When the mechanical parts in the design of the predetermined period and under the specified conditions, can not complete the normal function, it is called failure. General mechanical parts failure form is based on the failure of the external morphological characteristics to the classification, including: wear failure, fracture failure, corrosion failure and distortion failure.

Wear failure is due to the relative friction between the parts of the wear, resulting in the failure of the parts geometry and shape change. Can be divided into adhesive wear, abrasive wear and fatigue wear.

Occurs in two relative sliding surfaces, friction under the action of friction surface plastic deformation, so that the two surfaces welded, shear occurs in the lower strength of the friction surface, resulting in higher strength of the surface of the material adhering to the wear parts of the metal, the formation of adhesive wear, a common form of gluing, the first type of gluing: adhesive weld, the second type of gluing: thermal adhesion.

Due to hard objects or hard particles of cutting or scraping action caused by wear, including two-body wear and three-body wear, typically characterized by "furrow" wear morphology, the main factors such as abrasive hardness, size, size and mechanical properties of the material.

Also known as surface fatigue wear and contact fatigue wear, refers to the relative motion of the two contact body, the formation of cyclic stress in the contact zone exceeds the fatigue strength of the material, resulting in the surface layer of the material spalling down the wear process, the common form of: pitting, flaking, peeling, abrasion.

Fracture is a metal component in the stress of the material separation into two or more parts of the phenomenon is not connected to each other, it is one of the common forms of failure of metal components. Fracture is a serious form of failure, it not only makes the parts failure, and sometimes lead to serious life and equipment accidents. Fracture can be divided into toughness fracture, low temperature brittle fracture and fatigue fracture and creep fracture and other forms.

Fracture before the parts have obvious plastic deformation, fracture is fiber-like. Low-temperature brittle fracture failure: parts below the tough and brittle transition temperature of the material below the work, toughness and plasticity greatly reduced and brittle fracture and failure.

Parts subjected to alternating loads, a certain period of time after the fracture will still occur, fatigue fracture for brittle fracture.

Parts working at high temperatures, when the creep deformation exceeds a certain range, cracks occur within the part and lead to rapid fracture.

Under load conditions, due to environmental factors (e.g., corrosive media), there is often a delayed fracture under low stress to make the part fail.

Corrosion failure is due to the corrosive environment caused by parts and corrosive media chemical or electrochemical reaction, resulting in material surface or internal properties and morphological changes, so that the parts can not realize the expected function. Forms of corrosion include: chemical corrosion, electrochemical corrosion.

Metal parts surface materials and the surrounding dry gas or non-electrolyte liquid in the harmful components of the direct chemical reaction, the formation of corrosion layer, this corrosion is called chemical corrosion.

Electrochemical corrosion is a complex physical and chemical corrosion process. Electrochemical corrosion of metals requires several basic conditions, the presence of electrolyte solution; corrosion area has a potential difference; corrosion area charge can flow freely.

Aberration is an abnormal deformation. Deformation failure of the parts, can not withstand the specified load, can not play a prescribed role, but also with other parts of the operation of the interference.

Elastic distortion failure is a failure within the elastic range, which is related to the stiffness of the part, i.e., the ability of the material to resist elastic deformation when subjected to force, that is to say, whether it can be restored to its original shape and size when the external force is removed.

Shaft parts elastic deformation failure, the shaft parts will make the work of malfunction and support overload; for box parts, it will cause the system vibration. If the failure of the intrinsic frequency and the load frequency into an integer multiple of the relationship, it will cause resonance, is the equipment simply can not work.

When the parts in the macro-obvious plastic deformation, and exceeds the allowable value, that is, plastic deformation failure.

Complex shape of the part size and direction are not uniform deformation, the appearance of warped shape, so that the loss of form and positional accuracy, this situation is known as warpage distortion failure.

In mechanical engineering, the failure of mechanical parts is a complex and critical issue. Failure may occur in many forms, each form has its own unique characteristics and impact. Proper knowledge and understanding of the types of mechanical part failures is critical to preventing and solving problems.

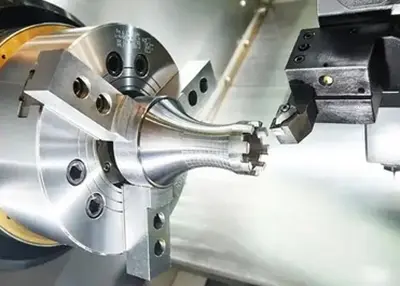

Richconn, your China precision machine shop! We specialize in CNC turning services, CNC milling services, and sheet metal prototyping, providing you with unparalleled precision craftsmanship and high quality machining to get your projects completed with excellence. Partner with Richconn to realize the perfect combination of precision and excellence!

An Introduction to Metal Fabrication: Benefits, Methods & ApplicationsDecember 7, 2023This article introduces sheet metal fabrication in detail. As a versatile metal production technique, it shows extensive applications across numerous industries.view

An Introduction to Metal Fabrication: Benefits, Methods & ApplicationsDecember 7, 2023This article introduces sheet metal fabrication in detail. As a versatile metal production technique, it shows extensive applications across numerous industries.view How Do I Get the Part to Meet the Machining Conditions?October 30, 2023Featuring intricate geometries, often complex CNC parts may require the machining of a series of contours, holes, and recesses to achieve the desired shape and size. Read on to learn more about the complexity of CNC machined part geometries and some of our best tips for reducing design complexity.view

How Do I Get the Part to Meet the Machining Conditions?October 30, 2023Featuring intricate geometries, often complex CNC parts may require the machining of a series of contours, holes, and recesses to achieve the desired shape and size. Read on to learn more about the complexity of CNC machined part geometries and some of our best tips for reducing design complexity.view A Comprehensive Guide to Choosing CNC Machining ToolsJuly 19, 2023Description:Discover how to select suitable CNC machining tools through this comprehensive guide. Explore key considerations for choosing CNC machining tools, different tool types, and expert advice t...view

A Comprehensive Guide to Choosing CNC Machining ToolsJuly 19, 2023Description:Discover how to select suitable CNC machining tools through this comprehensive guide. Explore key considerations for choosing CNC machining tools, different tool types, and expert advice t...view Metal Plating Finishes: Picking the Best for Your Custom PartsMay 16, 2024What are metal plating finishes? How are they applied? What are their benefits and drawbacks? Find out in this guide to metal plating finishes.view

Metal Plating Finishes: Picking the Best for Your Custom PartsMay 16, 2024What are metal plating finishes? How are they applied? What are their benefits and drawbacks? Find out in this guide to metal plating finishes.view How to Use a 5-Axis Machining Center for Titanium Alloy Custom Parts?July 27, 2023As an engineer of five-axis machining centers, I will share with you the method of machining titanium alloy special-shaped parts using a five-axis machining center and the key points of titanium alloy...view

How to Use a 5-Axis Machining Center for Titanium Alloy Custom Parts?July 27, 2023As an engineer of five-axis machining centers, I will share with you the method of machining titanium alloy special-shaped parts using a five-axis machining center and the key points of titanium alloy...view Electrophoretic Coating Process Details and Electrophoretic Paint Selection GuideJune 17, 2024Electrophoretic Coating is a cutting-edge technology that has revolutionized the manufacturing landscape. By offering consistent, uniform surface coverage along with unmatched durability and corrosion...view

Electrophoretic Coating Process Details and Electrophoretic Paint Selection GuideJune 17, 2024Electrophoretic Coating is a cutting-edge technology that has revolutionized the manufacturing landscape. By offering consistent, uniform surface coverage along with unmatched durability and corrosion...view

EN

EN

ru

ru