With the continuous improvement of manufacturing quality requirements, steel plates, as an important basic material and mechanical component, their flatness directly affects the precision of subsequent processing and final products. This article will specifically analyze why flattening steel plates is extremely important for obtaining high-precision manufacturing, and what kind of CNC machining process should be used for efficient flattening.

Compared with directly using raw steel plates, flattened steel plates can significantly improve machining quality and performance. Specific advantages include:

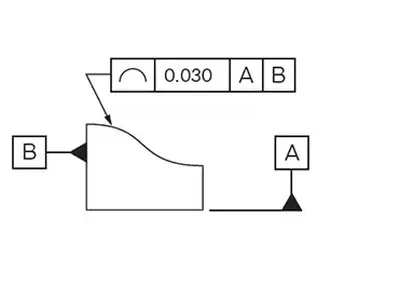

1. Improve machining and use accuracy, accuracy up to 0.01mm

2. Improve appearance quality, can reduce surface bumps greater than 0.5mm

3. Extend service life, life can be increased by more than 15%

4. Prevent secondary deformation, deformation can be reduced by 80%

5. Improve efficiency of subsequent processing, can save 60% of machining time

6. Reduce machining costs, costs can be reduced by 30%

7. Improve product performance, increase mechanical strength by up to 20%

Compared with traditional manual flattening methods, CNC milling operation and other steel plate flattening has the following advantages:

1. Reduce human factors, quality pass rate up to 99%

2. High-efficiency batch processing, daily output per machine up to 500 pieces

3. Higher machining accuracy, up to ±0.02mm

4. Easy programming adjustment, program optimization time can save 70%

5. Reduce labor costs, can save 80% of manpower

6. Wider applicability, can process steel plates with thickness of 5-300mm

7. Better repeatability, error between plates can be controlled within 0.01mm

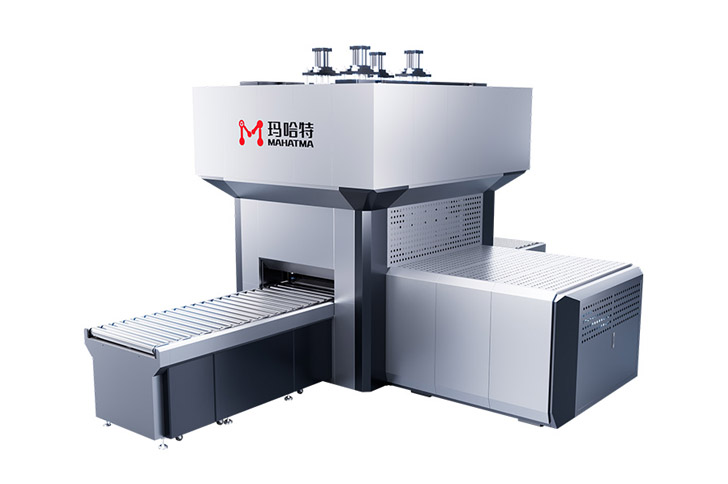

steel plate flattening machine

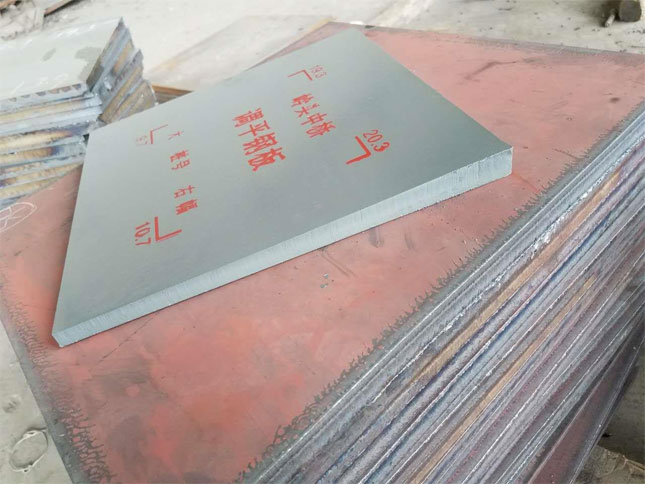

In the mechanical manufacturing industry, steel plates are important basic materials and components. In order to obtain high-precision mechanical products, it is necessary to use precisely flattened steel plates for processing and manufacturing.

In the production of various steel structures, the flatness of the steel plate surface directly affects the quality of subsequent welding and assembly. Flattening is a necessary step to ensure the quality of steel structures.

On-site steel structure installation requires prefabricated steel components to be flattened to ensure that the weld seam gap meets the requirements, the installation dimensions are accurate, and the installation process is smooth.

Steel plates for ship hulls require high flatness and surface quality. Fine flattening of steel plates before ship assembly and welding is particularly critical.

Automobile bodies and internal structures use a lot of steel plates, which need to be accurately flattened to ensure appearance quality and structural strength. Steel plate flattening is an important automotive CNC machining method.

Many large household appliances shells such as refrigerators and washing machines use steel plates. Flattening can make the shells flatter and more beautiful.

The enclosures for medical and measuring devices require high-flatness steel plates. Flattening is the basis for ensuring their precision and stability.

The specific process of CNC steel plate flattening includes:

According to the original surface shape and deformation of the steel plate, design the machining program for the CNC machine tool.

Use a robot arm or manually clamp the steel plate onto the worktable of the CNC machine tool for fixing.

Clean the surface of the steel plate to remove dirt, grease, etc.

Start the CNC milling machine, load the program, and automatically perform planing machining to gradually flatten the surface of the steel plate.

Use measuring instruments to monitor the flatness of the steel plate, and manually intervene or modify the program if necessary.

Use a polishing device or polishing tool to polish the steel plate to improve the surface texture.

After passing the inspection, perform subsequent identification, packaging and other operations to complete the flattening process.

A: CNC milling machines can perform multi-axis machining, and precisely control each machining parameter through programming to achieve micrometer-level high precision flattening.

A: Although automated CNC flattening requires initial equipment investment, it can greatly reduce labor costs and improve efficiency. Overall, it has significant price advantages.

A: Slight polishing can further improve the surface texture, but excessive polishing will actually reduce surface accuracy. The extent needs to be properly controlled.

By using CNC milling machines and other automated flattening methods, high precision can be ensured while greatly improving the efficiency of steel plate machining. It is an effective means to achieve high quality and efficient steel plate machining, and is worth widespread application.

The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view

The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view Unveiling Precision: Mastering Surface Profile for Engineering ExcellenceNovember 21, 2023Engineering precision is more than a requirement; it's a commitment to excellence. Amidst the intricate world of engineering, understanding the nuances of surface profile becomes paramount.view

Unveiling Precision: Mastering Surface Profile for Engineering ExcellenceNovember 21, 2023Engineering precision is more than a requirement; it's a commitment to excellence. Amidst the intricate world of engineering, understanding the nuances of surface profile becomes paramount.view CNC Machine vs 3D Printer: A Comprehensive ComparisonNovember 6, 2023As the proud owner of Richconn, a CNC machining service provider, I understand the importance of choosing the right manufacturing technology for your production needs. The decision between CNC machines and 3D printers can be a daunting one, and that's why I'm here to provide you with a comprehensive comparison to help you make an informed choice.view

CNC Machine vs 3D Printer: A Comprehensive ComparisonNovember 6, 2023As the proud owner of Richconn, a CNC machining service provider, I understand the importance of choosing the right manufacturing technology for your production needs. The decision between CNC machines and 3D printers can be a daunting one, and that's why I'm here to provide you with a comprehensive comparison to help you make an informed choice.view Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view

Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view

Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view Revolutionizing Automotive Manufacturing with CNC Cutting Aluminum SheetsFebruary 29, 2024The Rise of CNC Cutting in Automotive ManufacturingIn the fast-paced world of automotive manufacturing, precision and efficiency are key factors that can make or break a company's success. One tec...view

Revolutionizing Automotive Manufacturing with CNC Cutting Aluminum SheetsFebruary 29, 2024The Rise of CNC Cutting in Automotive ManufacturingIn the fast-paced world of automotive manufacturing, precision and efficiency are key factors that can make or break a company's success. One tec...view

EN

EN

ru

ru