Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.

The same "brittleness in cold" phenomenon occurs with many polymers - drop your polypropylene (PP) recycling container in the middle of winter, and you'll probably need a new one. Other plastics, such as polyetheretherketone (PEEK), can be used at almost any temperature, and still others (quite a few, in fact) gradually become brittle when exposed to UV light. An example of this is the otherwise tough polyoxymethylene (POM), also known as acetal, which goes limp when exposed to sunlight for too long, as does one of the most impact-resistant polymers of all, polycarbonate (PC).

Because of these variables, it's important to evaluate material options before beginning a project and select those that will work well in the product's intended environment. One way to start is to review the plastics manufacturer's data sheets. There you will find terms such as "Izod impact strength," "Gardner impact strength" and "Instrumented puncture resistance." Each of these is defined in various ASTM and ISO standards [1](e.g., the ISO 179 Charpy notched impact test or the ASTM D3763 multiaxial puncture test)[2] and attempts to describe how materials react when struck.

The basic idea is to strike a sample of a particular material under controlled conditions and see how it withstands the impact. The IZOD notch test uses a pendulum that swings down and strikes a fixture that hits the plastic. The Gardner test uses a weight that falls vertically on a round, arrow-like object that sits on top of the material. The weight and height required to cause damage determine impact strength. Ultimately, the greater the impact required to break a plastic, the higher its impact strength.

Plastic pellets are placed in a hopper to be melted into an injection molded part.

Given the many standards, your design department should determine which standards it will use in product development so you can make a direct comparison. Unfortunately, the variety of standards can be confusing because each refers to different test procedures and methods for preparing test samples. Data sheet specifications vary, and the vexing problem of metric or imperial units keeps cropping up as well. Some data sheets do not include values for notched bar impact tests, but give values for tensile modulus, flexural strength, elongation at yield, and hardness, which at least give an indication of the strength of the material. Note, however, that strength and toughness are often at odds with each other - higher strength usually means a higher degree of brittleness, the exact opposite of impact toughness.

Much of a polymer's strength or toughness depends on its glass transition temperature (Tg) and whether the plastic is amorphous or semi-crystalline. There is no room for all of these issues at this point, but we do have another design tip that explains this important topic. Check it out if you want to understand the subject better.

Check it out if you want to understand the topic better.

So what is the answer? There's actually more than one. If your company has invested in finite element analysis (FEA) software, then congratulations are in order. With good software, you can upload different materials and their properties, select variables such as temperature and load, and then hit virtual parts with virtual hammers to see how they react. But even without high-end engineering software, SOLIDWORKS, Fusion 360, and other popular CAD packages offer built-in FEA capabilities or FEA add-ons at a reasonable price.

So here are "five impact-resistant materials" as promised at the beginning of this design tip. This is by no means a comprehensive list, and as mentioned earlier, toughness depends on many factors, not the least of which is part geometry.

Unlike most amorphous polymers, acrylonitrile butadiene styrene (ABS) is opaque. It is also very tough and impact resistant, even at low temperatures. Your car's dashboard might be made of ABS, as are the 9036 Lego bricks in that model of the Roman Colosseum you've been working on for the past three weekends. ABS is both hard and rigid, electrically insulating, extremely malleable, and can be recycled over and over again. However, it cannot tolerate solvents, prolonged exposure to the sun, or applications where high fatigue strength is required. As for the next material, we can machine, custom 3D printing and injection mold ABS and ABS-like materials.

Polycarbonate (PC), the material for bulletproof glass, is particularly impact resistant. Think of it as the yin to the hard, scratch-resistant yang of acrylic. PC withstands repeated steam sterilization, so it's often used in medical applications. When properly treated, it is also heat, flame and UV resistant, making it a top choice for any application involving greenhouses, safety glasses, headlight bezels or protective shields. Note, however, that PC is one of the more expensive engineering polymers and should be coated to prevent scratching when optical transparency is a concern.

Some manufacturers claim that rigid polyethylene (HDPE) is not only the most versatile of all plastics, but also the most widely used. They are probably right about that. HDPE comes in rigid or flexible forms and is lightweight yet strong. Automakers use it for gasoline tanks, dairy companies use it for milk containers, and outdoor furniture manufacturers use it for - well - outdoor furniture. Each of these applications requires good impact resistance, and just as with exposure to sunlight and chemicals, HDPE meets those requirements.

Pellets of durable, lightweight polycarbonate thermoplastic can be molded into parts that are highly impact and fracture resistant.

It not only has very high impact strength, but also has very good thermal stability. 500-GA20 is a high melt index impact copolymer for injection molding. Applications include household goods, containers, car batteries, toys, compounds and consumer products.

This last example might surprise you. PTFE, also known as polytetrafluoroethylene, also known as Teflon, is soft and pliable but exceptionally tough. Its impact strength is better than that of PEEK and most polycarbonates, and is equivalent to that of HDPE. It also has a very low coefficient of friction, rivaled only by diamond-like carbon (DLC) and the super-hard ceramic If you're looking for injection-molded or 3D-printed Teflon parts, read on - thanks to its very high melting point of 327 °C [1](621 °F)[2], PTFE can be CNC machined, but that's about it. Note, however, that it tends to creep under pressure, so it should be mechanically fixed when used for washers, bearings and other load-bearing applications.

There is also polyphenylsulfone (PPSU), PEEK, TPE or thermoplastic elastomer, and even some nylons and acetals. Again, impact strength often depends on the application temperature and is mitigated by tensile strength, UV resistance and other factors. Don't hesitate to make some sample parts and compare them before deciding on one material or another.

Before we conclude, there is one last point, and it is perhaps the most important of all: The role of product design in impact resistance. For example:

* Notches and sharp corners increase the likelihood that a part will break under force, while rounded corners tend to make parts more durable.

* If you use stiffening ribs, they should be placed in areas of compressive rather than tensile forces, just as welds should ideally run where potential impact forces are lowest.

* At the risk of sounding counterintuitive to an engineer, try to avoid rigid, very stiff product designs - a part that can flex a little under pressure is less likely to fail.

Finally, be sure to share any concerns you have with us during the bidding phase. We have decades of manufacturing experience to help you find the right material and design for your success.

Building Effective Partnerships For Manufacturing StartupsOctober 10, 2023You might have a great idea that leads you to launch a startup. But then you realize you can’t handle it all on your own. You need professional advice, help, and often financial resources.view

Building Effective Partnerships For Manufacturing StartupsOctober 10, 2023You might have a great idea that leads you to launch a startup. But then you realize you can’t handle it all on your own. You need professional advice, help, and often financial resources.view Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view

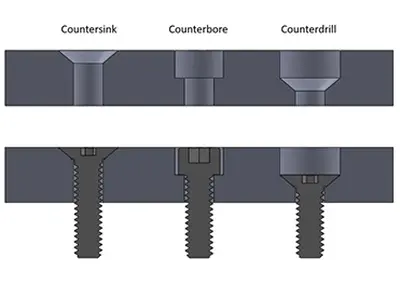

Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view

What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view

CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view CNC Steel: Key to Precision in CNC MachiningNovember 6, 2023Are you seeking the perfect material for your CNC machining project, one that promises precision and durability? Look no further than CNC steel. In this guide, I'll take you through the world of CNC steel, helping you understand its various types, selection criteria, and how to make the most of this essential material in your CNC machining endeavors.view

CNC Steel: Key to Precision in CNC MachiningNovember 6, 2023Are you seeking the perfect material for your CNC machining project, one that promises precision and durability? Look no further than CNC steel. In this guide, I'll take you through the world of CNC steel, helping you understand its various types, selection criteria, and how to make the most of this essential material in your CNC machining endeavors.view Transparent Aluminum: A Revolutionary Material for the FutureDecember 6, 2023Transparent aluminum is a fascinating and futuristic material that has many advantages and disadvantages. It is a material that was first mentioned in the 1986 science fiction film Star Trek IV: The Voyage Home, where the crew of the USS Enterprise used it to construct a tank for transporting two humpback whales.view

Transparent Aluminum: A Revolutionary Material for the FutureDecember 6, 2023Transparent aluminum is a fascinating and futuristic material that has many advantages and disadvantages. It is a material that was first mentioned in the 1986 science fiction film Star Trek IV: The Voyage Home, where the crew of the USS Enterprise used it to construct a tank for transporting two humpback whales.view

EN

EN

ru

ru