Titanium and Aluminum are two excellent lightweight metals, and when it comes to machining, the choice of material is a crucial decision. Titanium and Aluminum are both common lightweight metal materials, and both have their own unique advantages in different situations. Let's take a deeper look at the differences between titanium and aluminum when it comes to machining.

When we compare the weights of titanium and aluminum, we need to consider their densities and uses. Titanium and aluminum are both common metals, and they have a wide range of applications in many industrial and manufacturing fields.

Density: approximately 4.5 g/cm3 (varies depending on temperature and alloy composition)

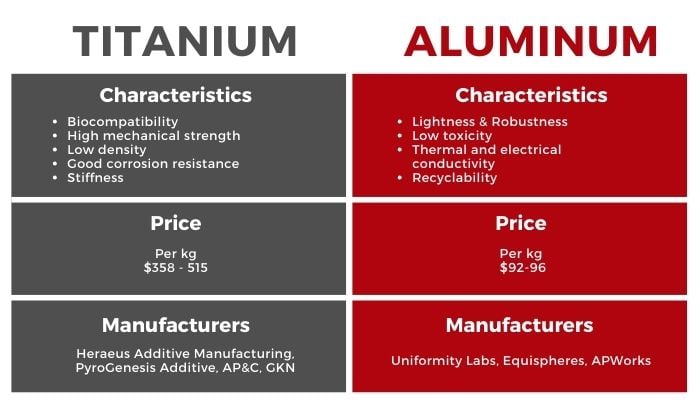

Characteristics: Titanium is a very strong and durable metal with excellent corrosion resistance and high strength.

Applications: Titanium is commonly used in aerospace, medical devices, chemical equipment, and automotive parts.

Density: approximately 2.7 g/cm3

Characteristics: Aluminum is a light, corrosion-resistant metal with good thermal conductivity and plasticity.

Applications: Aluminum is widely used in aerospace, automotive manufacturing, construction, electronics and other fields.

Now let's do a weight comparison to get a clearer picture of the differences between them.

Considering the density of titanium and aluminum, titanium is about 1.67 times denser than aluminum. This means that if we have the same volume of titanium and aluminum, titanium will weigh approximately 1.67 times more than aluminum.

For example, suppose we have one cubic meter of aluminum and one cubic meter of titanium. Based on the difference in density, the titanium will weigh about 1.67 times more than the aluminum. This means that titanium weighs more for the same volume of titanium and aluminum.

The strength comparison between aluminum and titanium is an important topic because the strength of a material is directly related to its performance and reliability in a variety of applications.

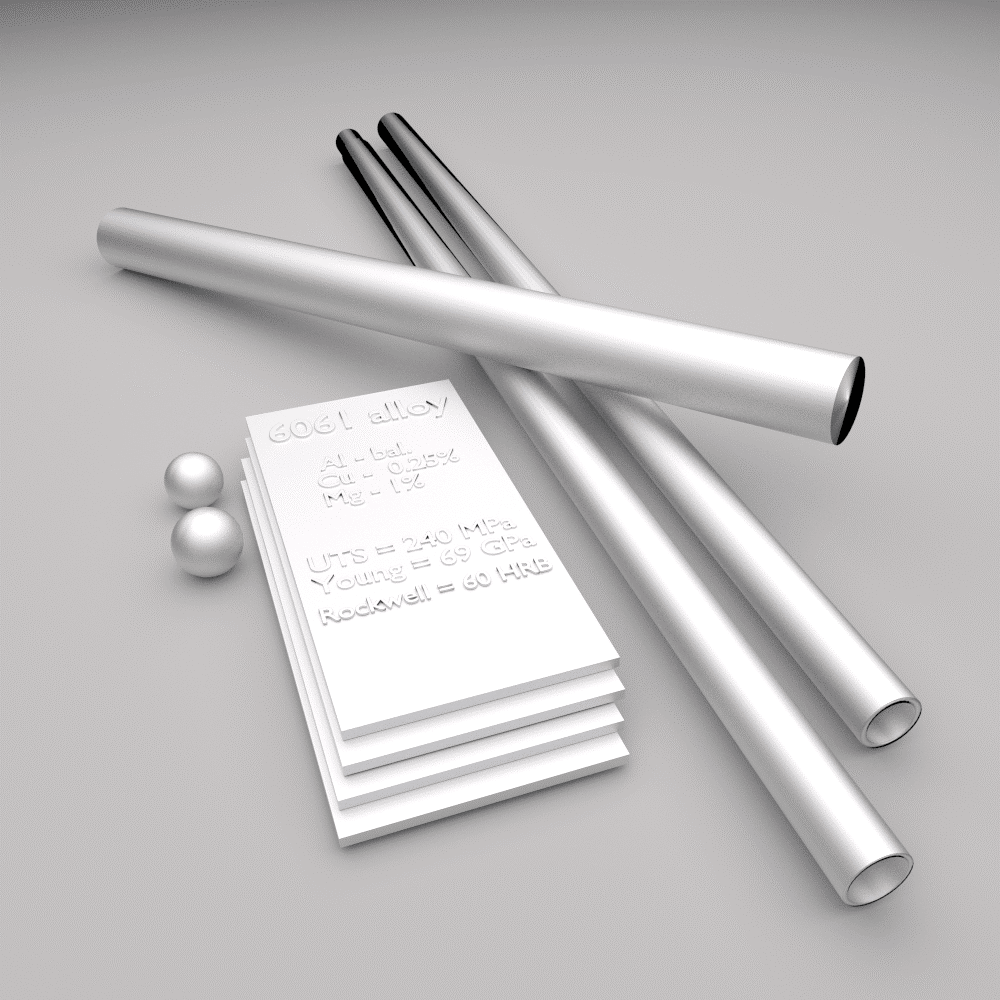

Aluminum is a lightweight metal that is typically less strong than titanium. The strength characteristics of aluminum include the following:

Tensile Strength: Aluminum's tensile strength typically ranges from 100 to 300 MPa, depending on the type of alloy and treatment. Compared to other metals, aluminum has a relatively low tensile strength.

Modulus of Elasticity: Aluminum has a modulus of elasticity of about 70 GPa, indicating a low relative stiffness.

Hardness: Aluminum generally has a low hardness, usually between 15 and 25 HB.

In contrast, titanium is usually superior to aluminum in terms of strength. It has the following properties:

Tensile Strength: Titanium's tensile strength is typically between 600 and 1000 MPa, depending on the type of alloy and heat treatment. This high strength makes titanium ideal for many high-strength applications.

Modulus of Elasticity: Titanium has a modulus of elasticity of approximately 110 GPa to 120 GPa, which is higher than that of aluminum, indicating a higher relative stiffness.

Hardness: Titanium is generally harder than aluminum, meaning it is more resistant to scratching and deformation.

On balance, titanium is usually superior to aluminum in terms of strength. It has a higher tensile strength and higher modulus of elasticity, which makes titanium more suitable for use in applications that require high strength and durability.

Comparing the cost of titanium versus aluminum is important because cost is one of the critical considerations in material selection.

Production Costs: Titanium is relatively expensive to produce. Titanium is a rare metal and its extraction and refining processes are relatively complex and require high levels of energy and process requirements, which results in higher production costs.

Processing costs: Titanium is also more difficult to process. Titanium has good corrosion resistance and high strength, but it is also a difficult material to process, requiring the use of special processes and equipment for processing, which increases the processing costs.

Price volatility: The price of titanium fluctuates significantly. The global titanium market is affected by a variety of factors such as the supply of raw materials, changes in demand, geopolitical factors, and so on, so the price of titanium is more volatile.

Production Costs: Aluminum is less expensive to produce than titanium. Aluminum is an abundant metal in the earth's crust, and the energy consumption in the extraction and refining process is relatively low, so its production cost is moderate.

Processing Costs: Aluminum is relatively easy to process. Aluminum has good plasticity and thermal conductivity, and can be easily machined into a variety of shapes, which reduces its processing costs.

Price Stability: The price of aluminum is relatively stable. Although it is subject to market supply and demand factors, aluminum is a common metal with relatively low price fluctuations.

Aluminum has relatively low production and processing costs and is relatively stable, compared to titanium, which is more expensive and more volatile.

In practical applications, cost considerations are very important. Despite its superior strength and corrosion resistance, titanium may be a necessary, albeit costly, choice in some high-end applications such as aerospace and medical device manufacturing. Aluminum, on the other hand, while less strong, is more cost effective and is widely used in automotive and construction applications.

The density of titanium vs. aluminum is one of the most important indicators of the physical properties of the two materials.

Average Density: The average density of titanium is about 4.5 g/cm3 . This means that for the same volume, titanium has a greater mass than the same volume of water or aluminum, since water has a density of about 1 g/cm3 and aluminum about 2.7 g/cm3.

Range of Variation: The density of titanium varies slightly depending on the alloy composition, manufacturing process, and temperature, but is usually around 4.5 g/cm3.

Application Impact: Titanium's relatively high density makes it heavier than aluminum. In some applications, such as aerospace, this may have an impact on total weight.

Average Density: Aluminum has an average density of approximately 2.7 g/cm3 . This makes aluminum a lightweight metal with a low density relative to many other metals.

Stability: Aluminum's density is relatively stable and is not affected by changes in temperature and pressure under normal conditions.

Application Impact: Aluminum has significant advantages in areas requiring lightweight design (e.g., automotive manufacturing, aerospace) due to its lightweight nature.

In terms of density, titanium is about 1.67 times denser than aluminum. This means that if you have the same volume of titanium and aluminum, titanium will weigh approximately 1.67 times as much as aluminum. This means that in some applications where weight requirements are sensitive, aluminum may be more suitable because it is relatively lightweight.

When talking about titanium and aluminum colors, they actually have different appearance and color characteristics. below is a simple table comparing titanium and aluminum colors:

| Feature | Titanium | Aluminum |

|---|---|---|

| Color | Titanium typically appears grayish-white or silver-gray. | Aluminum usually appears silvery-white or gray-silver. |

| Surface | It has a particulate luster. | It has a bright metallic luster. |

| Oxidation | Can form a metallic sheen oxide layer. | May form an aluminum oxide layer. |

| Appearance in Use | Typically appears smoother and more uniform. | Often exhibits more texture and material feel. |

| Corrosion Resistance | Titanium has excellent corrosion resistance. | Aluminum also has fairly good corrosion resistance. |

This table describes some of the main differences between titanium and aluminum in terms of color, surface characteristics, oxidation, appearance in use, and corrosion resistance. Titanium usually presents a grayish-white or silver-gray color with a particulate luster on its surface, while aluminum is typically silvery-white or gray-silver with a bright metallic luster. These characteristics offer distinct aesthetics and practicality in various applications and environments.

Durability is one of the most important factors in material selection and design considerations.

Excellent Corrosion Resistance: Titanium is known for its excellent corrosion resistance. It can withstand many chemicals and corrosive media, including seawater, acids, and alkalis. This makes titanium widely used in marine engineering, chemical equipment and other fields.

High Strength and Tensile Properties: Titanium has excellent strength and tensile properties, which allows it to maintain structural integrity when subjected to high pressures and temperatures, making it suitable for use in aerospace and high-end industries.

Fatigue Resistance: Titanium exhibits good fatigue resistance, with the ability to withstand cyclic stress and vibration over long periods of time, which makes it excellent in high frequency operating environments such as aero-engine components.

Excellent lightweight properties: Aluminum is a lightweight metal with a lower density compared to titanium, which makes it useful in a wide range of automotive and aerospace applications, reducing overall weight and improving fuel efficiency.

Good corrosion resistance: Aluminum is also quite resistant to corrosion and shows good durability in most environments, especially when an oxide layer is formed to prevent further corrosion.

Ease of Machining and Malleability: Aluminum is easy to machine into a variety of shapes and has excellent malleability, making it one of the preferred materials in manufacturing and construction.

From a durability standpoint, titanium excels in terms of corrosion resistance and strength for environments that require long-term resistance to corrosion, high intensity, and high temperatures. However, titanium is more expensive and difficult to process, which somewhat limits its widespread use.

Aluminum, on the other hand, is known for its light weight, corrosion resistance, and ease of machining, which makes it the primary choice for many industrial and everyday applications. Although it may not be as heat resistant or as strong as titanium in certain situations, its wide range of application scenarios make it one of the main materials used in manufacturing.

Hardness is one of the most important measures of a material's ability to resist scratches, deformation and wear.

Hardness Range: The hardness of titanium varies according to its alloy composition and heat treatment, and usually varies over a considerable range. Generally speaking, the hardness of pure titanium ranges from 150 to 250 Rockwell Hardness (HV).

SCRATCH RESISTANCE: Titanium is usually highly resistant to scratches, but is not completely scratch resistant. Its surface is relatively hard, but can still be scratched or damaged under certain conditions.

Abrasion Resistance: Despite its high hardness, pure titanium has relatively average abrasion resistance, so other coatings or alloying methods may need to be considered to increase its surface hardness where higher abrasion resistance is required.

Hardness Range: Aluminum's hardness generally ranges from 15 to 100 Rockwell hardness (HV), depending on its alloying composition and processing condition. Comparatively speaking, the hardness of aluminum is usually low.

Scratch Resistance: Aluminum has a relatively soft surface that can be easily scratched or marked, especially in its pure form.

Abrasion Resistance: Aluminum is generally resistant to abrasion and its relatively soft surface may wear out with prolonged use or under friction conditions.

From a hardness standpoint, titanium is generally harder than aluminum, relatively speaking. Titanium typically performs better in terms of surface hardness and has higher scratch resistance.

Scratch resistance is a key material property, especially in areas involving exterior surfaces and structures, such as automotive, aircraft, construction, and various equipment manufacturing.

Effect of hardness: Titanium has a relatively high hardness, which makes it somewhat more resistant to scratching. Hardness is an important indicator of a material's resistance to surface scratching and wear.

Oxide Protection: The oxide layer formed on the surface of titanium contributes to its scratch resistance. This oxide layer can form in a number of environments, creating a protective layer that makes titanium surfaces resistant to some degree of scratching.

Corrosion Resistance: Titanium's excellent resistance to corrosion also helps maintain its appearance, as corrosion and oxidation can lead to scratching and abrasion of the surface.

Lower Hardness: Comparatively speaking, aluminum has a lower hardness. This means that in some cases, aluminum surfaces may be more susceptible to scratching and abrasion.

Surface treatment: Aluminum is often treated with a surface treatment, such as anodizing, which creates a harder oxide layer and improves its scratch resistance. This treatment also helps prevent corrosion.

Lightweight Design: Aluminum is widely used in some applications due to its lightweight design, but this can also result in a relatively thin surface and susceptibility to scratching.

Titanium may have some advantages over aluminum when it comes to scratch resistance, primarily in terms of its higher hardness and the formation of an oxide layer. However, this is not to say that aluminum has no advantage in this area. Aluminum can be surface treated and alloyed to increase its hardness, improve scratch resistance, and is preferred in some cases due to its lightweight design.

Thermal conductivity is an important measure of a material's ability to conduct heat and is critical for heat transfer applications in engineering and manufacturing.

Thermal Conductivity: Titanium has a thermal conductivity of approximately 21-23 Watts/(m-Kelvin), which puts it in the category of metals with moderate thermal conductivity in general. In relative terms, titanium has moderate thermal conductivity.

Temperature Dependence: The thermal conductivity of titanium usually varies at different temperatures. In general, the thermal conductivity increases slightly with increasing temperature, but the change is not very drastic.

Areas of Application: Titanium's thermal conductivity makes it relatively suitable for use in some high temperature environments, such as aircraft engine components. However, compared to some other metals, such as copper and aluminum, titanium's thermal conductivity is not particularly impressive.

Thermal Conductivity: Aluminum has a thermal conductivity of about 200 watts/(m-koi), which is much higher than that of titanium. Aluminum is a very good thermal conductor, and its thermal conductivity is among the higher levels of common metals.

Temperature Dependence: Aluminum's thermal conductivity also varies slightly with temperature, but relatively little. Overall, aluminum has good thermal conductivity at all temperatures.

Areas of application: Aluminum's superior thermal conductivity has led to a wide range of applications in heat dissipation and thermal conductivity. Aluminum is often chosen for electronic equipment, automotive radiators, kitchen appliances, and other areas to conduct and disperse heat efficiently.

Overall, aluminum is significantly better than titanium in terms of thermal conductivity. Aluminum's high thermal conductivity makes it the material of choice for many applications that require superior thermal performance, especially where heat needs to be conducted and dispersed effectively. Titanium, by contrast, has more moderate thermal conductivity and is better suited for specialized applications in high-temperature environments.

Aluminum is an ideal choice in scenarios where high thermal conductivity is required, such as in electronic equipment, to ensure that the equipment can quickly dissipate the heat generated. However, in some high temperature and corrosive environments, titanium may be more suitable due to its excellent corrosion resistance and relatively high melting point.

Titanium and aluminum are two metallic materials that are widely used in engineering and manufacturing, and they both exhibit unique advantages and limitations in their respective properties and applications.

Density and Weight: Titanium is relatively dense and heavier than aluminum, but is stronger; aluminum's lightweight design is suitable for scenarios that require lightweighting, such as automotive and aerospace.

Hardness and abrasion resistance: Titanium typically has higher hardness and abrasion resistance than aluminum, but aluminum can be surface treated to improve its scratch resistance.

Thermal Conductivity: Aluminum is far superior to titanium in thermal conductivity and is a good heat sink, while titanium has relatively moderate thermal conductivity.

Corrosion resistance: Titanium has excellent corrosion resistance and is suitable for a variety of corrosive environments, while aluminum also has fairly good corrosion resistance.

Aerospace: Titanium is used in the aerospace industry for high-strength, corrosion-resistant components; aluminum is used in lightweight designs such as aircraft structures and aerospace components.

Industrial and Architectural: Titanium is advantageous in high temperature and chemically corrosive environments, while aluminum is used for easy machining, heat dissipation and other needs.

A combination of material selection considerations:

Engineering Needs: When selecting a material, thermal conductivity, corrosion resistance, hardness, weight and other factors need to be taken into account and the choice made based on the specific application scenario.

Cost considerations: Titanium is usually more costly, while aluminum is relatively more affordable, cost is also an important factor in material selection.

Titanium and aluminum each have superior properties and demonstrate their strengths in different applications. Engineers and designers need to weigh these properties, along with other influencing factors, against the needs of a project to select the most appropriate material for a particular application to ensure that the product is optimized in terms of both performance and economics.

Richconn is a precision machine shop with an excellent reputation in the machining and fabrication field, which specializes in providing high-quality CNC machining services for titanium and aluminum. With state-of-the-art machining equipment and an experienced technical team, we offer a diverse range of customized solutions and professional machining services.

Richconn has extensive experience and expertise in the field of material processing and fabrication to provide high-quality customized services to their clients. With a focus on quality, precision and customer satisfaction, we are a trusted choice for a titanium and aluminum machining partner.

Find the Right Corrosion Resistant MetalsOctober 16, 2023Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.view

Find the Right Corrosion Resistant MetalsOctober 16, 2023Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.view Machined Washers: Everything You Need to Know About CNC-Engineered FastenersNovember 8, 2023Welcome to the world of machined washers! If you're reading this, you're about to embark on a journey to discover the fundamental building blocks of precision engineering. Whether you're an engineer, a DIY enthusiast, or a professional seeking the perfect fastener for your project, this comprehensive guide will equip you with the knowledge to make informed decisions and take your projects to the next level.view

Machined Washers: Everything You Need to Know About CNC-Engineered FastenersNovember 8, 2023Welcome to the world of machined washers! If you're reading this, you're about to embark on a journey to discover the fundamental building blocks of precision engineering. Whether you're an engineer, a DIY enthusiast, or a professional seeking the perfect fastener for your project, this comprehensive guide will equip you with the knowledge to make informed decisions and take your projects to the next level.view How to Define Insert? Understanding Its Process and Considerations (Explained)October 19, 2023Everyday objects that we use often involve different materials. For instance, scissors usually have plastic handles and metal blades. Although it may seem straightforward, engineers must carefully con...view

How to Define Insert? Understanding Its Process and Considerations (Explained)October 19, 2023Everyday objects that we use often involve different materials. For instance, scissors usually have plastic handles and metal blades. Although it may seem straightforward, engineers must carefully con...view GD&T Overview: What are the GD&T Symbols?August 23, 2023GDT symbols are the language used in engineering drawings to communicate design specifications and requirements for manufactured parts. GD&T symbol helps designers and manufacturers precisely defi...view

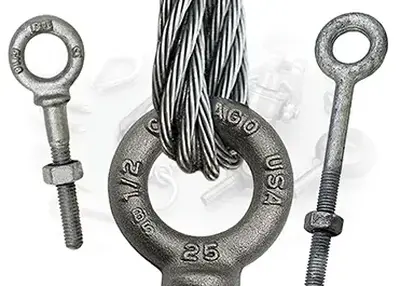

GD&T Overview: What are the GD&T Symbols?August 23, 2023GDT symbols are the language used in engineering drawings to communicate design specifications and requirements for manufactured parts. GD&T symbol helps designers and manufacturers precisely defi...view Machined Eye Bolts: Your Ultimate Guide to Quality and SafetyNovember 9, 2023When it comes to precision engineering and safety, there's no room for compromise. Whether you are involved in industrial operations, construction, aerospace, or recreational equipment, the quality of your components is paramount. Enter Machined Eye Bolts, the unsung heroes that bear the weight of your projects, ensuring safety and performance.view

Machined Eye Bolts: Your Ultimate Guide to Quality and SafetyNovember 9, 2023When it comes to precision engineering and safety, there's no room for compromise. Whether you are involved in industrial operations, construction, aerospace, or recreational equipment, the quality of your components is paramount. Enter Machined Eye Bolts, the unsung heroes that bear the weight of your projects, ensuring safety and performance.view Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view

Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view