Welcome to the realm where precision meets creativity, where the art of CNC (Computer Numerical Control) technology converges with the transparent beauty of acrylic. In this journey, we will delve into the intricate world of CNC Acrylic machining, unveiling its applications, design inspirations, material synergies, and real-world case studies.

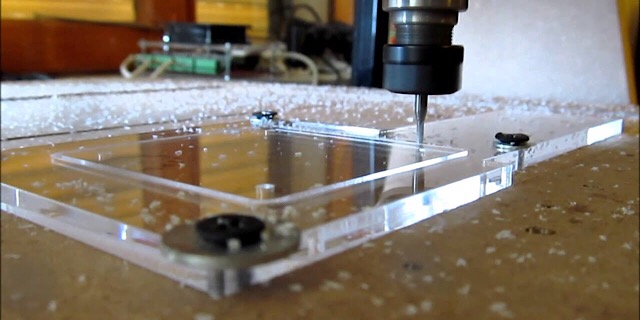

In the fast-paced landscape of modern manufacturing, the fusion of CNC technology with acrylic opens doors to a realm of possibilities. CNC Acrylic machining, at its core, involves the use of computer-controlled machinery to carve, cut, and shape acrylic sheets with unparalleled precision.

The precision afforded by CNC technology in acrylic machining is a game-changer. It allows for intricate designs and complex patterns that were once challenging with traditional methods. The marriage of these two elements introduces a new era of creativity and precision in the world of manufacturing.

Understanding the inner workings of CNC technology in acrylic processing is crucial to appreciating its transformative impact. CNC machines operate based on coded instructions, translating digital designs into tangible, precisely crafted acrylic products.

Precision is the hallmark of CNC technology in acrylic processing. The process begins with the creation of a digital design, which is then translated into a set of instructions for the CNC machine. This allows for consistent, high-quality results, whether producing a single prototype or a large batch of acrylic components.

Table 1: Advantages of CNC Acrylic Machining

| Advantages | Description |

|---|---|

| Precision | Achieves intricate details and complex patterns. |

| Consistency | Ensures uniform quality across multiple pieces. |

| Efficiency | Reduces production time compared to traditional methods. |

| Customization | Allows for personalized designs and bespoke creations. |

The marriage of CNC technology and acrylic opens a gateway to unparalleled creativity. Designers and artists now have the tools to push the boundaries of what's possible with acrylic, giving rise to innovative and visually stunning creations.

Exploring the creative potential of CNC Acrylic machining unveils a world of possibilities. From intricate sculptures to functional art pieces, the precision offered by CNC technology allows artists to translate their visions into reality with unprecedented accuracy.

Table 2: Examples of CNC Acrylic Designs

| Application | Description |

|---|---|

| Artistic Sculptures | Detailed sculptures with intricate patterns. |

| Signage and Branding | Precision-cut logos and lettering for branding. |

| Custom Display Cases | Tailored solutions for showcasing products. |

| Architectural Elements | Acrylic components for modern architectural designs. |

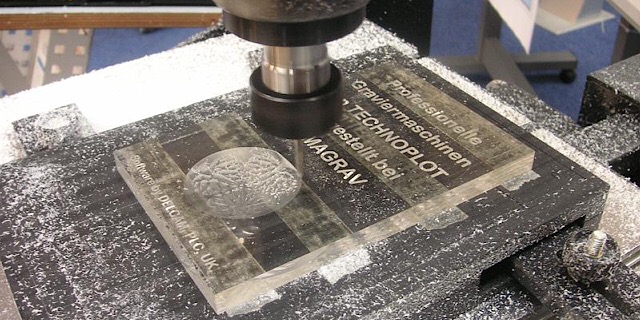

Understanding the unique characteristics of acrylic is pivotal in optimizing the CNC machining process. Acrylic, also known as PMMA (polymethyl methacrylate), boasts transparency, durability, and versatility. In CNC Acrylic machining, these properties are harnessed to create products that marry form and function seamlessly.

CNC Acrylic machining relies on the inherent properties of acrylic to achieve optimal results. The transparency of acrylic allows for the creation of crystal-clear designs, making it a popular choice for artistic and decorative applications. Additionally, its durability ensures the longevity of CNC-machined products, even in demanding environments.

Table 3: Acrylic Properties and CNC Processing Synergy

| Property | Synergy with CNC Acrylic Machining |

|---|---|

| Transparency | Ideal for creating clear and aesthetically pleasing designs. |

| Durability | Ensures longevity, making CNC Acrylic products robust. |

| Versatility | Allows for a wide range of applications and design options. |

| UV Resistance | Suitable for outdoor applications without yellowing. |

The versatility of CNC Acrylic machining extends across various industries, offering solutions that range from functional components to artistic expressions. Let's explore how CNC Acrylic is making an impact in real-world applications.

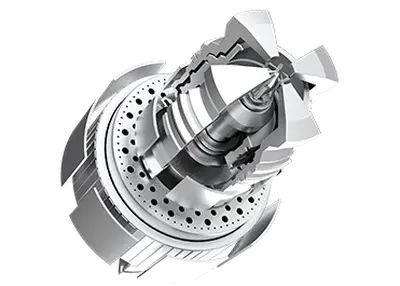

In industrial settings, CNC Acrylic components find applications in machinery, where precision and durability are paramount. In the artistic realm, sculptures and installations leverage CNC Acrylic machining for intricate detailing. Signage and branding benefit from the precision-cut logos and letters, ensuring a polished and professional appearance.

Table 4: Industry-specific Applications of CNC Acrylic Machining

| Industry | CNC Acrylic Application |

|---|---|

| Industrial Manufacturing | Precision components for machinery and equipment. |

| Art and Sculpture | Detailed sculptures and artistic installations. |

| Advertising and Branding | Logo and lettering for clear and impactful signage. |

| Retail Displays | Custom display cases for showcasing products. |

For those navigating the landscape of CNC Acrylic machining services, it's crucial to align with a provider that not only meets the criteria for precision and quality but also understands the unique demands of acrylic materials. One standout option worth considering is Richconn, a trusted name in precision machining.

Richconn: Precision Beyond Measure

Richconn has established itself as a leader in precise machining, offering a spectrum of services that extend seamlessly into the realm of CNC Acrylic machining. Here's why Richconn stands out:

Proven Precision and Quality: Richconn boasts a track record of delivering products with meticulous precision and uncompromising quality. The company's commitment to excellence ensures that CNC-machined acrylic components meet the highest industry standards.

Customization Expertise: Recognizing the diverse design requirements of clients, Richconn excels in offering customization options. Whether it's a complex pattern or a unique design, their team is equipped to bring your vision to life.

Material Mastery: Richconn's expertise extends beyond machinery. The team possesses a deep understanding of acrylic material properties, ensuring that the Acrylic CNC machining services process is optimized for the unique characteristics of the material.

State-of-the-Art Technology: Staying at the forefront of technology is a priority for Richconn. The company invests in advanced CNC machines and technology infrastructure, ensuring that clients benefit from the latest innovations in precision machining.

Efficient Turnaround: Richconn understands the importance of timely delivery. Their efficient production processes and commitment to meeting deadlines make them a reliable partner for projects of various scales.

By choosing Richconn as your CNC Acrylic machining service provider, you align with a company that blends expertise, technology, and a commitment to excellence.

Table 7: Why Choose Richconn for CNC Acrylic Machining

| Criteria | Richconn's Offerings |

|---|---|

| Precision and Quality | Proven track record of delivering precision and high-quality products. |

| Customization Options | Expertise in accommodating diverse design requirements. |

| Material Mastery | Deep understanding of acrylic material properties and behavior. |

| Technology Capabilities | Investment in state-of-the-art CNC machines and technology infrastructure. |

| Turnaround Time | Efficient production processes for timely delivery. |

When navigating the landscape of CNC Acrylic machining services, consider Richconn as your partner for precision and innovation.

As technology advances, so does the potential of CNC Acrylic machining. Let's explore the emerging trends shaping the future of this innovative synergy between precision technology and acrylic material.

The future of CNC Acrylic machining holds exciting possibilities. Advances in CNC technology are likely to bring forth even more precise and efficient machines, enabling intricate designs that were once deemed challenging. Additionally, continuous research into acrylic materials may lead to the development of new variants, expanding the application possibilities.

Table 6: Future Trends in CNC Acrylic Machining

| Trend | Description |

|---|---|

| Advanced CNC Technology | Evolving CNC machines with enhanced precision and capabilities. |

| Smart Manufacturing | Integration of IoT and AI for smarter and more efficient production. |

| New Acrylic Material Variants | Development of acrylic variants with enhanced properties. |

| Sustainable Practices | Emphasis on eco-friendly processes and material choices. |

The success of CNC Acrylic machining is closely tied to the initial design phase. Achieving the desired precision and aesthetics requires careful consideration of various factors.

Designing for CNC Acrylic machining involves more than creating visually appealing concepts. Factors such as toolpath optimization, material constraints, and the intricacies of CNC programming play a pivotal role. Designers must collaborate closely with CNC programmers to ensure the seamless translation of digital designs into tangible acrylic masterpieces.

Table 8: Key Design Considerations for CNC Acrylic Machining

| Consideration | Description |

|---|---|

| Toolpath Optimization | Ensuring efficient tool movement for precise machining. |

| Material Constraints | Adapting designs to suit the unique properties of acrylic. |

| CNC Programming Collaboration | Collaborating with programmers for accurate translation. |

| Intricate Detailing | Maximizing CNC capabilities for intricate design elements. |

While CNC Acrylic machining offers unparalleled precision, it comes with its set of challenges. Identifying and addressing these challenges is crucial to ensuring a smooth production process.

CNC Acrylic machining challenges can range from tool wear to material-specific issues. Understanding and mitigating these challenges is vital for maintaining efficiency and achieving the desired level of precision.

Table 9: Common Challenges in CNC Acrylic Machining

| Challenge | Description |

|---|---|

| Tool Wear | Managing wear and tear of cutting tools during prolonged use. |

| Heat Generation | Addressing issues related to heat buildup during machining. |

| Material Chipping | Preventing chipping or cracking of acrylic during machining. |

| Precision Maintenance | Ensuring ongoing precision through regular machine calibration. |

Understanding the nuances of design considerations and potential challenges sets the stage for a successful CNC Acrylic machining venture.

Ensuring the precision and quality of CNC Acrylic machining goes beyond the initial design and production phases. Robust quality control measures are essential to guarantee that the final products meet the intended specifications.

Quality control in CNC Acrylic machining involves a multi-faceted approach. From inspecting raw materials for consistency to conducting meticulous checks at various stages of the machining process, implementing a comprehensive quality control system is imperative for delivering flawless acrylic components.

Table 10: Components of Effective Quality Control in CNC Acrylic Machining

| Component | Description |

|---|---|

| Raw Material Inspection | Ensuring consistency and quality of acrylic materials. |

| In-Process Inspections | Periodic checks during machining to detect deviations. |

| Final Product Verification | Comprehensive inspection before the products are dispatched. |

| Calibration and Maintenance | Regular calibration of CNC machines for sustained accuracy. |

As industries strive for sustainability, understanding the environmental impact of manufacturing processes is crucial. CNC Acrylic machining, while highly precise, comes with considerations regarding its ecological footprint.

CNC Acrylic machining, when compared to traditional methods, can be considered more environmentally friendly. The precision it offers reduces material waste, and advancements in coolant systems contribute to energy efficiency. However, the choice of acrylic materials and the disposal of waste still pose environmental challenges that must be addressed.

Table 11: Environmental Considerations in CNC Acrylic Machining

| Consideration | Description |

|---|---|

| Material Selection | Choosing eco-friendly acrylic variants and recyclable materials. |

| Waste Management | Implementing effective strategies for recycling acrylic waste. |

| Energy Efficiency | Adopting energy-efficient machining processes. |

| Emissions Reduction | Minimizing emissions through advanced machining technologies. |

In this era of heightened environmental awareness, understanding and mitigating the environmental impact of CNC Acrylic machining is a responsibility that manufacturers must shoulder.

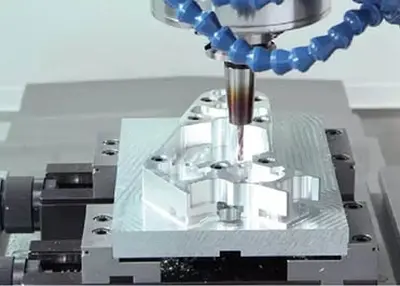

Innovation serves as the driving force behind advancements in CNC Acrylic machining. From the adoption of new materials to the integration of cutting-edge technologies, staying at the forefront of innovation is pivotal for manufacturers and designers.

Innovations in CNC Acrylic machining are diverse. This includes the exploration of advanced tool materials, the incorporation of AI-driven programming for enhanced precision, and the integration of sustainable practices into machining processes. Embracing these innovations ensures that CNC Acrylic machining remains a dynamic and forward-looking field.

Table 14: Noteworthy Innovations in CNC Acrylic Machining

| Innovation | Description |

|---|---|

| Advanced Tool Materials | Utilizing high-performance tool materials for extended durability. |

| AI-Driven Programming | Implementing AI algorithms for optimizing CNC programming. |

| Sustainable Machining Practices | Introducing eco-friendly approaches in CNC Acrylic machining. |

| Nanotechnology Applications | Exploring nanoscale machining for unparalleled precision. |

As we gaze into the future of CNC Acrylic machining, the potential for growth and transformation is boundless. From further advancements in precision to the exploration of new materials, the evolution of this field is poised to redefine the possibilities.

The future of CNC Acrylic machining holds promise in several areas. Continued improvements in CNC technology will likely lead to even higher levels of precision, opening avenues for more intricate designs. Additionally, the development of acrylic variants with enhanced properties may expand the application range, enabling CNC Acrylic machining to penetrate new industries and creative realms.

Table 15: Anticipated Developments in the Future of CNC Acrylic Machining

| Development | Description |

|---|---|

| Enhanced Precision | Further advancements in CNC technology for unparalleled precision. |

| New Acrylic Material Variants | Development of acrylic materials with advanced properties. |

| Industry Diversification | Expansion of CNC Acrylic machining into new industries. |

| Integration of Smart Systems | Incorporating IoT and smart technologies for seamless machining. |

The journey of CNC Acrylic machining is one marked by precision, creativity, and a commitment to pushing the boundaries of what's possible.

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view The Comprehensive Guide: Aerospace CNC Machining Parts and ComponentsJuly 12, 2024CNC machining is widely used in the aerospace industry and aerospace CNC machining parts often require high precision and attention to detail. Let’s dive into cutting-edge technologies crafting vital parts for the aerospace industry in this comprehensive guide.view

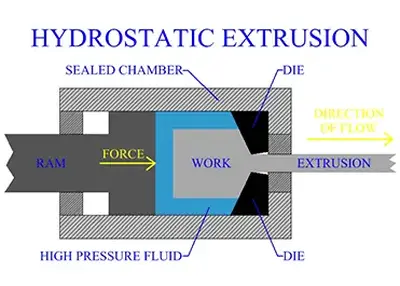

The Comprehensive Guide: Aerospace CNC Machining Parts and ComponentsJuly 12, 2024CNC machining is widely used in the aerospace industry and aerospace CNC machining parts often require high precision and attention to detail. Let’s dive into cutting-edge technologies crafting vital parts for the aerospace industry in this comprehensive guide.view Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view CNC Router Machinery: Unveiling the Core of Modern ManufacturingNovember 2, 2023Are you ready to explore the cutting-edge world of CNC router machinery? Whether you are a seasoned professional in the field or someone just getting started, this comprehensive guide will equip you with the knowledge you need to harness the full potential of CNC router machinery. From understanding the fundamentals to exploring innovative services, let's dive in and take your CNC router experience to the next level.view

CNC Router Machinery: Unveiling the Core of Modern ManufacturingNovember 2, 2023Are you ready to explore the cutting-edge world of CNC router machinery? Whether you are a seasoned professional in the field or someone just getting started, this comprehensive guide will equip you with the knowledge you need to harness the full potential of CNC router machinery. From understanding the fundamentals to exploring innovative services, let's dive in and take your CNC router experience to the next level.view 7 Types of CNC MachinesSeptember 13, 2023Here are the types of CNC machine. Read on to learn all you should know about this topic to help you select the best CNC machine type.view

7 Types of CNC MachinesSeptember 13, 2023Here are the types of CNC machine. Read on to learn all you should know about this topic to help you select the best CNC machine type.view Richconn Expands its Rapid CNC Service with High Performance Aluminum 5083October 11, 2023As the world's leading rapid prototyping companies, we have added Aluminum 5083-H111 (3.3547 or AlMg4.5Mn0.7) to our line of more than 40 in-stock metals and plastics materials for quick turnaround CNC service.view

Richconn Expands its Rapid CNC Service with High Performance Aluminum 5083October 11, 2023As the world's leading rapid prototyping companies, we have added Aluminum 5083-H111 (3.3547 or AlMg4.5Mn0.7) to our line of more than 40 in-stock metals and plastics materials for quick turnaround CNC service.view