Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, explaining how two-tone is achieved from multiple angles, providing cutting-edge experiences and authoritative information to help you understand everything about two-tone baked paint. In another article we will introduce the two-tone electroplating process.

Two-tone baked paint is a unique parts painting technique that is gradually gaining attention in the automotive and custom parts fields. By covering the part surface with two different colored paints and baking to form an excellent appearance. This technology can give parts a unique visual effect and higher durability, enhancing the connotation and value of the product. This article will explain in detail the steps and skills to achieve two-tone baked paint, as well as the advantages and precautions of this technology.

Compared with single color painting, two-tone baked paint can make the part surface show two different colors, achieving a richer sense of visual hierarchy. This not only makes the product appearance more stylish and technological, but also meets more consumers' personalized preferences. In addition, two-tone baked paint can also serve as a business marketing tool, attracting eyeballs and enhancing its value through unique painting.

Spray different areas of the parts with different colors according to the color requirements, and use baffles or shields for relevant segmentation. This process is operated before the paint dries, which requires precise shielding and spraying control technology.

First spray one color on the workpiece surface and bake once. After curing, mask the first sprayed surface, spray the second color and bake again. This requires strict control of the baking parameters.

Use gradient colors in the intersection of the two colors to achieve a smooth and natural transition. This requires dedicated gradient color spraying technology.

Coding equipment can directly spray patterns of two or more colors on the part surface. This technology is flexible and convenient to operate.

Cover different colored films on the cured base color to achieve a two-tone effect. This requires high-quality films with good surface processing.

Realizing two-tone baked paint requires a series of careful steps and professional techniques. The specific implementation process is as follows:

Before starting a two-tone baked paint project, you first need to clarify your design plan and choose suitable color combinations. You can choose colors that form a striking contrast, or more harmonious tones. It is important to ensure that the design scheme matches the purpose and style of the parts and adds unique charm.

Before spraying, it must be ensured that the part surface is clean, flat and free of any impurities. Thoroughly clean the parts, removing oil, dirt and old paint. Gently sand the part surface with appropriate sandpaper to ensure the paint layer adheres more firmly.

Shielding and Protection

Before spraying, it is necessary to carefully shield and protect each area of the parts to prevent unnecessary overspray. Use professional masking tape and plastic film to protect areas that do not need to be painted, ensuring that the paint is only sprayed in the designated area.

The first step is to apply primer. Choose one of the colors and spray evenly on the part surface, ensuring a thin and uniform coating. Use high-quality spray equipment and techniques to ensure optimal results.

After applying the primer, the parts need to be placed in a professional baking room to allow the paint layer to dry and cure quickly. The baking time and temperature should be determined according to the paint used and the material of the parts to ensure the coating achieves the best effect.

After coating the primer, it is necessary to mask and protect the completed areas for spraying the second color. Use tape and plastic film to protect the primer, ensuring that the new paint only covers the designated area.

After the first sprayed area is masked, you can start spraying the second color paint. Use the same method as coating the primer to spray the second color evenly. Ensure a smooth and natural transition, avoiding unclear color boundaries.

Similar to the first color paint, the second color paint also needs to be baked to ensure coating curing and durability. Place the parts in the baking room and bake according to the manufacturer's recommendations for the paint.

After all spraying is complete, applying a layer of high-quality clear coat is critical to ensuring the durability of the two-tone baked paint. Clear coat not only protects the painted surface, but also adds gloss and depth.

The final step is fine grinding and polishing of the parts. Remove possible flaws and sanding marks to add a smoother effect to the two-tone baked paint surface.

The adhesion between color layers cannot be too high or too low, otherwise it will easily peel off or mix colors.

The transition of the color boundary must be smooth and natural to prevent obvious boundaries.

The baking equipment needs to precisely control the time and temperature parameters.

The two-color layers should be equally thick to prevent uneven appearance.

The color difference needs to be controlled within an acceptable range.

In summary, two-tone baked paint can greatly enhance the appearance and added value of products. By choosing a suitable two-tone baked paint method according to the product characteristics and controlling key quality parameters, the desired two-tone baked paint effect can be obtained.

Unique visual effect: Two-tone baked paint brings striking contrasting colors to the parts, making them stand out from many products, attracting more attention.

High durability: After professional spraying and baking, the two-tone baked paint coating is more solid and durable, able to maintain good appearance for a long time.

High customizability: Two-tone baked paint can be customized according to customer requirements to meet the special needs and style requirements of different parts.

Enhanced quality: Two-tone baked paint gives the parts a higher texture and sophistication, making it look more high-end in the overall product experience.

Choose suitable paint: Before achieving two-tone baked paint, compatible paints must be selected to ensure a smooth transition between the two colors.

Professional technical requirements: Two-tone baked paint is a complex technical activity that needs to be operated by professional painters to ensure effect and quality.

Precise control of color boundaries: During spraying of different colors, color boundaries must be precisely controlled to avoid color confusion and blurring.

Strict environmental requirements: The spraying process needs to be carried out in a professional spray room to ensure a clean environment and prevent dust and impurities from entering the paint layer.

The time required to achieve two-tone baked paint depends on the size and complexity of the parts and the skill level of the painter. Generally, a two-tone baked paint project takes several days to a week to complete.

Professionally done two-tone baked paint does not negatively affect the quality of parts. On the contrary, it can enhance the texture and appearance of parts and increase their value.

Two-tone baked paint is suitable for most types of parts, including automotive parts, furniture, crafts, etc. But for parts with special materials and shapes, professional evaluation is needed.

When maintaining parts with two-tone baked paint, avoid using corrosive and abrasive cleaners, regularly wipe the surface to keep it smooth, and avoid collisions and scratches.

Traditional painting usually uses only one color of paint, while two-tone baked paint uses two different colored paints and achieves the color transition effect through precise boundary control.

The cost of two-tone baked paint varies depending on factors such as project complexity, paint used, and painter fees. In general, two-tone baked paint is relatively expensive, but its uniqueness and high-quality feel make it worth investing in.

Two-tone baked paint is a unique parts painting technique that can give parts unique visual effects and higher durability. Through careful design and professional technology, implementing two-tone baked paint can add a lot of color to the product. However, to get the best results, it is recommended to entrust professional painters to operate.

The above technologies are the knowledge accumulated by our engineers over the years, and the services we can provide to you.

How to choose the right material for cnc cnc machining parts?November 1, 2023In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.view

How to choose the right material for cnc cnc machining parts?November 1, 2023In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.view How to Reduce CNC CostsOctober 16, 2023In CNC machining, there are advances and improvements year after year. As a result, it is also becoming more complex. Consequently, it's also becoming more difficult to decide what to consider whe...view

How to Reduce CNC CostsOctober 16, 2023In CNC machining, there are advances and improvements year after year. As a result, it is also becoming more complex. Consequently, it's also becoming more difficult to decide what to consider whe...view Spot Welder 101: In-Depth Guide of Process and Tips RevealedJanuary 2, 2024What's a spot welder? The article gives you a comprehensive guide to spot welders and shows you how to control spot welders effectively.view

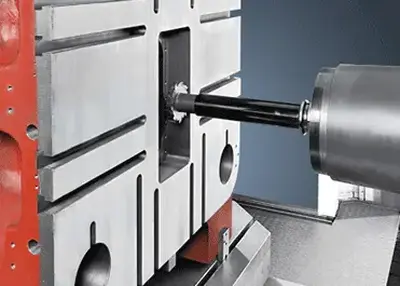

Spot Welder 101: In-Depth Guide of Process and Tips RevealedJanuary 2, 2024What's a spot welder? The article gives you a comprehensive guide to spot welders and shows you how to control spot welders effectively.view Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view

Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view Machined Washers: Everything You Need to Know About CNC-Engineered FastenersNovember 8, 2023Welcome to the world of machined washers! If you're reading this, you're about to embark on a journey to discover the fundamental building blocks of precision engineering. Whether you're an engineer, a DIY enthusiast, or a professional seeking the perfect fastener for your project, this comprehensive guide will equip you with the knowledge to make informed decisions and take your projects to the next level.view

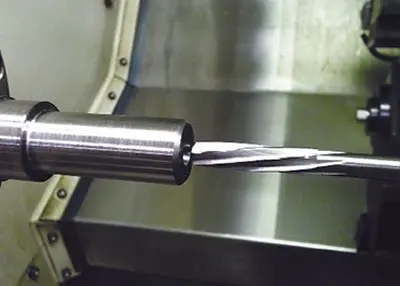

Machined Washers: Everything You Need to Know About CNC-Engineered FastenersNovember 8, 2023Welcome to the world of machined washers! If you're reading this, you're about to embark on a journey to discover the fundamental building blocks of precision engineering. Whether you're an engineer, a DIY enthusiast, or a professional seeking the perfect fastener for your project, this comprehensive guide will equip you with the knowledge to make informed decisions and take your projects to the next level.view Turning Cylindrical PartsOctober 16, 2023In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.view

Turning Cylindrical PartsOctober 16, 2023In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.view

EN

EN

ru

ru