Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.

High-speed steel, as an advanced alloy steel, its main components include carbon (C), molybdenum (Mo), cobalt (Co), tungsten (W), chromium (Cr) and so on. Known for its excellent wear resistance, high-temperature strength and corrosion resistance, HSS is widely used in the fields of tool making, forging molds, cold punching dies, and automotive parts manufacturing.

Its specific properties are as follows:

Wear resistance and hardness: HSS has excellent hardness and wear resistance, making it excellent in high load, high speed working environment such as cutting, stamping and cold extrusion.

High Temperature Strength: HSS maintains high hardness and strength at elevated temperatures, making it suitable for high temperature cutting and heat treating applications.

Corrosion resistance: The alloy composition of HSS gives it excellent corrosion resistance, making it suitable for work in a number of corrosive environments.

Cutting performance: Due to its hardness and wear resistance, HSS is widely used in the manufacture of cutting tools and cutting instruments.

Tungsten steel, also known as tungsten alloy steel, mainly uses tungsten as the alloying element, and cobalt and nickel are also common. Known for its high density, high melting point and excellent high temperature resistance, tungsten steel is widely used in aerospace, medical devices, nuclear energy equipment, electronics industry and other high-tech fields.

The following are the main characteristics of tungsten steel:

High melting point: tungsten steel has a very high melting point, making it less likely to soften in high temperature environments, making it suitable for high temperature tools and parts.

High Density: Tungsten steel has a high density, giving it an advantage in some applications where high weight or quality is required.

High temperature resistance: Tungsten steel maintains stable mechanical properties at high temperatures, making it suitable for aerospace and nuclear energy applications.

Differences in material composition result in HSS and tungsten steel having different properties, and these material properties affect their application areas differently. The following is a detailed description of the differences between these two materials.

High-speed steel mainly contains carbon, molybdenum, cobalt and other elements, while tungsten steel takes tungsten as the main alloying element, and there is a significant difference in the composition of the two.

High-speed steel mainly emphasizes wear resistance, high-temperature strength and corrosion resistance, and is suitable for tool manufacturing and other fields; while tungsten steel is characterized by high density, high melting point and high-temperature resistance, and is suitable for high-tech fields.

High-speed steel is widely used in general machinery manufacturing fields, such as automobile parts, cutting tools, etc.; while tungsten steel is mainly used in high-tech industries, such as aerospace, nuclear energy, electronics industry.

The above is an introduction to the material properties of HSS and tungsten steel and their differences. When making a material choice, it is important to consider the specific needs and application environment to ensure that the selected material can maximize its advantages and meet engineering needs. Whether you're looking for high-temperature cutting tools or high-density parts, a thorough understanding of the characteristics of these two materials can help provide a more informed direction for engineering and manufacturing decisions.

The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view

The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view 18-8 Stainless Steel vs 304: What's the Difference and Which One to Choose?December 7, 2023Stainless steel is one of the most widely used materials in the world, thanks to its excellent properties, such as corrosion resistance, strength, durability, and aesthetics. However, not all stainless steel grades are the same.view

18-8 Stainless Steel vs 304: What's the Difference and Which One to Choose?December 7, 2023Stainless steel is one of the most widely used materials in the world, thanks to its excellent properties, such as corrosion resistance, strength, durability, and aesthetics. However, not all stainless steel grades are the same.view What Is Anodizing: Exploring the Anodizing Process and TypesAugust 31, 2023Anodizing goes beyond surface enhancement; it represents an extraordinary electrochemical transformation that endows a diverse range of metals with exceptional characteristics. If you've ever wond...view

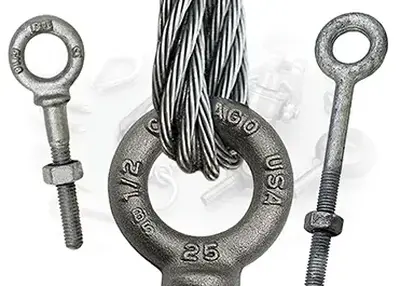

What Is Anodizing: Exploring the Anodizing Process and TypesAugust 31, 2023Anodizing goes beyond surface enhancement; it represents an extraordinary electrochemical transformation that endows a diverse range of metals with exceptional characteristics. If you've ever wond...view Machined Eye Bolts: Your Ultimate Guide to Quality and SafetyNovember 9, 2023When it comes to precision engineering and safety, there's no room for compromise. Whether you are involved in industrial operations, construction, aerospace, or recreational equipment, the quality of your components is paramount. Enter Machined Eye Bolts, the unsung heroes that bear the weight of your projects, ensuring safety and performance.view

Machined Eye Bolts: Your Ultimate Guide to Quality and SafetyNovember 9, 2023When it comes to precision engineering and safety, there's no room for compromise. Whether you are involved in industrial operations, construction, aerospace, or recreational equipment, the quality of your components is paramount. Enter Machined Eye Bolts, the unsung heroes that bear the weight of your projects, ensuring safety and performance.view Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view

Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view Aero-engine Why the Whole Leaf DiskOctober 23, 2023Aero-engine is the heart of the aircraft, also known as the pearl in the crown of industry, the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields.view

Aero-engine Why the Whole Leaf DiskOctober 23, 2023Aero-engine is the heart of the aircraft, also known as the pearl in the crown of industry, the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields.view

EN

EN

ru

ru