Are you intrigued by the world of precision manufacturing and curious about the fascinating technology behind it? If so, you've come to the right place. In this comprehensive guide, I'll take you on a journey through the realm of CNC Cutting, revealing its inner workings, diverse applications, and future trends.

CNC Cutting Unveiled: Let's kick off our exploration by delving into the core concept of CNC Cutting. We'll uncover what this technology is and why it's a game-changer in manufacturing.

CNC Cutting, or Computer Numerical Control Cutting, is a highly advanced manufacturing process that combines computer technology with machinery to create precision-cut products. This technology is the driving force behind countless industries, allowing for the production of intricate and accurate components with remarkable efficiency.

The fundamental principles of CNC Cutting involve the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These programs generate detailed instructions that guide the cutting tool's movements with pinpoint accuracy. The result is a flawless cut, whether through metals, plastics, or other materials.

The Ingenious Mechanics: Next, we'll dissect the inner workings of CNC Cutting, uncovering the precise mechanisms that drive this powerful technology.

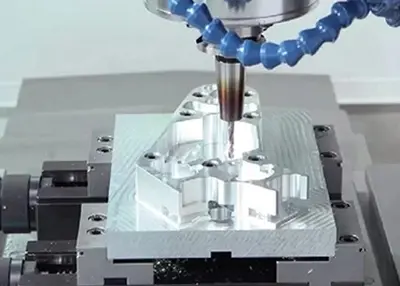

At the heart of CNC Cutting is a cutting tool or bit, which is attached to a machine capable of multi-directional movement. The CNC machine reads the CAD/CAM instructions and translates them into precise movements, controlling the tool's position, depth, and speed. This level of automation ensures consistent, high-quality results, far beyond the capabilities of manual machining.

A Glimpse into History: To truly understand CNC Cutting, we'll take a step back in time and explore its fascinating history and evolution.

The roots of CNC technology can be traced back to the mid-20th century when the need for automated and efficient manufacturing processes became apparent. It wasn't until the 1960s that the first CNC machines were developed, forever changing the landscape of manufacturing. Since then, CNC Cutting has continued to evolve, incorporating advanced features and becoming increasingly accessible to a wide range of industries.

Metals, Marvels, and CNC Cutting: The world of metalworking would be incomplete without CNC Cutting. Discover how this technology revolutionizes the metal industry.

CNC Cutting plays a pivotal role in the metalworking industry. Its precision and versatility make it a go-to choice for crafting intricate metal components. Whether it's shaping automotive parts, aerospace components, or architectural elements, CNC Cutting ensures accuracy and consistency, reducing waste and production time.

Wood and Plastics - Crafted to Perfection: CNC Cutting extends its capabilities beyond metals. Explore its applications in wood and plastic processing.

CNC Cutting isn't limited to metals. It's equally adept at cutting and shaping wood and plastics. This versatility is highly advantageous in industries such as furniture manufacturing, cabinetry, and the creation of intricate plastic molds. The level of detail and precision CNC Cutting offers is unmatched, ensuring top-quality results.

Manufacturing Redefined: In the world of manufacturing, CNC Cutting has emerged as a key player. Learn how it contributes to mass production and customized manufacturing.

CNC Cutting has redefined the manufacturing landscape. In mass production, it streamlines the creation of large quantities of identical parts with utmost accuracy. In customized manufacturing, it enables the creation of one-of-a-kind, tailored components that meet specific requirements. Industries ranging from automotive to medical devices benefit from this flexibility.

Laser Precision: We'll focus on laser cutting technology, its significance, and where it shines.

Laser cutting is one of the most popular CNC Cutting techniques. It uses a highly focused laser beam to make precise cuts. This technology is celebrated for its exceptional speed and the ability to cut intricate patterns with minimal material wastage. From delicate jewelry to heavy-duty metal components, laser cutting finds application in various industries.

Plasma Power: Dive into the world of plasma cutting, understanding when and why it's the preferred choice.

Plasma cutting employs a high-velocity jet of ionized gas to cut through electrically conductive materials. This method excels in cutting through thick metal sheets, making it a common choice in industries like shipbuilding and construction. Its speed and effectiveness make it a valuable addition to CNC Cutting technology.

Water Wonders: Discover the unique features and applications of waterjet cutting.

Waterjet cutting is a fascinating CNC Cutting method that uses a high-pressure stream of water mixed with abrasive particles. This gentle yet precise technique is employed in industries that require intricate cuts, such as aerospace and architecture. Waterjet cutting is known for its ability to cut various materials without heat-affected zones.

Beyond Cutting - Drilling and Milling: Explore how CNC technology is not just limited to cutting but also includes drilling and milling.

CNC technology extends its capabilities beyond cutting. It seamlessly integrates drilling and milling into its repertoire. This versatility allows for the creation of holes, pockets, and intricate designs with pinpoint accuracy. From printed circuit boards to the production of complex 3D shapes, CNC drilling and milling offer endless possibilities.

The Art of Material Selection: Selecting the right material for CNC Cutting is crucial. We'll guide you through the decision-making process.

Choosing the right material is paramount to the success of CNC Cutting projects. The selection depends on factors such as the material's hardness, thermal conductivity, and application. For example, metals like aluminum, steel, and titanium have different cutting requirements due to their distinct properties.

Fine-Tuning Parameters: Uncover the secrets of optimizing cutting speed, power, and cutting head parameters for top-notch results.

To achieve optimal results, CNC operators must fine-tune various parameters. Cutting speed, power, and the cutting head's alignment all play a significant role. Adjusting these parameters based on the material and desired output ensures precision and efficiency.

The Digital Manufacturing Revolution: Gain insights into the core concepts of digital manufacturing and how CNC Cutting fits in perfectly.

Digital manufacturing is revolutionizing the industry by using data-driven technologies to improve efficiency and product quality. CNC Cutting is a cornerstone of digital manufacturing. It seamlessly integrates with digital design and production processes, reducing human error and waste. This synergy between CNC Cutting and digital manufacturing is shaping the future of industry.

Smart CNC Cutting Systems: Explore the exciting future of CNC Cutting, including the integration of artificial intelligence for smarter, more efficient processes.

The future of CNC Cutting is marked by smart systems. Artificial intelligence and machine learning are being applied to optimize cutting parameters, predict maintenance needs, and enhance overall productivity. These advancements lead to reduced downtime and increased precision, making CNC Cutting even more appealing for a wide range of industries.

Advantages of CNC Cutting: We'll discuss the numerous advantages that CNC Cutting brings to the table, from precision to efficiency.

CNC Cutting offers a multitude of advantages. These include pinpoint precision, consistency in output, reduced waste, faster production times, and the ability to handle complex designs. Industries rely on CNC Cutting to meet high-quality standards and stay competitive.

Challenges to Overcome: Even with its strengths, CNC Cutting has limitations. Discover the hurdles and ways to overcome them.

While CNC Cutting is highly versatile, it's not without its challenges. Issues such as high initial costs, complex programming, and the need for skilled operators can pose hurdles. However, these challenges can be addressed through proper training and leveraging the expertise of CNC service providers.

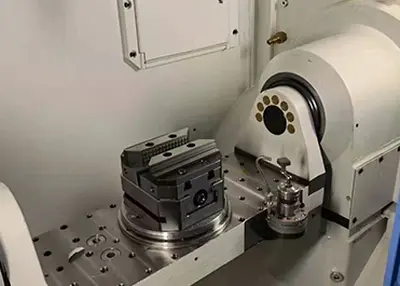

Richconn's Precision Machining Overview: If you're considering precision machining, Richconn's services are a must-see. Learn about the company's expertise and offerings.

Richconn is a prominent player in the world of CNC Cutting and precision machining. As a leading Chinese CNC precision machine shop, Richconn offers a wide range of precision machining services, including CNC Cutting. With years of experience and a dedication to quality, Richconn is the go-to choice for businesses seeking top-notch machining solutions.

As a leading Chinese CNC machining service company, Richconn is at the forefront of CNC Cutting technology. With its state-of-the-art equipment and a team of experts, Richconn offers precision cnc turning service and cnc milling service tailored to your specific needs. Its commitment to excellence is evident in its successful projects and satisfied clients.

If you're ready to unlock the full potential of CNC Cutting for your projects, don't hesitate to contact Richconn for personalized consultation and precision machining solutions. The future of precision manufacturing is here, and Richconn is your trusted partner on this exciting journey.

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view Metal Plating Finishes: Picking the Best for Your Custom PartsMay 16, 2024What are metal plating finishes? How are they applied? What are their benefits and drawbacks? Find out in this guide to metal plating finishes.view

Metal Plating Finishes: Picking the Best for Your Custom PartsMay 16, 2024What are metal plating finishes? How are they applied? What are their benefits and drawbacks? Find out in this guide to metal plating finishes.view CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view

CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view How do you charge for sleeve parts machining?October 31, 2023Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote.view

How do you charge for sleeve parts machining?October 31, 2023Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote.view Smart Savings: How to Optimize Your CNC Projects with Cheap MaterialsDecember 4, 2023In the ever-evolving world of manufacturing, CNC machining has emerged as a game-changer. This revolutionary technology has enabled businesses to enhance productivity, reduce errors, and improve preci...view

Smart Savings: How to Optimize Your CNC Projects with Cheap MaterialsDecember 4, 2023In the ever-evolving world of manufacturing, CNC machining has emerged as a game-changer. This revolutionary technology has enabled businesses to enhance productivity, reduce errors, and improve preci...view Five Axis CNC Machining Features and AdvantagesNovember 4, 2022Five-axis machining machines to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way...view

Five Axis CNC Machining Features and AdvantagesNovember 4, 2022Five-axis machining machines to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way...view

EN

EN

ru

ru