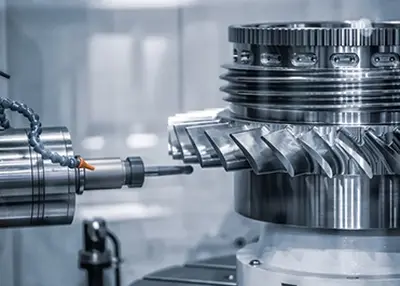

Having the right tool for the task at hand is crucial for completing work efficiently and accurately, especially in a machine shop setting. Given that each machining project is unique, there is no one-size-fits-all toolset for machinists. However, it is advisable to pick essential tools to have readily available and gradually customize your toolbox to cater to specific needs. In this article, we will divide it into several categories and offer some of the most common machinist tools, and suggest ways for you to choose them.

The basic machinery required for metalworking tasks includes tools for cutting, drilling, milling, and turning. Most experts in machining agree that a basic set of tools is necessary to complete the majority of machinist projects. Here is the list of machinest tools catalog.

1. Tools for accuracy measurement

2. Equipment for manual process

3. Power-cutting equipment

The precision of measurements relies on the nature of the data under examination and the specific goals of the analysis, which dictate the suitable techniques for ensuring accuracy. Here is a list of the machinist tooling that are applicable for precise measurement.

Micrometers are the widely used machinist tools essential for novice users, also known as a micrometer screw gauge, widely utilized for precise measurements of object diameters, thicknesses, and lengths. Similar to other machinist measuring tools like calipers and dial indicators, micrometers are available in digital, dial, and vernier variations, each with differing price points. Our suggestion leans towards adopting the digital type for its reduced potential for reading errors.

Calipers are considered crucial measuring instruments for beginners in machining, allowing for accurate measurement of distances between two opposing points on an object. Various types of calipers are available, some of which enable measurements to be read using devices like a ruled scale, a dial, or a digital display. Depending on individual preferences, a choice can be made between a dial or a digital caliper.

A combination square set, commonly referred to as a combination square, is a versatile tool that finds widespread utility in machining applications, particularly for the precise measurement of angles and lengths. Additionally, it can be effectively used to ascertain the center of a shaft's end and verify the squareness of an object.

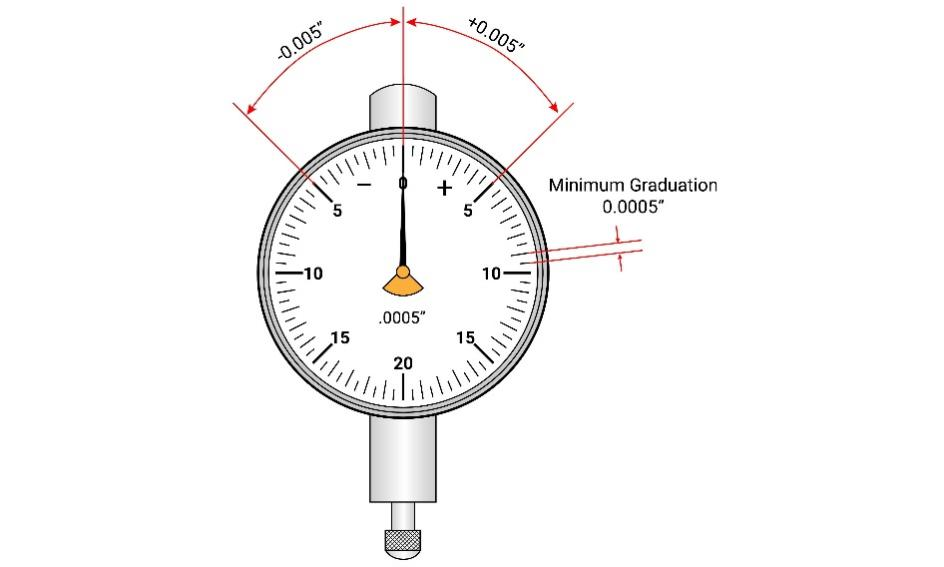

A dial indicator, characterized by a dial display featuring clock hands, serves the purpose of measuring minute linear distances with precision. The versatility of dial indicators is extensive, showcasing significance across various applications such as measuring deck clearances, determining crankshaft thrust, and aligning a vice parallel to the machine axis.

Power-cutting equipment, utilized for cutting various materials like metal, wood, concrete, and others, relies on electricity to provide the necessary energy for cutting. Electric saws, drills, plasma cutters, and laser cutters are instances of cutting tools powered by electricity. Below are examples of a standard list of power-cutting equipment.

Deburring tools are essential for eliminating burrs, which are often concentrated in drilled holes, corners, and narrow slots on a workpiece. Burrs tend to form wherever cutting actions occur. Deburring tools are typically more effective than utilizing files for this purpose.

A grinding wheel is an indispensable tool essential for various operations that require grinding. Consisting of an abrasive compound, a grinding wheel is specifically designed for grinding and performing other abrasive procedures.

Belt sanders are indispensable tools for shaping and finishing materials that require manual precision. Consisting of a rotor that rotates a drum fitted with sandpaper, a belt sander is specifically designed for this purpose. Prior to utilizing a belt sander, it is imperative to understand the potentially aggressive nature of their action on materials. Therefore, it is advisable to use them at the initial stage or selectively as needed.

Manual equipment, defined as machinery operated or controlled manually without reliance on external power sources like electricity, plays a significant role in a wide range of activities. These tools are typically designed to be operated and handled by hand. Examples of manual tools for machinist include various types of hand tools and implements.

In numerous machine shops, hexagonal sockets are frequently encountered for fastening nuts and bolts. However, the process of driving them in can be challenging. By utilizing an Allen wrench set, also known as an Allen key or hex key, individuals have a compact and practical tool at their disposal to facilitate the driving-in process.

The adjustable spanner, alternatively referred to as a Crescent wrench, is a type of spanner featuring an open end and a movable jaw that can be adjusted to fit various sizes. The tool may be known by different names depending on regional variations.

While hammers may not be classified as precision machinist tools, they hold significance as versatile instruments that contribute to achieving accurate outcomes. Hammers play a crucial role in adjusting workpiece components by tapping them into place and are essential for tasks like tapping the center punch and imprinting workpieces with alphanumeric markings.

The center punch, despite being economically priced, serves as an essential tool within a workshop setting and is recommended for inclusion in one's tool arsenal. This tool is particularly valuable for accurately marking positions on workpieces, facilitating the operator in establishing precise locations for drilling and various other machining operations.

Based on the information provided in the previous paragraph, it seems clear that you understand what a machinist does. Are you still uncertain about how to equip yourself with the necessary machinist tools or are machinist tools near me? It can be quite complex to prepare all the machinist tools on your own, and there is a risk of not achieving optimal results due to a lack of expertise. Therefore, it is advisable to opt for outsourcing services from a reliable partner. Richconn is the ideal choice for this purpose.

By selecting our services, your project is entrusted to dependable, skilled, and seasoned professionals. At Richconn, our extensive knowledge of machining processes ensures a seamless experience when engaging our services. Regardless of your timeline, you can easily access our service offerings. You can expect top-notch quality, competitive pricing, and expedited lead times.

Whether you are a workshop owner or a workshop worker, having a clear understanding of the essential tools to invest in can significantly enhance your productivity and efficiency. This article has outlined three key categories of machinist tools crucial for any machining endeavor, aiming to simplify the equipment selection process. By entrusting your machining tasks to Richconn, it will strive to provide you with a superior experience and optimal results.

PVD Surface Treatment: Achieving Durability and AestheticsAugust 14, 2023PVD (Physical Vapor Deposition) surface treatment process is usually used to create hard, durable and beautiful surfaces. It involves applying a thin layer of metal or ceramic coating onto an object t...view

PVD Surface Treatment: Achieving Durability and AestheticsAugust 14, 2023PVD (Physical Vapor Deposition) surface treatment process is usually used to create hard, durable and beautiful surfaces. It involves applying a thin layer of metal or ceramic coating onto an object t...view The Purpose and Importance of Metal Surface FinishApril 4, 2023Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an in...view

The Purpose and Importance of Metal Surface FinishApril 4, 2023Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an in...view Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view

Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view Electrophoretic Coating Process Details and Electrophoretic Paint Selection GuideJune 17, 2024Electrophoretic Coating is a cutting-edge technology that has revolutionized the manufacturing landscape. By offering consistent, uniform surface coverage along with unmatched durability and corrosion...view

Electrophoretic Coating Process Details and Electrophoretic Paint Selection GuideJune 17, 2024Electrophoretic Coating is a cutting-edge technology that has revolutionized the manufacturing landscape. By offering consistent, uniform surface coverage along with unmatched durability and corrosion...view In-depth Understanding of Five-axis CNC Service ProcessingOctober 24, 2022When it comes to cnc machining services, you will definitely think of 5-axis CNC machining. Choosing the right machining solution will lead to a successful production. CNC machining is a procedure use...view

In-depth Understanding of Five-axis CNC Service ProcessingOctober 24, 2022When it comes to cnc machining services, you will definitely think of 5-axis CNC machining. Choosing the right machining solution will lead to a successful production. CNC machining is a procedure use...view Metal Milling Techniques and ApplicationsNovember 3, 2023Are you fascinated by the art of shaping metal into precision components or intricate designs? In this comprehensive guide, I'll walk you through the world of metal milling, from the fundamental concepts to advanced applications.view

Metal Milling Techniques and ApplicationsNovember 3, 2023Are you fascinated by the art of shaping metal into precision components or intricate designs? In this comprehensive guide, I'll walk you through the world of metal milling, from the fundamental concepts to advanced applications.view

EN

EN

ru

ru