Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a disadvantage in the economy. Researchers at Florida International University have found a fast and effective low-temperature titanium alloy processing method, which reduces the heat required by 50%, which provides greater potential for the research of new titanium matrix composites.

Using the manufacturing method of powder metallurgy, the researchers applied the environment of low temperature (up to 650 ℃) and high pressure (up to 555 MPa) simultaneously in spark plasma sintering (SPS), and finally obtained the high-density parts, which are similar to the titanium alloy parts treated at high temperature in mechanical properties and structural functions. This finding is attributed to the "high pressure-assisted mass transfer and induced plastic deformation mechanism" in the alloy processing process. Through electron microscope observation, the researchers found that at low temperatures, the pressure on the alloy powder particles exceeded its plastic limit and promoted its densification.

Titanium matrix composites are considered to be more favorable for processing at low temperatures. This research result not only provides an alternative method for high-temperature titanium processing but also provides favorable conditions for the development of titanium matrix composites.

Carbon Steel: Types, Properties, and UsesDecember 8, 2023Carbon steel is one of the most common and widely used materials in the world, thanks to its low cost, high strength, and versatility.view

Carbon Steel: Types, Properties, and UsesDecember 8, 2023Carbon steel is one of the most common and widely used materials in the world, thanks to its low cost, high strength, and versatility.view How to Access Shaft Bearing and Housing Fit?May 23, 2024By describing the types of shafts, the steps for determining shaft fits, and other aspects of this article, the reader can gain a detailed understanding of how to determine bearing shaft and housing fits.view

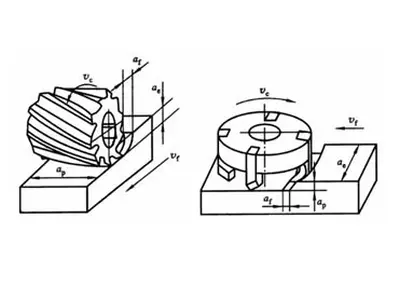

How to Access Shaft Bearing and Housing Fit?May 23, 2024By describing the types of shafts, the steps for determining shaft fits, and other aspects of this article, the reader can gain a detailed understanding of how to determine bearing shaft and housing fits.view Process Analysis of CNC MachiningAugust 10, 2022CNC machining refers to the processing that the control system issues commands to make the tool perform various movements that meet the requirements, and express the shape and size of the workpiece in...view

Process Analysis of CNC MachiningAugust 10, 2022CNC machining refers to the processing that the control system issues commands to make the tool perform various movements that meet the requirements, and express the shape and size of the workpiece in...view Top 6 Types of Rivets and Their Common UsesAugust 11, 2023Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and d...view

Top 6 Types of Rivets and Their Common UsesAugust 11, 2023Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and d...view Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view

Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view

Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view

EN

EN

ru

ru