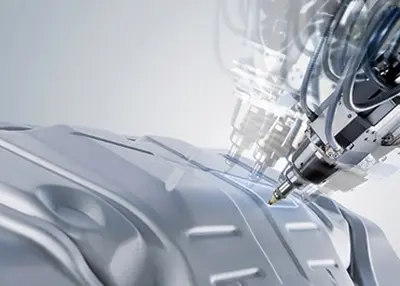

The demand for faster and more precise fabrication of products in the ever-evolving market has led to the emergence of CNC machine shops. These shops result from the industrial revolution, constantly upgrading and investing in technologies to ensure optimal manufacturing efficiency. They offer CNC machining services for various businesses and applications. This comprehensive guide provides detailed information on CNC machine shops.

A CNC machine shop refers to a specific location or building where CNC machining processes take place. It can exist as an independent facility or be a designated area within a larger factory, having the primary purpose of fulfilling the requirements and desires of customers. Inside the shop, there are a variety of CNC machines that are utilized to carry out subtractive techniques in order to fabricate both simple and intricate parts.

This machine shop employs a range of materials, such as plastics, metals, composites, and wood, to create diverse custom parts through different machining methods. Numerous industries heavily rely on CNC machine shops, including but not limited to the automotive, aerospace, medical, and military sectors, as they offer extensive capabilities for manufacturing according to immediate demands.

In a CNC machine shop, you will typically find various types of equipment and machinery that are used for precision machining and manufacturing. Some common equipment you will find include:

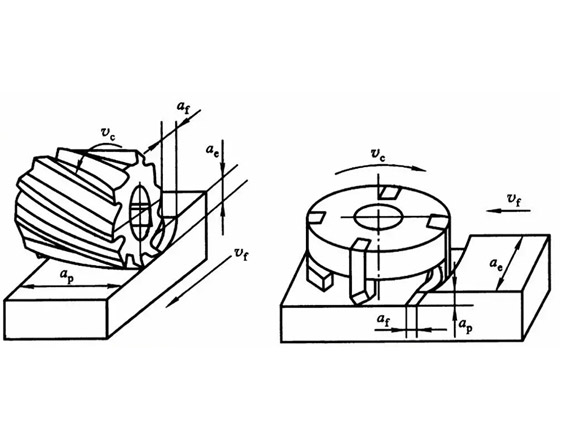

Milling in CNC machining is cutting away part of a workpiece using rotating cutting tools.

CNC Milling machines are used in various industries like automotive, aerospace, and medical devices to create different shapes or products using a rotatory cutting tool. The workpiece remains still while the cutting tool moves around it based on a computer program to remove material and create precise cuts and shapes. The machine can be programmed to make multiple passes to achieve the desired final product.

At Richconn, for instance, we are proud of our extensive CNC machining capabilities, driven by 30 CNC milling machines with a processing capacity of 100,000 pieces per year.

2. CNC Lathe Machine

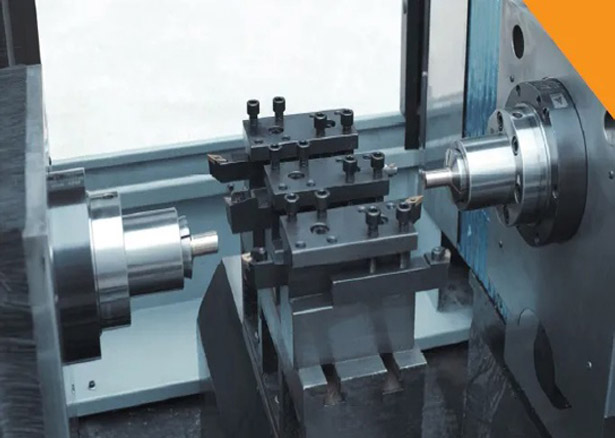

Typically, a lathe is operated manually by a skilled operator. However, in a CNC machining shop, CNC lathes are commonly used. These machines function in the opposite way to milling machines. In a lathe, the workpiece material rotates while the cutting tool moves around the workpiece in a linear pattern to make specific cuts. CNC lathes are frequently employed for tasks such as grooving, facing, knurling, and sanding. CNC lathes offer several advantages over traditional manual turning, such as improved consistency, repeatability, and efficiency.

At Richconn, We have 50 CNC automatic lathes with a processing capability of one million pieces per year. We have digital lathe processing with high precision (0.002).

3. Grinding Machine

A grinding machine utilizes a high-quality grinding abrasive wheel composed of small, hard particles to remove thin layers of material and achieve precise dimensions with excellent or mirror-like surface finishes. These operations are suitable for high-precision parts and are recommended for tight tolerances. They tend to be expensive and time-consuming.

4. Drill Press

A drill press is a fixed-mounted type of drill that offers precise movements and is often operated using a lever. It provides more stability and power compared to handheld drills. Although the drill press functions similarly to a regular press, it can be used for various manufacturing operations beyond drilling holes.

CNC machining companies provide numerous advantages to diverse organizations. Here are some of these benefits:

Increased Accuracy and Precision

CNC machines in a machine shop offer exceptional accuracy and precision in manufacturing processes. Computer-controlled operations eliminate human error and ensure consistent results, resulting in high-quality and precise products.

Accomplished Higher Productivity

CNC machines are designed to automate and streamline manufacturing processes, leading to significantly faster production speeds compared to manual operations. This allows for higher productivity and shorter lead times.

Reduced Labor Expenses

By using CNC machines, a machine shop can reduce its reliance on manual labor. The automation provided by these machines reduces the need for a large workforce, resulting in cost savings on labor expenses.

Ensured Consistent and Uniform production

CNC machines are programmed with detailed instructions, ensuring consistent and uniform production. This leads to products with identical dimensions, finishes, and quality, which is particularly important in industries where consistency is critical.

Although CNC machine shops provide several benefits to enterprises, a few difficulties may impede their performance. Here are some of these difficulties:

1. High Initial Investment Costs

Setting up a CNC machine shop requires a significant initial investment. CNC machines are expensive, and acquiring a range of machines for various operations can be financially challenging for small businesses. Additionally, there are costs associated with purchasing or leasing a suitable facility, obtaining necessary permits, and acquiring the required software and tools. If you don’t want to spend much money on a CNC machining shop, you could choose Richconn as your best partner. Richconn is an experienced CNC machining service that specializes in machining metal parts. We have delivered parts to thousands of customers around the world.

2. Shortage of Skilled Labor

Operating CNC machines requires specialized knowledge and skills. Finding and retaining skilled operators who can effectively program and operate these machines can be a challenge. The shortage of trained CNC machinists in the job market can make it difficult for machine shops to build a competent workforce. Richconn, a reliable CNC machine shop, will help you solve these problems. We have a skilled team of CNC machining experts who will ensure your products come out the right way. Our team of highly trained quality control experts, engineers, and designers ensure that all CNC machined produced parts by the company meets and surpasses industry standard in durability and functionality.

3. Maintenance and Upkeep Expenses

CNC machines require regular maintenance and upkeep to ensure their optimal performance. This includes routine inspections, repairs, and the replacement of worn-out parts. These associated costs can add up over time and impact the overall profitability of the machine shop.

4. Stay Updated with Technological Changes

CNC technology is constantly evolving, with new software and hardware advancements being introduced regularly. Keeping up with these technological changes can be demanding and expensive. To remain competitive, CNC machine shop owners need to invest in continuous training for their staff, upgrade their equipment and software, and adapt their processes to incorporate the latest advancements.

By the end of the article, I believe you should have known everything about the CNC machining shop. In addition, you could choose the best CNC machining shop to work with like Richconn. It provides a wide range of CNC machining solutions such as CNC milling services, CNC turning, and surface finishing. Find CNC shops near me! Get in touch with us today or get an automatic quote for your production needs.

Drill and Tap Specification ChartNovember 17, 2023In CNC machining, the usual process is to use a drill bit to drill a hole in the workpiece and then use a tap of the appropriate size to cut the desired threads in the hole. This ensures that the threads match the design requirements and can ensure that the threads fit correctly with other components.view

Drill and Tap Specification ChartNovember 17, 2023In CNC machining, the usual process is to use a drill bit to drill a hole in the workpiece and then use a tap of the appropriate size to cut the desired threads in the hole. This ensures that the threads match the design requirements and can ensure that the threads fit correctly with other components.view CNC Machined Motorcycle Parts: Precision Craftsmanship by RichconnNovember 14, 2023Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!view

CNC Machined Motorcycle Parts: Precision Craftsmanship by RichconnNovember 14, 2023Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!view Precautions for Using CNC TurningApril 25, 2023Turning is a cutting method that uses the rotation of the workpiece relative to the tool on a lathe to perform cutting operations. CNC turning allows the workpiece rather than the tool to provide most...view

Precautions for Using CNC TurningApril 25, 2023Turning is a cutting method that uses the rotation of the workpiece relative to the tool on a lathe to perform cutting operations. CNC turning allows the workpiece rather than the tool to provide most...view Machining on a Dime: Creating High-Quality Products with Cheap CNC MaterialsDecember 4, 2023In today's fast-paced world, businesses are constantly seeking ways to reduce costs without compromising on quality. This is particularly true for manufacturers who heavily rely on CNC machining t...view

Machining on a Dime: Creating High-Quality Products with Cheap CNC MaterialsDecember 4, 2023In today's fast-paced world, businesses are constantly seeking ways to reduce costs without compromising on quality. This is particularly true for manufacturers who heavily rely on CNC machining t...view What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view

What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view Spot Welder 101: In-Depth Guide of Process and Tips RevealedJanuary 2, 2024What's a spot welder? The article gives you a comprehensive guide to spot welders and shows you how to control spot welders effectively.view

Spot Welder 101: In-Depth Guide of Process and Tips RevealedJanuary 2, 2024What's a spot welder? The article gives you a comprehensive guide to spot welders and shows you how to control spot welders effectively.view

EN

EN

ru

ru