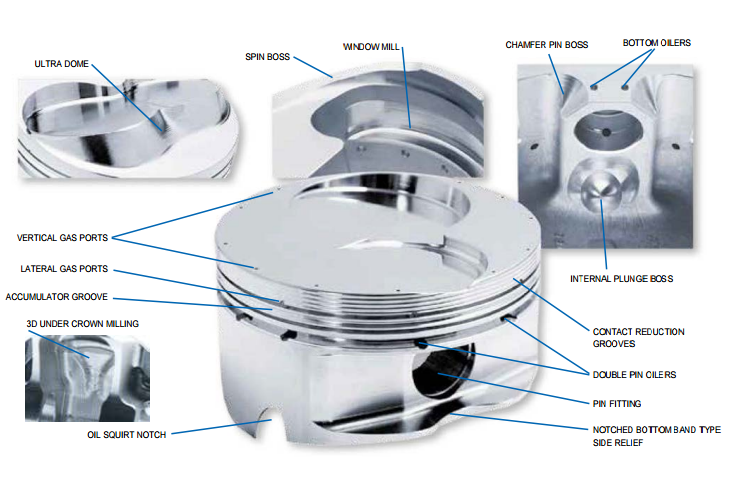

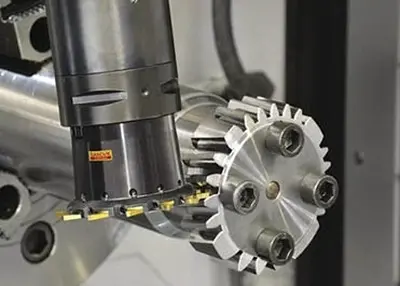

2. Turning and Boring: CNC lathes are employed to precisely shape the piston's outer diameter and inner bore, ensuring an exact fit within the engine cylinder.

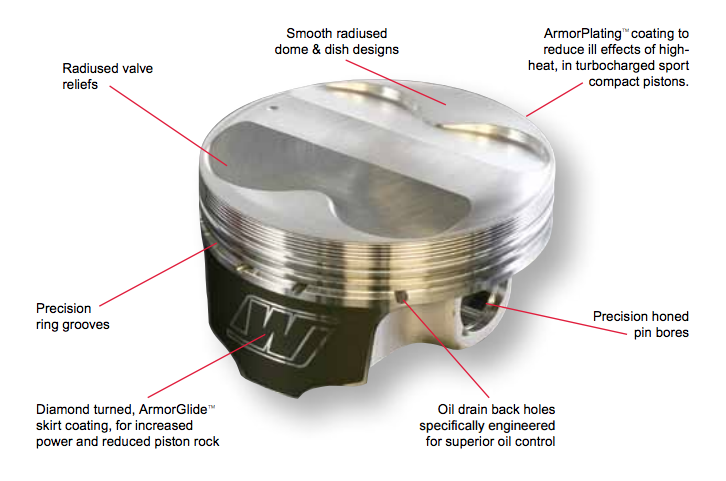

3. Milling: Intricate features, such as piston ring grooves and pin bores, are expertly milled into the piston's surface.

4. Drilling and Tapping: Holes for wrist pins and oil passages are accurately drilled, and threads are tapped as needed.

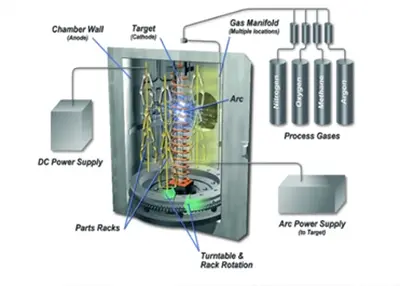

5. Surface Finishing: The piston undergoes surface treatments, such as anodizing or thermal barrier coatings, to enhance durability and performance.

6. Quality Control: Rigorous quality checks are conducted to verify dimensions, tolerances, and overall quality, ensuring the piston meets or exceeds specifications.

7. Precision Grinding: After milling, the piston may undergo precision grinding to achieve the desired surface finish and tight tolerances. This step ensures that the piston's contact with the cylinder wall is as smooth and precise as possible.

8. Assembly and Testing: Once the piston components are manufactured, they are carefully assembled, including attaching wrist pins, rings, and other necessary parts. The assembled pistons undergo rigorous testing to verify their functionality and quality.

9. Customization and Special Features: CNC piston machining allows for customization and the inclusion of special features. For example, pistons designed for high-performance applications may have features like oil cooling channels or advanced coatings to enhance durability.

Now that we've covered the intricacies of CNC piston machining, it's time to introduce you to Richconn – your trusted partner in delivering top-tier CNC machining services. We pride ourselves on our expertise and commitment to customer satisfaction. Our services encompass a wide array of solutions tailored to meet your specific needs.

At Richconn, we offer a comprehensive range of CNC piston machining services, from design to delivery. Our state-of-the-art facilities, experienced engineers, and stringent quality control measures ensure that every piston we produce is a masterpiece of precision and reliability.

CNC piston machining isn't confined to a single industry; it spans across various sectors, each with its unique demands. Let's explore the diverse applications of this technology:

3. Marine Engines: The marine industry relies on powerful and reliable engines. CNC piston machining ensures that marine engines operate smoothly and efficiently, making it crucial for maritime transport and shipping.

4. Industrial Power Generation: In the field of power generation, CNC piston machining contributes to the production of robust pistons for generators and turbines, guaranteeing reliable electricity production.

5. Motorcycle and Small Engine Manufacturing: Precision and durability are essential in the motorcycle and small engine industry. CNC piston machining ensures that these engines perform optimally.

As we wrap up our journey through the world of CNC piston machining, it's essential to glance at what the future holds. This industry is dynamic, and constant innovation shapes its course:

3. Sustainable Materials: With a growing emphasis on environmental sustainability, manufacturers are exploring the use of lightweight and eco-friendly materials in piston manufacturing.

4. 3D Printing Advancements: Additive manufacturing is on the rise, offering the potential for rapid prototyping and complex geometries in piston design.

5. IoT Integration: The integration of the Internet of Things (IoT) and data analytics in CNC machining processes will enable real-time monitoring, predictive maintenance, and enhanced productivity.

The CNC piston machining is a pivotal aspect of modern engineering, and Richconn is here to deliver the precision and quality your projects demand. By understanding the intricate processes and technologies behind CNC machining, you are better equipped to make informed decisions and harness the full potential of this remarkable technology. Get in touch with us at Richconn, and let's embark on a journey of precision and reliability together. Your next engineering masterpiece awaits.

Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view

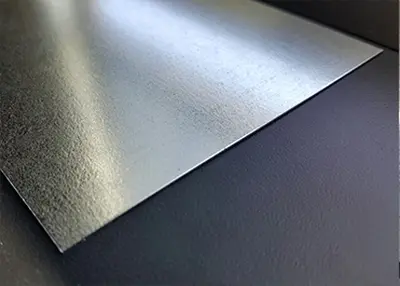

Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view Galvanized Sheet Metal: Unveiling the Power of a Versatile MaterialSeptember 28, 2023When it comes to construction and engineering, one material that stands out for its versatility and durability is galvanized sheet metal. In this comprehensive guide, I will take you on a journey through the world of galvanized sheet metal, exploring its various facets, applications, and even its synergy with CNC technology.view

Galvanized Sheet Metal: Unveiling the Power of a Versatile MaterialSeptember 28, 2023When it comes to construction and engineering, one material that stands out for its versatility and durability is galvanized sheet metal. In this comprehensive guide, I will take you on a journey through the world of galvanized sheet metal, exploring its various facets, applications, and even its synergy with CNC technology.view What is the Basic Principle of Electrophoresis Coating?September 16, 2022Electrophoresis coating is a coating method that uses an external electric field to make particles such as pigments and resins suspended in an electrophoretic solution directionally migrate and deposi...view

What is the Basic Principle of Electrophoresis Coating?September 16, 2022Electrophoresis coating is a coating method that uses an external electric field to make particles such as pigments and resins suspended in an electrophoretic solution directionally migrate and deposi...view How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view

How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view In-Depth Overview: What Are Non-Ferrous Metals?August 7, 2023Metals may be found everywhere and are used for a variety of purposes. There are two different types of metals, ferrous and non-ferrous—based on how much iron they contain. Non-ferrous metals are a c...view

In-Depth Overview: What Are Non-Ferrous Metals?August 7, 2023Metals may be found everywhere and are used for a variety of purposes. There are two different types of metals, ferrous and non-ferrous—based on how much iron they contain. Non-ferrous metals are a c...view CNC Machine vs 3D Printer: A Comprehensive ComparisonNovember 6, 2023As the proud owner of Richconn, a CNC machining service provider, I understand the importance of choosing the right manufacturing technology for your production needs. The decision between CNC machines and 3D printers can be a daunting one, and that's why I'm here to provide you with a comprehensive comparison to help you make an informed choice.view

CNC Machine vs 3D Printer: A Comprehensive ComparisonNovember 6, 2023As the proud owner of Richconn, a CNC machining service provider, I understand the importance of choosing the right manufacturing technology for your production needs. The decision between CNC machines and 3D printers can be a daunting one, and that's why I'm here to provide you with a comprehensive comparison to help you make an informed choice.view

EN

EN

ru

ru