Create fast and scalable rapid prototypes and production parts for manufacturing companies and become the global leader in custom CNC milling machining.

※ 10 years of production and customization experience

※ 24-hour solution response

※ 30 CNC processing equipment

※ 50 high-quality production personnel

※ 100 minutes for efficient sample creation

- Milled at higher rates of progress and with greater precision, resulting in the finishing of parts with precise features and specifications.

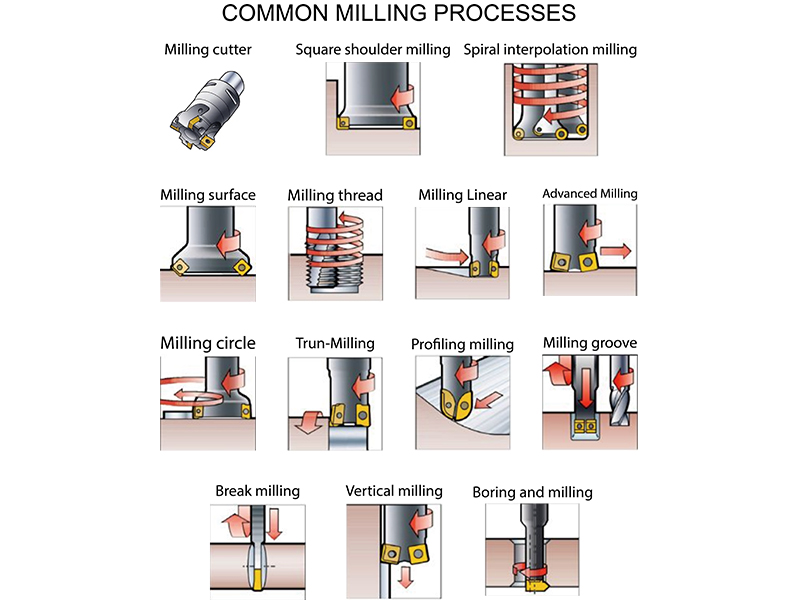

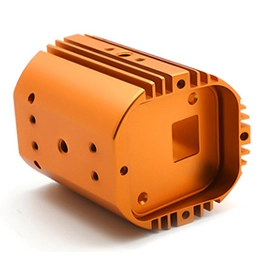

CNC milling is controlled by a computer and uses rotating, multi-point cutting tools to gradually remove material from a workpiece and produce a custom-designed part or product. The process is suitable for processing a variety of materials, such as metals, plastics, and wood, and produces a variety of custom-designed parts and products. It is also suitable for producing high-precision, close-tolerance parts in prototypes, one-offs and small to medium-sized production runs. The versatility of the CNC milled parts process allows it to be used in a wide range of industries and a variety of part features and designs, including slots, chamfers, threads and cavities.

The CNC Milling processing capabilities and scope that precision machining China can provide are as follows:

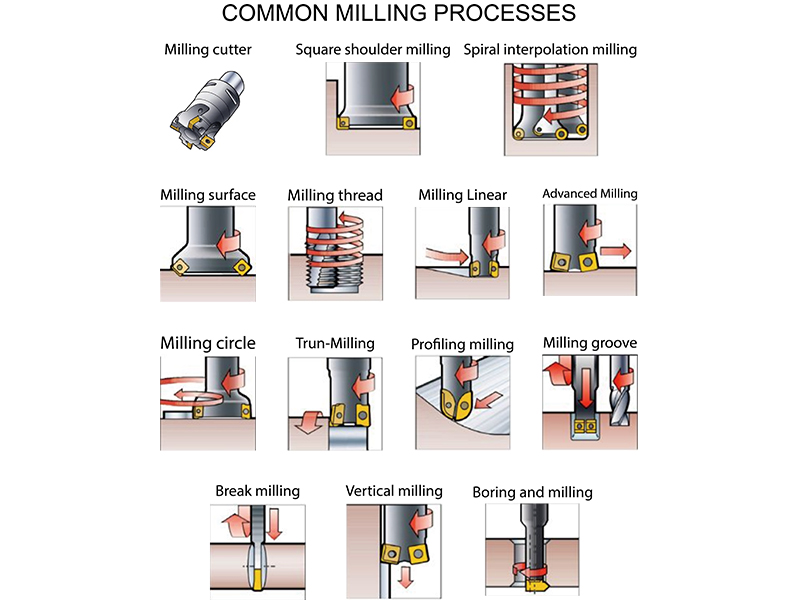

| Material | copper, aluminum, iron, plastic, alloy, etc | ||||

| Type | Numerical | Recommended accuracy | Limit accuracy | Recommended roughness | Limit roughness |

| Size | 0-Φ0.5 | ±0.03 | ±0.005 | 1.6 | 0.8 |

| Φ0.5-Φ6 | ±0.05 | ±0.005 | 1.6 | 0.8 | |

| Φ6-Φ30 | ±0.1 | ±0.01 | 1.6 | 0.8 | |

| Φ30-Φ120 | ±0.15 | ±0.1 | 1.6 | 0.8 | |

| ≥Φ120 | ±0.2 | ±0.05 | 3.2 | 1.6 | |

| Angle | <10° | ±1.0° | ±0.5° | - | - |

| 10°≤-≥150° | ±0.5° | ±0.2° | - | - | |

| Flatness | ≤30 | ▱0.1 | ▱0.05 | - | - |

| >30-100 | ▱0.15 | ▱0.1 | - | - | |

| >100 | ▱0.2 | ▱0.1 | - | - | |

| Verticality | ≤100 | ⊥0.2 | ⊥0.1 | - | - |

| >100-300 | ⊥0.3 | ⊥0.15 | - | - | |

| Symmetry | i0.1 | - | - | ||

Located in Shenzhen, the heart of China's technology and manufacturing center, we serve as your CNC mill turn center, providing large-scale support for product improvements and cost reductions for your product line.

Richconn's experienced and skilled project engineering team will analyze the process for each part, customize the most appropriate machining solution for your CNC milling projects, and provide an all-in-one service with low cost and high quality.

Richconn is committed to providing top quality. We offer special packaging options for your CNC milling parts to ensure that each part is delivered undamaged, and Richconn guarantees that you get exactly what you order.

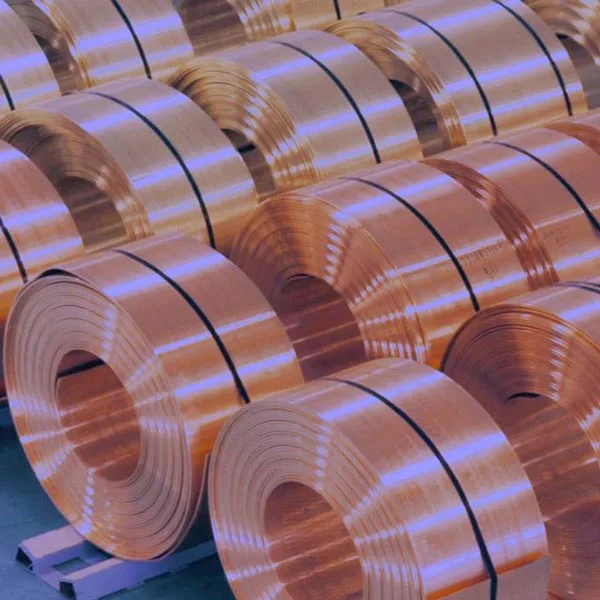

The workshop is fully equipped with high-precision machining equipment (5-axis CNC machine tools, Swiss CNC lathes, etc.) and inspection instruments (three-dimensional yuan, two-dimensional yuan, micrometer, spectrometer, etc.), with an accuracy of up to +/-0.01mm, and fast delivery.

Our business includes optimization of product design analysis, budget proposals, first implementation of conceptual products, rapid prototyping, mass production of molds and support for modification of mold design and manufacturing, as well as small batch production of molds.

Richconn engineers can help customers select the right material for the part being developed. For example, the engineers will evaluate whether the material you specify will meet the requirements when stamped, or whether it is likely to have problems such as cracking during production. If so, they will suggest alternatives

To ensure the durability of the entire core stamping of the part, we have a complete in-house facility to conduct a range of tests (including salt spray tests, spring stiffness tests, film thickness tests)

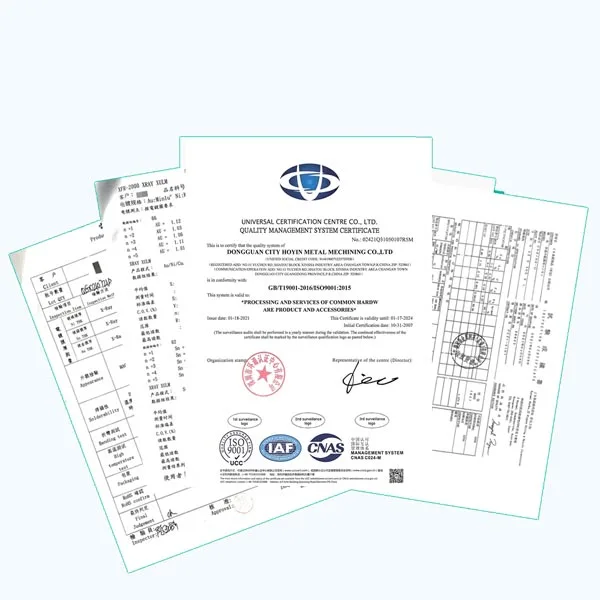

ISO 9001 (International Organization for Standardization), we also understand UL, CSA, NSF, ETL and CE standards.

CNC milling is more applied to complex surfaces, step surfaces, helical surfaces (threads), inclined surfaces (taper surfaces), chamfers, grooves (keyways, grooves, T-grooves, etc.) with complex shapes, and complete processing of parts without replacement.

In part processing of CNC milling working, automatic tool change can greatly improve efficiency. Because of its flexible processing characteristics, NC milling is the absolute main processing technology in the whole processing industry.

CNC milling is especially suitable for parts with strong adaptability to materials and difficult to control size or parts with particularly complex contour shapes.

CNC milling operation can process parts that are difficult or impossible to be processed by ordinary turn-milling machine tools, such as linear surfaces, circular arc surfaces, etc.

After one clamping and positioning, the precision CNC milling machine can complete the processing of multiple processing procedures and multi-faceted and multi-type processes, such as milling, chamfering, milling round hole, drilling, reaming, reaming, boring, thread milling, and so on.

The equipment has a high degree of automation, especially the equipment with tool magazines and automatic tool changes. Reduce labor intensity and repeated the tooling process. When the quality needs to be checked, the processing can be stopped at any time, and the continuous production can not be adjusted after the inspection.

If you are a component fabricator, take advantage of our competitive ex-factory prices and our service that will keep you smiling.

Our strong technical support can provide valuable insight and help you determine which hardware finishing method is best for your end product.

Whether you're looking for customized new components for a specific application or the latest equipment, our team is ready to support you.

EN

EN

ru

ru