In the world of precision engineering, the term "machined boss" may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.

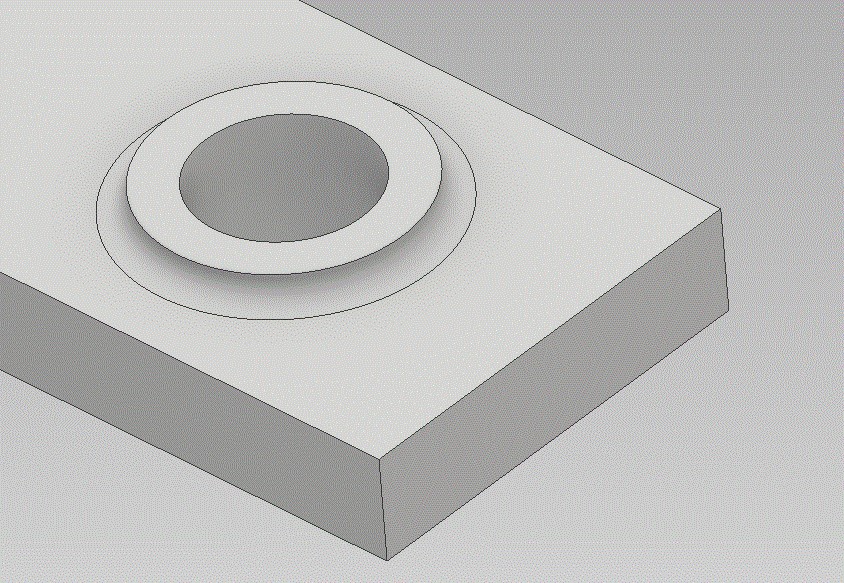

A machined boss, in simple terms, is a raised or thickened area on a workpiece, typically created through machining processes like milling, turning, or drilling. These bosses play a pivotal role in various engineering and manufacturing applications. They can be found as integral components of complex machinery, and their presence is often a testament to precision engineering.

The primary purpose of a machined boss is to provide a stable and designated location for various components, such as threaded fasteners, mounting points, or even fluid passages. Let's dive deeper into its functions.

Machined bosses are like the foundation blocks in the world of mechanical design and engineering. They serve several key functions:

Threaded Connections: One of the most common uses of machined bosses is to provide secure attachment points for threaded fasteners like bolts, screws, or nuts. These bosses ensure that mechanical components stay firmly in place.

Mounting Points: Machined bosses act as reliable mounting points for other components. Whether it's brackets, sensors, or electrical connectors, these bosses offer stability and precision.

Reinforcement: They enhance the structural integrity of a part, making it more robust and capable of withstanding mechanical stress.

Fluid Passages: In some applications, machined bosses incorporate fluid or air passages, allowing for the integration of hydraulic or pneumatic components.

As we continue to explore the world of machined bosses, we'll delve deeper into the manufacturing process and the types of machined bosses in the next section.

[Table: Common Machined Boss Types]

| Boss Type | Description |

|---|---|

| Threaded Boss | Designed for threaded fasteners, ensuring a secure connection. |

| Blind Boss | Used when an attachment point should not extend through the workpiece. |

| Through Boss | Extends completely through the workpiece, offering multiple attachment points. |

| Flush Boss | Sits nearly level with the surface, providing a seamless appearance. |

CNC (Computer Numerical Control) machining is at the forefront of machining technology. It's no surprise that CNC machining is frequently utilized in the production of machined bosses. The precision and versatility of CNC machines make them ideal for creating these critical components.

CNC machines use computer-aided design (CAD) models to create machined bosses with exceptional accuracy. The process begins with the input of a CAD model into the CNC machine's software. The machine then follows these precise instructions to remove material from a workpiece, shaping it into the desired machined boss.

This level of precision allows for the creation of intricate, customized machined bosses that meet the unique specifications of various applications. CNC machining is particularly advantageous for creating threaded bosses, where precise threading is essential for secure fastener attachment.

At Richconn, we take pride in our CNC machining capabilities, which include state-of-the-art milling services. Our CNC milling services utilize advanced machinery and skilled machinists to create machined bosses that meet the highest standards of quality and precision. Whether you require complex shapes or intricate designs, our milling services can accommodate various boss types.

The process of manufacturing a machined boss involves several meticulous steps, each playing a crucial role in ensuring the final product's quality and functionality.

The design phase sets the foundation for creating a machined boss. During this stage, engineers specify the boss's dimensions, features, and placement within the overall design of the part or assembly.

The design of a machined boss considers factors such as the type of fastener it will accommodate, the material of the workpiece, and the expected mechanical loads. These considerations are essential for creating a boss that can withstand the stresses it will encounter in its intended application.

Selecting the right material is a pivotal decision in the manufacturing process. The material chosen for the machined boss can significantly impact its performance and durability. Common materials for machined bosses include:

Steel: Known for its strength and durability, steel is a popular choice for machined bosses in heavy machinery and automotive applications.

Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is a consideration.

Plastics: Some applications benefit from machined bosses made of high-strength plastics, which offer a balance between durability and weight.

The choice of material depends on the specific application, and it's critical to consider factors such as mechanical stress, environmental conditions, and cost-effectiveness.

Richconn, as a trusted CNC machining service provider, offers a wide range of material options to meet your specific machined boss requirements. Our team of experts can guide you in selecting the ideal material for your application.

The actual machining process involves removing material from the workpiece to shape the machined boss. Machining processes may include:

**Milling: A rotating cutting tool removes material to create the boss's shape. It's a versatile process suitable for various boss types. Richconn's state-of-the-art CNC milling services ensure precision and quality in every machined boss we produce.

**Turning: This process is used to create cylindrical bosses with a high degree of precision. It's commonly employed for threaded bosses. Richconn's CNC turning services are known for their ability to craft intricate cylindrical bosses to meet your exact specifications.

The choice of machining process depends on the boss's design and requirements, as well as the capabilities of the machining equipment.

Rigorous quality control measures are essential to ensure that the machined boss meets exact specifications. This step typically involves inspections, measurements, and testing to verify the boss's dimensions, surface finish, and functionality.

Quality control is particularly crucial for threaded bosses, as precise threading is vital for proper fastener engagement. Any deviations from the specified tolerances can result in problems during assembly or operation.

By adhering to these steps in the manufacturing process, engineers and machinists ensure that machined bosses meet the highest quality standards and perform as intended. The resulting components are integral to the functionality and reliability of various mechanical systems and equipment.

Machined bosses come in various types, each tailored to specific applications:

Threaded bosses are designed to accommodate threaded fasteners, providing a secure connection. These bosses play a vital role in various applications where components need to be fastened securely. Richconn offers expert threading services, ensuring that threaded bosses meet the highest standards of precision and reliability.

Blind bosses are used when an attachment point should not extend through the workpiece. They are particularly useful in cases where a clean and unobstructed surface is required. Richconn's precision machining capabilities allow us to create blind bosses with exceptional accuracy.

Through bosses extend completely through the workpiece, offering multiple attachment points. They are versatile and find applications in various industries. Richconn's CNC machining services are capable of crafting through bosses that meet your exact specifications and quality requirements.

Flush bosses sit nearly level with the surface, providing a seamless appearance. These bosses are often used in applications where aesthetics and smooth surfaces are essential. Richconn's expertise in precision machining ensures that flush bosses meet not only functional but also cosmetic standards.

The choice of boss type depends on the specific requirements of your project. Whether you need threaded, blind, through, or flush bosses, Richconn's machining services can provide you with precisely tailored solutions.

The choice of material for a machined boss is a critical decision that significantly impacts its performance, durability, and suitability for specific applications. Each material has unique characteristics that make it suitable for particular use cases. Here are some common materials used for machined bosses:

Steel is renowned for its strength and durability. It is often the material of choice for machined bosses in applications where robustness and load-bearing capacity are paramount. Steel machined bosses are commonly found in heavy machinery, construction equipment, and automotive components. Richconn offers steel machining services that ensure precision and quality for demanding applications.

Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for applications where weight reduction is a consideration. Aluminum machined bosses are frequently employed in aerospace components, consumer electronics, and automotive parts. Richconn's expertise in aluminum machining ensures that these bosses meet both structural and weight-saving requirements.

High-strength plastics have gained popularity in various applications due to their balance between durability and weight. They find use in consumer products, medical devices, and automotive components. Richconn's precision machining services extend to working with high-strength plastics to create machined bosses that meet specific requirements.

In some cases, specialized materials may be required, such as exotic alloys or composites. These materials are chosen based on their unique properties, including resistance to extreme temperatures, corrosive environments, or specific electrical and thermal properties. Richconn's machining capabilities are adaptable to various specialized materials, ensuring that machined bosses meet exceptional standards.

The choice of material should align with the boss's intended function, mechanical stresses, environmental conditions, and cost considerations. Richconn, as an experienced CNC machining service provider, offers comprehensive material selection guidance to ensure your machined bosses perform optimally for your specific applications.

[Table: Common Materials for Machined Bosses and Their Characteristics]

| Material | Characteristics | Common Applications |

|---|---|---|

| Steel | Strength, Durability, Load-bearing Capacity | Heavy Machinery, Construction, Automotive |

| Aluminum | Lightweight, Corrosion Resistance, Weight Reduction | Aerospace, Electronics, Automotive |

| Plastics | High Strength, Lightweight, Versatility | Consumer Products, Medical Devices |

| Specialized | Tailored Properties for Specific Needs | Aerospace, High-Temperature Environments |

Machined bosses are integral to the functionality and reliability of various mechanical systems and equipment. Let's explore some real-world applications that highlight their importance in different industries:

In the automotive sector, machined bosses are extensively used in the assembly of engines, transmissions, and suspension components. Threaded bosses secure critical engine components, ensuring their stability and reliability. Additionally, bosses play a role in mounting sensors and connectors that are vital for vehicle control and safety systems.

The aerospace industry relies on machined bosses to ensure the structural integrity and safety of critical aircraft components. Threaded bosses are used in securing components in aircraft engines, while blind bosses are employed to maintain the aerodynamic integrity of the aircraft's surfaces. The precision and quality of machined bosses are essential in this high-stakes industry.

Machined bosses are prevalent in the assembly of complex machinery and production lines. Through bosses are often used to provide multiple attachment points for various components, enhancing the flexibility and functionality of the equipment. The reliability of machined bosses is crucial in maintaining the efficiency of manufacturing processes.

In the world of robotics and industrial automation, precision is paramount. Machined bosses are employed to secure components that enable robotic arms to perform intricate tasks. The accurate positioning and stability provided by machined bosses are essential for achieving the desired level of automation.

Machined bosses find their way into numerous consumer products, from handheld electronic devices to kitchen appliances. Flush bosses are often used to ensure a smooth and aesthetically pleasing surface, making them an ideal choice for products where appearance matters. Reliable machining is vital to meeting consumer expectations for quality.

As a rapid prototyping companies, Richconn understands the intricacies of creating precision components like machined bosses. Our expertise in CNC machining allows us to deliver high-quality machined bosses that meet your specific requirements. Here's how we can assist you:

Advanced Technology: Richconn utilizes state-of-the-art CNC machines that are capable of crafting precise and complex machined bosses. Our technology ensures accuracy and consistency in every component we produce.

Material Guidance: We provide expert advice on material selection, helping you choose the most suitable material for your machined boss based on your application's requirements.

Customization: Whether you need threaded, blind, through, or flush bosses, we offer customization to ensure that each machined boss meets your exact specifications.

Quality Assurance: Richconn's rigorous quality control measures guarantee that every machined boss adheres to the highest standards. We conduct inspections, measurements, and testing to ensure dimensional accuracy and functionality.

Efficiency and Reliability: We understand the importance of timely production and the reliability of components. Our CNC machining services are designed to meet deadlines without compromising quality.

These real-world applications underscore the significance of machined bosses across diverse industries. Their presence may go unnoticed by the average consumer, but engineers and manufacturers understand their critical role in ensuring the functionality, reliability, and safety of a wide range of products and systems.

The machined bosses are the unsung heroes of precision engineering, offering stability, reliability, and functionality in countless applications. Whether you're in the automotive, aerospace, manufacturing, robotics, or consumer product industry, a firm understanding of machined bosses is key to engineering success. For businesses and professionals looking for high-quality machined bosses, Richconn's CNC machining services offer expertise and precision you can rely on.

Types of Gears: An Overview of Various Mechanical GearsApril 26, 2024This article is about important information you need to know about gears, including types of gears, applications, production and advantages and disadvantages.view

Types of Gears: An Overview of Various Mechanical GearsApril 26, 2024This article is about important information you need to know about gears, including types of gears, applications, production and advantages and disadvantages.view How to Improve the Accuracy of Precision Machining CNC Machine Tools?October 19, 2023With the rapid development of the manufacturing economy, CNC machine tools as a new generation of machine tools in precision machining manufacturing has been widely used. With the rapid development of precision machining technology and the requirements for the accuracy of machined parts, the accuracy of CNC machine tools has also put forward higher requirements.view

How to Improve the Accuracy of Precision Machining CNC Machine Tools?October 19, 2023With the rapid development of the manufacturing economy, CNC machine tools as a new generation of machine tools in precision machining manufacturing has been widely used. With the rapid development of precision machining technology and the requirements for the accuracy of machined parts, the accuracy of CNC machine tools has also put forward higher requirements.view Features Of CNC MillingJune 21, 2022CNC milling is generally a metal fabrication process; however, plastics can also be machined. CNC milling uses a computer to control the tool. The cutting tool then cuts the material from the workpiec...view

Features Of CNC MillingJune 21, 2022CNC milling is generally a metal fabrication process; however, plastics can also be machined. CNC milling uses a computer to control the tool. The cutting tool then cuts the material from the workpiec...view Unveiling the Power of Galvanized Materials: Your Ultimate GuideSeptember 28, 2023Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization.view

Unveiling the Power of Galvanized Materials: Your Ultimate GuideSeptember 28, 2023Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization.view The Brief Introduction to 5 Axis CNC MachineAugust 22, 2023Over the past few years, CNC machining technology has advanced from basic machine tools to more complex ones. Nowadays one of the most cutting-edge techniques accessible is 5-axis CNC machining. It us...view

The Brief Introduction to 5 Axis CNC MachineAugust 22, 2023Over the past few years, CNC machining technology has advanced from basic machine tools to more complex ones. Nowadays one of the most cutting-edge techniques accessible is 5-axis CNC machining. It us...view What Is a Heat Sink? 7 Tips for Choosing the Right Heat SinkSeptember 5, 2023Because of the increasing need for high-performance electronics, advanced devices with fast microprocessors and high transistor densities are being manufactured. This technical modification in such el...view

What Is a Heat Sink? 7 Tips for Choosing the Right Heat SinkSeptember 5, 2023Because of the increasing need for high-performance electronics, advanced devices with fast microprocessors and high transistor densities are being manufactured. This technical modification in such el...view