The surface finishing process is the final step in CNC machining. Different techniques eliminate surface irregularities, improve part appearance, and add strength and resistance for increased functionality. The finishing technique you use depends on specific requirements, such as industry standards, the application of the part, and the materials you are working with.

At Richconn, we're quality-driven and ready to Custom Manufacturing parts for a variety of uses. Whether you insist on tight dimensional tolerances and a smooth finish, or you need additional corrosion and wear resistance, our surface finishes services for CNC machining can produce exactly what you need.

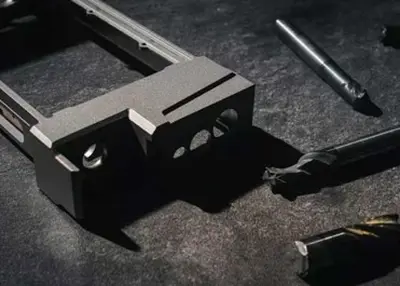

CNC machining is subtractive and may leave tool marks or surface imperfections on the final part.The standard surface finish of CNC machined parts reduces the roughness, wear resistance, and other cosmetic properties of custom metal parts, while also improving aesthetics and functionality.

Some common types of CNC surface finish include:

Machined

Bead blasting

Wet sanding

Fire polishing

Steam polishing

If you are working with plastics or similar non-metallic materials, choose your surface finish carefully. Pay attention to the application, texture, and strength of the material and component, and avoid using high-temperature or heavy-impact techniques on softer components.

These are some common machining finishes for plastics and similar materials - consider each finish to determine which solution best meets your requirements and preferences.

Machined parts are fresh off the line with slight tool marks and average surface roughness, and many are molded to already have a specific texture or finished look. The average roughness of a part is the difference between the actual machining and the ideal machined surface roughness and may vary from use case to use case.

Benefits of machined finishes include consistency across multiple units and the tightest dimensional tolerances. Machined finishes can support any material and are ideal for parts that require extremely tight tolerances and dimensional integrity rather than aesthetics. The disadvantages of this surface finish are visible tool marks on the final part and a lack of protective coatings.

Bead blasting is a finishing technique in which parts with small glass beads are blasted by means of a pressurized air gun. This process primarily improves aesthetics to create a matte or satin finish with a light texture. It is a primary surface treatment that mechanically alters the surface by removing excess material to alter or remove machining marks, resulting in a smooth surface.

An advantage of beadblasting is its uniform and textured surface. However, it has little effect on tolerances and can affect critical dimensions of the surface. It is also a manual process that can vary in terms of air pressure and the size of the glass beads, so the results are not always the same.

If beading plastic parts, make sure they can withstand impact. If not, consider injection molding as an alternative to achieving a matte finish.

Wet sanding is ideal for finishing plastic parts in preparation for paint or varnish polishing. The process consists of using fine grit silicon carbide sandpaper soaked in water and then sanding gently in a circular motion. Transitioning from medium to low grit sandpaper helps to finish the part with a smoother surface.

After smoothing, you can apply and polish a plastic-safe varnish to promote shine and luster.

Fire polishing is not suitable for all plastic and glass parts, but it is a very effective way to finish CNC parts if the material can withstand the temperature. The operator uses an open flame to melt the surface layer of the part, keeping the flame at a specific temperature and angle at all times. When the surface reaches a partial melting point, it begins to strain and move, creating a smooth, polished surface.

Depending on the material you're finishing, fire polishing may turn a part with a cloudy surface into a clear, flat surface. Fire polishing also reduces any bumps or bulges that form during the manufacturing process.

Since fire polishing involves an open flame and careful application, it is best left to trained professionals with experience working with plastic CNC parts.

Polishing plastics with chemical vapors is an effective way to clarify matte, opaque or dull plastics, leaving the final part smooth and shiny. You can use a polishing wheel to smooth edges and inconsistencies while enhancing the natural qualities of the material. CNC parts with highly visible defects may need to be polished before applying vapor polishing.

Yes, you can combine different CNC surface finishes to take advantage of their different properties. For example, sandblasting helps create a specific matte texture before applying another finish.

The final stage of the CNC machining process is CNC machining surface finish, which removes imperfections from a part in order to achieve a smooth, aesthetically pleasing surface while forging a stronger part that is more resistant to corrosion and wear.

Surface Roughness and Surface Finish describe the physical surface of a part, while Surface Finish refers to a specific process that creates a smooth and strong surface. Some methods add material, while others subtract or use heat and other techniques to alter the surface.

Surface finish typically consists of three characteristics, including the layup of the part, roughness, and corrugation.

In some cases, you may need to mask holes and other critical areas before applying a surface finish to a CNC part. Masking protects the surface or hole from additional layers that add thickness and may interfere with the tight tolerances of the part and other components such as press fit and threaded holes.

Components with holes should be plugged with rubber or masking paint. They are removed once the finishing process is complete and has had enough time to cure properly.

Some surface finishing techniques are more complex than others. For example, wet sanding plastic parts usually requires wiping and resetting the applicator throughout the process, while flame and steam polishing require less manual involvement.

Before selecting and applying a surface finish, consider how each part interacts with other components, including how often they come into contact and the amount of force or resistance. This will help you select the proper level of surface protection to keep the component structurally intact after machining.

3D Printed Plastic: Prototypes: What's Next?October 10, 2023Manufacturing technologies are continually evolving, opening up new opportunities for manufacturers throughout the entire life cycle. More and more product developers are choosing to switch from one production process to another or switch between processes as needed.view

3D Printed Plastic: Prototypes: What's Next?October 10, 2023Manufacturing technologies are continually evolving, opening up new opportunities for manufacturers throughout the entire life cycle. More and more product developers are choosing to switch from one production process to another or switch between processes as needed.view Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view

Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view

Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view Find the Right Corrosion Resistant MetalsOctober 16, 2023Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.view

Find the Right Corrosion Resistant MetalsOctober 16, 2023Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.view What Are the High Temperature and Corrosion Resistant High Hardness Alloy Wear Resistant Metal Materials?October 30, 2023Corrosion-resistant metals are used in a wide range of applications, from the culinary industry to aerospace applications. Like most metals, they provide structural strength and heat resistance, but the metals listed in this article are also more resistant to corrosion than others.view

What Are the High Temperature and Corrosion Resistant High Hardness Alloy Wear Resistant Metal Materials?October 30, 2023Corrosion-resistant metals are used in a wide range of applications, from the culinary industry to aerospace applications. Like most metals, they provide structural strength and heat resistance, but the metals listed in this article are also more resistant to corrosion than others.view 6 Benefits of Partnering With a Trusted CNC CompanySeptember 13, 2023Why choose a CNC company to partner with? Let’s explore the advantages of partnering with a CNC company for precision machining and top-quality parts.view

6 Benefits of Partnering With a Trusted CNC CompanySeptember 13, 2023Why choose a CNC company to partner with? Let’s explore the advantages of partnering with a CNC company for precision machining and top-quality parts.view

EN

EN

ru

ru