The high precision of molded products, the wide range of materials, and the short production cycle make it a popular choice for production and processing in the industrial sector.

* 16 years of SLS 3D printing experience

* 24*7 hour customer service

* Complete parts production within 24 hours at the fastest

* Certified to ISO9001, SO14001, IATF16949 and ISO27001

The high precision of molded products, the wide range of materials, and the short production cycle make it a popular choice for production and processing in the industrial sector.

3D printing technology breaks through the tradition and realizes integrated design and manufacturing. Complex geometries can be constructed more easily and at no additional cost.

SLS printing technology enhances the project process by producing functional end-use parts on demand.

Compared to traditional molding methods, SLS 3D printing technology can produce parts without the need to open a mold, eliminating the time required to open a mold and significantly increasing manufacturing efficiency.

Similar to the SLA light curing process (resin printing), you need to use a laser to cure the entire substance. The difference is that the SLS printing process uses an infrared laser beam and the material is changed from photosensitive resins to those composites such as plastics, waxes, ceramics, metal powders or nylon powders. First, very thin (sub-millimeter) layers of raw material powder are not dispersed on the table, then the computer-controlled laser beam is scanned by a 3D scanner and the two-dimensional data is layered at specific speeds and energy densities, with the laser-scanned powder being sintered into a solid layer of a certain thickness, while the unscanned areas are loose powder.

The powder is preheated to a temperature slightly below the melting point and then flattened using a roller or scraper. Under computer control, a high-intensity CO2 laser selectively sinter parts based on layered cross-section information, adhering to the molded part below and sintering the next layer as it is completed. When all sintering is complete, excess powder can be removed and the sintered part is available.

* Verification of functional testing, such as prototyping of exterior or R&D designs;

* Small batch customization/personalization, including 3D printing of customized gifts;

* For industries requiring precision and complex mechanisms, such as aerospace, medical, mold and die, and precision parts manufacturing.

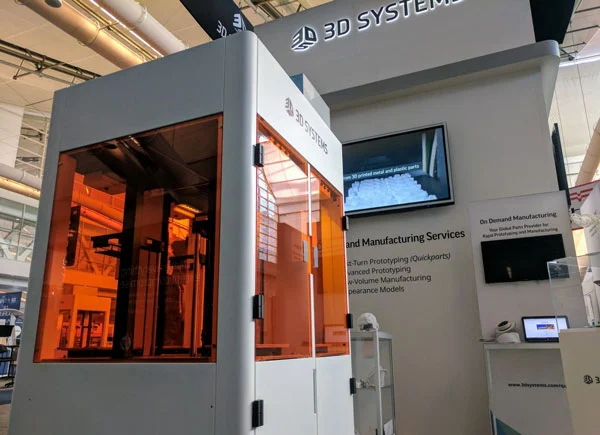

Richconn is a one-stop shop for selective laser sintering services, providing our customers with high-precision and high-performance 3D parts. Our engineers are experienced in SLS technology and can optimize your designs through CAD and handle SLS projects with a wide range of materials and applications. Our use of industry-leading SLS printers not only guarantees the quality of our products but also significantly increases productivity beyond just prototypes, but also for high volumes.

We offer instant quotes and feedback on your selective laser sintering project, we can manufacture 3D parts as fast as 1 working day, and our professional and friendly sales team are online 24/7 to ensure you are satisfied with the service you receive. We have obtained certifications including ISO9001, ROHS Directive, BSCI, and UL, and our SLS process and 3D parts meet international standards.

EN

EN

ru

ru