Welcome to the realm where precision meets innovation – Richconn's CNC machined bottle openers redefine the art of craftsmanship. As a leading CNC machining service provider, Richconn is committed to delivering not just bottle openers, but a symphony of precision, design excellence, and user satisfaction. Join me on a journey through the intricacies of CNC machining, the unique offerings from Richconn, and the factors that set us apart in the world of bottle openers.

Welcome to the intricate world of CNC machined bottle openers, where precision is not just a goal but an obsession. At the heart of Richconn's craftsmanship lies the mesmerizing dance of CNC machining. Let's dive deeper into the core principles and applications that make this technology the backbone of our exceptional bottle openers.

CNC Machining: A Symphony of Precise Machining, or Computer Numerical Control machining, represents the pinnacle of precision engineering. At Richconn, we embrace this technology as the artisan's brush, crafting bottle openers with meticulous detail. The process involves programming computerized machines to precisely cut, shape, and finish materials, resulting in a level of accuracy that traditional methods simply can't match.

The Precision Advantage The beauty of CNC machining lies in its ability to repeat intricate tasks with astonishing precision. Each bottle opener undergoes a symphony of movements guided by computer-controlled precision, ensuring that every cut, groove, and contour is executed flawlessly. This precision not only enhances the visual appeal of our products but also contributes to their longevity and functionality.

Mastering Precision in Bottle Opener Manufacturing The marriage of CNC machining and bottle opener crafting is a testament to technological excellence. Our CNC machines are programmed to cut through materials like stainless steel or aluminum with surgical precision, creating the intricate shapes and designs that define Richconn's products.

Ensuring Consistency in Production One of the key advantages of CNC machining is its ability to maintain consistent quality across large production runs. Every bottle opener produced bears the same level of precision, eliminating variations that might arise in traditional manufacturing methods. This uniformity is not just a testament to our commitment to excellence but also a guarantee to our customers that each Richconn bottle opener is a masterpiece in its own right.

Table 1: CNC Machined Bottle Opener Specifications

| Feature | Description |

|---|---|

| Material | High-grade stainless steel or aluminum |

| Machining Tolerance | ±0.005 inches |

| Surface Finish | Smooth, polished |

| Customization Options | Engraving, color variations, personalized designs |

Table 1 provides a snapshot of the specifications that define Richconn's CNC machined bottle openers, emphasizing the precision and customization options available to our customers.

Now that we've unraveled the precision behind CNC machining, let's embark on a journey through Richconn's manufacturing sanctum. Our commitment to excellence is not just about the end product but is deeply ingrained in the very fabric of our manufacturing process. Join me as we explore the intricacies of Richconn's manufacturing craftsmanship and the stringent measures in place to ensure unparalleled quality.

Richconn: Where Craftsmanship Meets Innovation Richconn isn't just a manufacturer; it's an embodiment of craftsmanship and innovation. Founded on a vision to redefine the standards of precision, our journey is marked by a relentless pursuit of excellence. As we step into our manufacturing facilities, you step into a realm where tradition meets cutting-edge technology.

State-of-the-Art Facilities Our manufacturing facilities are a testament to our commitment to staying at the forefront of technological advancements. Equipped with state-of-the-art CNC machines, quality control systems, and a team of skilled artisans, Richconn transforms raw materials into functional works of art.

The Art of Material Selection Crafting exceptional bottle openers begins with choosing the right materials. Richconn's commitment to durability and aesthetics is reflected in the careful selection of high-grade stainless steel or aluminum. These materials not only ensure the longevity of our products but also contribute to the sleek and polished finish that defines Richconn craftsmanship.

Table 2: Material Specifications for CNC Machined Bottle Openers

| Material | Properties |

|---|---|

| Stainless Steel | Corrosion-resistant, durable, sleek finish |

| Aluminum | Lightweight, corrosion-resistant, aesthetic appeal |

Table 2 provides an overview of the materials used in Richconn's CNC machined bottle openers, highlighting their key properties.

As we immerse ourselves in the material selection process, it becomes evident that every element is chosen with utmost care, ensuring that each bottle opener leaving our facility is not just a tool but a piece of functional art.

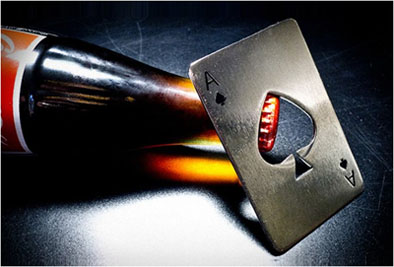

Welcome to the realm of aesthetic exploration, where Richconn's CNC machined bottle openers transcend mere functionality to become expressions of individuality. In this section, we delve into the diverse designs that grace our collection and the personalized touch we offer, ensuring each bottle opener is as unique as its owner.

Elegance Redefined Richconn's CNC machined bottle openers are a testament to the marriage of precision engineering and aesthetic finesse. From sleek minimalist designs to intricate patterns, our collection caters to diverse tastes. Let's explore the distinctive design features that set Richconn's bottle openers apart.

Functional Artistry Each design is not merely ornamental but a carefully crafted balance between form and function. Our artisans leverage the capabilities of CNC machining to create ergonomic designs that enhance the user experience. Whether it's a classic look or a modern twist, Richconn bottle openers marry style with utility.

Crafting Your Unique Story At Richconn, we understand that individuality should extend beyond design preferences. Our personalized customization services allow you to imprint your unique story on your bottle opener. From engraved initials to corporate logos, we offer a spectrum of customization options, ensuring your bottle opener is a reflection of your distinct identity.

Table 3: Customization Options for CNC Machined Bottle Openers

| Customization Feature | Description |

|---|---|

| Engraving | Personalized text or graphics etched on the bottle opener |

| Color Variations | An array of color options to match individual preferences |

| Personalized Designs | Custom patterns or logos for a truly unique touch |

Table 3 outlines the customization options available for Richconn's CNC machined bottle openers, providing a glimpse into the possibilities for personalization.

As we explore the artistic dimensions of our bottle openers, it becomes clear that Richconn doesn't just offer tools; we offer a canvas for self-expression.

Beyond the precision and aesthetics, the true measure of Richconn's CNC machined bottle openers lies in the experience they provide to users. In this section, we'll unravel the engineering marvels that contribute to stellar performance, reliability, and the real-world insights gained from user reviews and feedback.

Engineering Excellence Unleashed The hallmark of a remarkable bottle opener is not just in its design but in how it effortlessly performs its primary function. Richconn's CNC machined bottle openers are engineered to perfection, ensuring a smooth, efficient, and reliable experience with every use.

Precision-Engineered Mechanisms At the heart of our bottle openers are precision-engineered mechanisms. CNC machining allows us to create intricate parts that work seamlessly together, guaranteeing a consistent and reliable bottle opening experience. The precision tolerance of ±0.005 inches ensures that each opener effortlessly glides into action.

Voices of Satisfaction What truly sets Richconn apart is not just our perspective on our products but the firsthand experiences of our users. Through user reviews and feedback, we gain invaluable insights into how our CNC machined bottle openers integrate into daily lives.

Real-World Experiences Users consistently praise the durability, functionality, and aesthetic appeal of Richconn's bottle openers. From home enthusiasts to professional bartenders, our openers have earned a reputation for excellence. This real-world feedback fuels our commitment to continuous improvement and innovation.

Table 4: User Feedback Insights

| Aspect | User Feedback |

|---|---|

| Durability | Praised for robust construction and long lifespan |

| Functionality | Commended for smooth and efficient bottle opening |

| Aesthetic Appeal | Noted for stylish designs that elevate user experience |

Table 4 encapsulates key insights from user feedback, providing a glimpse into the aspects users appreciate in Richconn's CNC machined bottle openers.

As we explore the user-centric facets of our creations, it becomes evident that user satisfaction is not just a goal but the driving force behind our commitment to excellence.

Richconn's commitment to excellence extends beyond the products themselves—it permeates every aspect of our brand. In this section, we'll delve into the foundations of our brand reputation and the comprehensive after-sales services that form the backbone of our commitment to customer satisfaction.

Heritage of Excellence Richconn's journey isn't just a timeline; it's a legacy of precision, innovation, and unwavering commitment. Our brand stands tall, backed by a history of delivering products that redefine industry standards. The trust our customers place in us is a testament to the enduring legacy of Richconn.

Industry Recognition Over the years, Richconn has garnered industry recognition for our dedication to quality. Awards and accolades underscore our position as a leader in CNC machining, further solidifying the trust customers place in the Richconn brand.

Comprehensive Customer Care Our relationship with customers doesn't end with a purchase—it's an ongoing commitment to their satisfaction. Richconn's after-sales service is a testament to our dedication to ensuring that every customer enjoys a seamless ownership experience.

Warranty Coverage and Beyond Richconn provides robust warranty coverage for all our CNC machined bottle openers. In the rare event of an issue, our responsive customer support team is ready to assist, ensuring that our products continue to meet and exceed expectations.

Table 5: After-Sales Service Highlights

| Service Feature | Description |

|---|---|

| Warranty Coverage | Comprehensive coverage for manufacturing defects |

| Responsive Customer Support | A dedicated team ready to assist with inquiries |

| Maintenance Guidelines | Clear guidance on cleaning and upkeep of openers |

Table 5 outlines the key features of Richconn's after-sales service, highlighting our commitment to customer care.

As we explore the pillars of our brand reputation, it becomes clear that trust is not just earned—it's nurtured through a relentless commitment to quality and customer satisfaction.

In a sea of options, Richconn's CNC machined bottle openers emerge as a beacon of precision and quality. In this section, we'll conduct a comprehensive comparative analysis, examining the materials, manufacturing processes, and the delicate balance between price and performance that position Richconn's products at the forefront of the CNC machined bottle opener market.

Materials Matter The choice of materials significantly influences the performance and aesthetics of a bottle opener. Richconn's preference for high-grade stainless steel and aluminum places our products in a league of their own. Let's delve into a comparative analysis of how these materials stack up against alternatives in the market.

Table 6: Materials Comparison

| Aspect | Richconn's Stainless Steel and Aluminum | Alternative Materials |

|---|---|---|

| Durability | Corrosion-resistant, long lifespan | Varies; may not withstand frequent use |

| Aesthetics | Sleek, polished finish | Dependent on material quality |

| Weight | Balanced for easy handling | Varies; may be heavier or lighter |

Table 6 provides a comparative analysis of Richconn's material choices against alternatives, emphasizing the advantages of durability, aesthetics, and balanced weight.

Affordability without Compromise The delicate balance between price and performance is a key consideration for consumers. Richconn excels in offering CNC machined bottle openers that strike this balance. Let's explore how Richconn's products stand out in terms of affordability and performance when compared to alternatives.

Table 7: Price and Performance Comparison

| Aspect | Richconn's CNC Machined Bottle Openers | Alternative Products |

|---|---|---|

| Price | Competitive pricing with premium quality | Varies widely; may compromise quality |

| Performance | Precision engineering for reliable use | Inconsistencies in performance |

| Customization Options | Extensive personalization choices | Limited or no customization options |

Table 7 illustrates the balance between price and performance in Richconn's CNC machined bottle openers compared to alternative products.

As we navigate through the comparative landscape, it becomes evident that Richconn's commitment to high-quality materials, precision engineering, and affordability sets our products apart in the CNC machined bottle opener market.

In this comprehensive exploration of CNC machined bottle openers, we've journeyed through the intricacies of precision engineering, manufacturing craftsmanship, user-centric design, brand reputation, market comparisons, and future innovations. Richconn's commitment to excellence shines through each aspect, ensuring that our bottle openers not only open beverages but open a world of unparalleled quality and innovation. As you explore the possibilities within our collection, remember that each Richconn product is a testament to our dedication to redefining the art of bottle opening. Cheers to a future where every opening moment is a masterpiece!

What is Black Oxide? A Guide on Black Oxide Coating 2023September 5, 2023While there are indeed numerous surface finish types available for manufacturers to choose from, the black oxide coating is a popular choice for many. The black oxide coating offers a combination of v...view

What is Black Oxide? A Guide on Black Oxide Coating 2023September 5, 2023While there are indeed numerous surface finish types available for manufacturers to choose from, the black oxide coating is a popular choice for many. The black oxide coating offers a combination of v...view The Comprehensive Guide: Aerospace CNC Machining Parts and ComponentsJuly 12, 2024CNC machining is widely used in the aerospace industry and aerospace CNC machining parts often require high precision and attention to detail. Let’s dive into cutting-edge technologies crafting vital parts for the aerospace industry in this comprehensive guide.view

The Comprehensive Guide: Aerospace CNC Machining Parts and ComponentsJuly 12, 2024CNC machining is widely used in the aerospace industry and aerospace CNC machining parts often require high precision and attention to detail. Let’s dive into cutting-edge technologies crafting vital parts for the aerospace industry in this comprehensive guide.view![Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]](/uploads/image/20231123/14/chamfer-101-understanding-chamfers-and-chamfered-edge-quick-guide_400x400.webp) Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view

Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view CNC Honing Service A Guide for Concept & SelectionMay 20, 2024CNC honing service helps to achieve tighter tolerances and better surface finishes on a wide range of precision machined parts with a round bore. Here's a simple guide for its concept and selection.view

CNC Honing Service A Guide for Concept & SelectionMay 20, 2024CNC honing service helps to achieve tighter tolerances and better surface finishes on a wide range of precision machined parts with a round bore. Here's a simple guide for its concept and selection.view What Are Tolerances? How Are Tolerances Determined When Designing Machinery?October 26, 2023Tolerance is precise machining and design, the actual parameter values of the parts of the allowable amount of change, such as a certain part of the upper and lower limits were 100, 60, then its tolerance is 40; if the upper and lower limits were +100, -100, then its tolerance is 200.view

What Are Tolerances? How Are Tolerances Determined When Designing Machinery?October 26, 2023Tolerance is precise machining and design, the actual parameter values of the parts of the allowable amount of change, such as a certain part of the upper and lower limits were 100, 60, then its tolerance is 40; if the upper and lower limits were +100, -100, then its tolerance is 200.view The Brief Introduction to 5 Axis CNC MachineAugust 22, 2023Over the past few years, CNC machining technology has advanced from basic machine tools to more complex ones. Nowadays one of the most cutting-edge techniques accessible is 5-axis CNC machining. It us...view

The Brief Introduction to 5 Axis CNC MachineAugust 22, 2023Over the past few years, CNC machining technology has advanced from basic machine tools to more complex ones. Nowadays one of the most cutting-edge techniques accessible is 5-axis CNC machining. It us...view