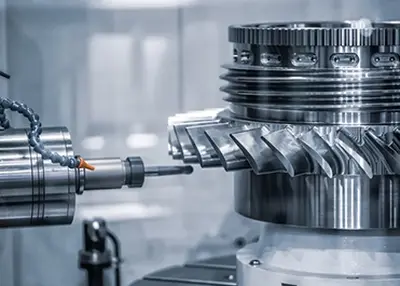

3-axis CNC machining, 4-axis CNC machining, and 5-axis CNC machining are terms that are often heard in our industry work. Some users can't tell. For these types of CNC machining, there are still CNC milling machines that are classified according to the number of axes they operate. These movements determine the characteristics of the parts that can be manufactured and also affect production efficiency and accuracy.

In general, the more degrees of freedom are available, the more complex the geometry can be produced. What's the difference between 3-axis, 4-axis and 5-axis? What are their advantages? Which products are suitable for processing?

3-axis CNC machining generally refers to three axes that move linearly in different directions, such as up and down, front and rear, left and right.

The three-axis can only machine one face at a time, which is suitable for machining some disc parts, which is a limitation for many parts that need to machine holes or grooves on multiple faces.

4-axis CNC machining is to add a rotation axis to the 3-axis, generally 360° rotation on the horizontal plane. But it cannot rotate at high speed, and it is suitable for processing some box parts.

Most 4-axis CNC machines also allow the workpiece to rotate, which is called a b-axis, so that the machine can function as both a milling machine and a lathe.

If you need to drill holes on the side of a part or on the surface of a cylinder, 4-axis CNC machining is the way to go. It greatly speeds up the machining process and has high machining accuracy.

5-axis CNC machining is an additional rotation axis above the 4-axis, generally a 360° rotation of the vertical surface. 5-axis processing can already be fully processed, and one-time clamping can be realized, which can reduce the cost of clamping and reduce product scratches and bumps.

Aerospace CNC Machining: A Comprehensive GuideNovember 6, 2023Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.view

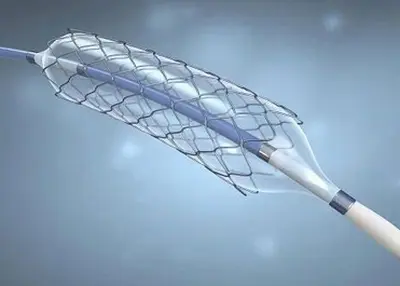

Aerospace CNC Machining: A Comprehensive GuideNovember 6, 2023Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.view Micron-level machining accuracy 2024: Discover the endless possibilities of ultra-high-precision laser cutting processesJanuary 8, 2024Micron-level processing precision is increasingly widely used in various fields, especially in high-end manufacturing industries such as aerospace, electronic products, and medical equipment.view

Micron-level machining accuracy 2024: Discover the endless possibilities of ultra-high-precision laser cutting processesJanuary 8, 2024Micron-level processing precision is increasingly widely used in various fields, especially in high-end manufacturing industries such as aerospace, electronic products, and medical equipment.view Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view

Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view

What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view Galvanized vs. Galvannealed Steel: A ComparisonNovember 28, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. However, steel is also susceptible to corrosion and rust when exposed to moisture and oxygen.view

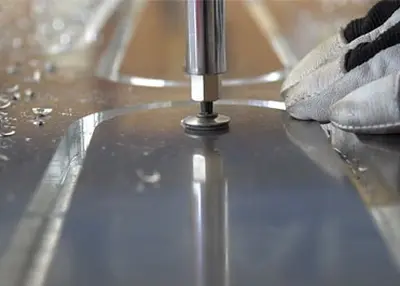

Galvanized vs. Galvannealed Steel: A ComparisonNovember 28, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. However, steel is also susceptible to corrosion and rust when exposed to moisture and oxygen.view CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view

CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view

EN

EN

ru

ru