China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing. Here are the methods and steps summarized in this article for the majority of consumers to find an excellent precision machining manufacturers in China:

China has many different types of precision machining manufacturers, such as lathe processing, sheet metal processing, casting processing and so on. Therefore, first you need to define the type of products you need to process, so that you can be more targeted in the later election.

Nowadays, the Internet has become the main channel for people to obtain information. We can through the search engine or industry platform, enter the keyword "China precision machining manufacturers", you can get a lot of related websites, forums, social media and other information. In addition, consulting with friends, colleagues and other related professionals can also help find more professional and reliable precision machining manufacturers in Ningbo.

Through internet search and consultation, we can initially identify some precision machining manufacturers in Ningbo. However, in order to get more accurate information, it is better to visit these manufacturers in person. During the inspection, you need to see whether there are complete facilities, advanced processing equipment and skilled operators, which are the signs of an excellent China precision machining manufacturer.

In addition to the equipment and operators mentioned above, an excellent China precision machining manufacturer should also have the advantages of high quality products, fast production cycle and perfect after-sales service. When communicating with the manufacturer, you need to ask about their quality assurance measures and after-sales service after initiating a general contract.

Finally, while confirming the strength and services of a China precision machining manufacturer, consumers also need to pay attention to whether the factory's offer is reasonable. There may be differences in price between different factories, but consumers need to understand what the reasons for the differences are, such as processing technology, materials, quality and other factors will make a difference in the price.

These are the detailed methods and steps on how to find an excellent China precision machining manufacturer. In the selection process, it is necessary to pay attention to the actual processing situation, and comprehensively consider a variety of factors in order to ultimately choose a reliable quality, good service, reasonable price offer China precision machining manufacturers, so as to ensure the best product quality and user experience.

Unlocking the World of Machined Bushes: Your Comprehensive GuideNovember 8, 2023Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.view

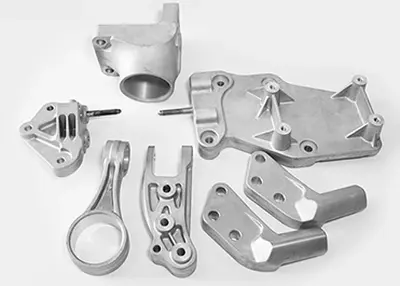

Unlocking the World of Machined Bushes: Your Comprehensive GuideNovember 8, 2023Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.view What Are the Advantages of Cast Aluminum PartsOctober 19, 2023The continuous development of society, people's lives are increasingly high demand for aluminum casting process is also increasing in demand. In our use and use of aluminum casting process, do we understand the aluminum casting production out of aluminum die casting parts have what advantages?view

What Are the Advantages of Cast Aluminum PartsOctober 19, 2023The continuous development of society, people's lives are increasingly high demand for aluminum casting process is also increasing in demand. In our use and use of aluminum casting process, do we understand the aluminum casting production out of aluminum die casting parts have what advantages?view Electroforming vs Electroplating: How They Work and What They DoDecember 6, 2023Electroforming and electroplating are two common metal forming processes that use electricity to deposit metal onto a surface. Both processes involve passing an electric current through a solution called an electrolyte, which contains metal ions.view

Electroforming vs Electroplating: How They Work and What They DoDecember 6, 2023Electroforming and electroplating are two common metal forming processes that use electricity to deposit metal onto a surface. Both processes involve passing an electric current through a solution called an electrolyte, which contains metal ions.view The Complete Guide to Aerospace Fasteners 2023August 24, 2023The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of ai...view

The Complete Guide to Aerospace Fasteners 2023August 24, 2023The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of ai...view Titanium vs. Aluminum: Which is the Best Lightweight Metal?November 23, 2023Titanium and Aluminum are two excellent lightweight metals, and when it comes to machining, the choice of material is a crucial decision. Titanium and Aluminum are both common lightweight metal materials, and both have their own unique advantages in different situations.view

Titanium vs. Aluminum: Which is the Best Lightweight Metal?November 23, 2023Titanium and Aluminum are two excellent lightweight metals, and when it comes to machining, the choice of material is a crucial decision. Titanium and Aluminum are both common lightweight metal materials, and both have their own unique advantages in different situations.view CNC Plastics Selection Guide | Machining MaterialsJune 18, 2024Delve into the realm of engineering plastics to discover a wide range of materials, their unique characteristics, and diverse processing techniques.view

CNC Plastics Selection Guide | Machining MaterialsJune 18, 2024Delve into the realm of engineering plastics to discover a wide range of materials, their unique characteristics, and diverse processing techniques.view

EN

EN

ru

ru