At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generally used. In terms of performance, function and adaptability, 4-axis machining is better. Next, RICHCONN will follow you to understand the performance and processing characteristics of the 4 axis CNC machining center.

Although 4 axis CNC machining is now very common in the industry, there is not much theoretical data in the development process, so various problems are often encountered in practical applications, such as tool problems, which will also affect the overall equipment efficiency. Four-axis machining centers are mainly divided into two types: horizontal and vertical. The two types have their own characteristics. Generally, if the application is horizontal, then a B axis can be added to the Y axis. The programming method is similar to the 3 axis; it can rotate 4 sides to achieve the highest precision requirements. Compared with three-axis, four-axis is generally used for the needs of three-axis machine tools that cannot be processed, such as parts that cannot be processed by depth and angle limits, common fan blades, worms and other products.

In fact, many 4-axis machining centers have evolved from the CNC milling operation. The difference between them is whether they have the ability to automatically exchange machining tools. The former can complete automatic exchange very well, with automatic tool change in one clamping, and complete various processing functions. In addition, the four-axis machining center can also complete the linkage control of more than three axes, which can better process equipment with complex surfaces.

Four-axis machining centers generally add a rotary axis, usually called the fourth axis. The corresponding machining center is a four-axis machining center. The so-called machining center actually concentrates the comprehensive functions of CNC drilling, tapping and milling, reducing the work procedures such as tool change and clamping when processing complex products, greatly improving production efficiency.

The four-axis machining center is mainly used to process planes, grooves, and curved surfaces. It is the fastest growing product in CNC machine tools and the most widely used machine tool. The machining center is suitable for machining, mold, shipbuilding industry, automobile and parts, aviation aerospace and other fields. Since the machining center is involved in the fields of national security such as military industry and aerospace, some developed countries regard the development of high-end machining centers as their primary task, and believe that the development of machining centers is directly related to the country's economic construction and national defense security.

To sum up, the four-axis machining center is a high-efficiency and high-precision CNC machine tool. It only needs one clamping to complete the processing of multiple processes. At the same time, it also has a complete tool function and automatic tool change function.

As a professional 4-axis CNC machining supplier in China, Richconn can provide quality 4-axis machining services for you. Feel free to contact us at any time.

How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view

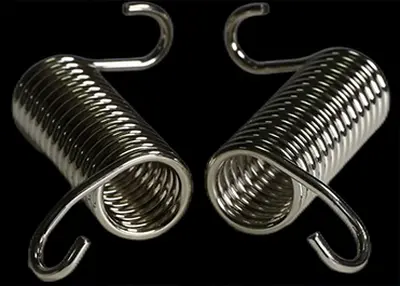

How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view The Tiny World of Springs: A Comprehensive Analysis of Their Types and ApplicationsSeptember 26, 2023Springs are an extremely important and common component in mechanical parts, excelling in enabling motion, shock absorption, providing controllable pushing force, pulling force, and flexible clearance...view

The Tiny World of Springs: A Comprehensive Analysis of Their Types and ApplicationsSeptember 26, 2023Springs are an extremely important and common component in mechanical parts, excelling in enabling motion, shock absorption, providing controllable pushing force, pulling force, and flexible clearance...view Complete List of Machined Hardware Product TypesOctober 19, 2023Hardware: traditional hardware products, also known as "small hardware". Refers to gold, silver, copper, iron, tin five kinds of metal. Artificial processing can be made into knives, swords and other works of art or metal devices. In modern society, hardware is more extensive, such as hardware tools, hardware parts, daily-use hardware, construction hardware and security products. Most of the small hardware products are not final consumer goods.view

Complete List of Machined Hardware Product TypesOctober 19, 2023Hardware: traditional hardware products, also known as "small hardware". Refers to gold, silver, copper, iron, tin five kinds of metal. Artificial processing can be made into knives, swords and other works of art or metal devices. In modern society, hardware is more extensive, such as hardware tools, hardware parts, daily-use hardware, construction hardware and security products. Most of the small hardware products are not final consumer goods.view Everything You Need to Know About CNC Machine ShopSeptember 13, 2023Are you looking to find a CNC machine shop in China? This article covers the information you need to know and helps you choose the best partner.view

Everything You Need to Know About CNC Machine ShopSeptember 13, 2023Are you looking to find a CNC machine shop in China? This article covers the information you need to know and helps you choose the best partner.view What Is the Threading Method for CNC Machining Centers?April 4, 2023Tapping is a common method in CNC machining technologyIt is generally used in the machining of small-diameter threads, but its precision is relatively poor. Therefore, if high precision is required, t...view

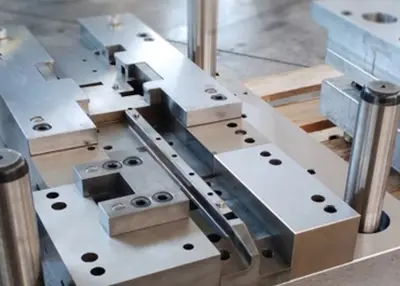

What Is the Threading Method for CNC Machining Centers?April 4, 2023Tapping is a common method in CNC machining technologyIt is generally used in the machining of small-diameter threads, but its precision is relatively poor. Therefore, if high precision is required, t...view Experience Sharing on Design and Manufacturing of Metal Stamping DiesJuly 21, 2023Here, we will share some specific design and manufacturing experiences to provide our understanding of dies accumulated over the years. Through this article, we hope to give you a better understanding...view

Experience Sharing on Design and Manufacturing of Metal Stamping DiesJuly 21, 2023Here, we will share some specific design and manufacturing experiences to provide our understanding of dies accumulated over the years. Through this article, we hope to give you a better understanding...view

EN

EN

ru

ru