Aluminum is one of the most popular materials for CNC machined parts - here are six reasons why.

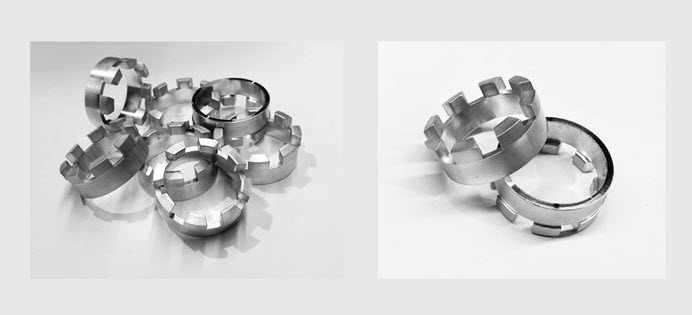

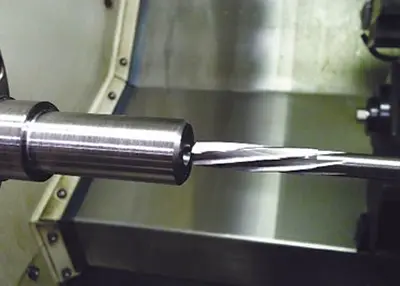

If you ask any CNC precision machine shop about machining aluminum, they will point out its simplicity. Aluminum is very dimensionally stable, so you can cut away a lot of it and still keep the residual stress within limits. Using carbide tools and modern coolants will give you an excellent finish. For a matte finish, you can bead blast the parts or anodizing them for a uniform aesthetic finish and added corrosion resistance.

Most importantly, this machinability helps keep the cost of your part down. However, you choose a material based on the properties you need for your part, so what else does aluminum have to offer?

Aluminum is lighter than most metals. So if you're looking to save weight, it's a great choice. While pure aluminum has a tensile strength of less than 100 Mpa, it can be hardened as follows:

* Alloying, mixing with other elements, improves the grain structure.

* Heat treatment, heating and then cooling within a certain time to produce crystals of ideal size.

* Work hardening, where the metal is intentionally deformed to change its grain structure. This is usually done during heat treatment (e.g., rolling), but can also be done after the fact (during forging).

A "temper" designation indicates the exact condition or strength of the resulting material, H for "hardened" and T for "thermal."

It is worth noting that most aluminum alloys have a higher strength-to-weight ratio or specific strength than 316L stainless steel.

While titanium clearly emerges as the winner from the table below, when stiffness and weight savings are important, the high-strength aluminum alloys are a great cost-effective alternative when budget is a concern.

Since aluminum is a good base material to work with, there are a variety of alloys with different properties and uses to meet your needs.

These are divided into nine different series, with each series numbered as a thousand, so 6000 series for example, which is then further subdivided by a number. Generally, the closer the aluminum grade number is to another, the more similar they are, so 5082 and 5083 are almost identical.

Here are some of the most popular grades:

* 2024 - Aerospace grade with high fatigue strength. Alloying with copper trades off tensile strength (UTS) for more ductility/toughness.

* 5083 - Marine grade, with good corrosion resistance due to higher magnesium content.

* 6082 - Universal use and aerospace grade. A good mix of strength, ductility and corrosion resistance conditions high versatility and widespread use. This is achieved by alloying with a mixture of magnesium and silicon (also roughly equivalent to 6061 grade).

* 7075 - High strength aerospace grade, well balanced properties, especially under high static loads. It can be heat treated and contains more zinc, as well as magnesium and chromium.

Corrosion resistance varies by grade, but aluminum is an excellent choice if that's what you expect from your material. The metal and its alloys have an ideal affinity for oxygen - metals that are too reactive, such as magnesium, oxidize easily, while less reactive metals form a loose oxide film, such as rust on iron and steel.

In contrast, aluminum, when exposed, forms a passivating layer of aluminum oxide that seals the surface and prevents further oxidation and erosion. This layer is "self-healing" even when scratched, so the material does not need to be painted or surface treated. This means a cost savings in manufacturing and life cycle costs. You can enhance this natural corrosion resistance by anodizing - but more on that later.

While copper is often the material of choice when it comes to conductivity, aluminum is often used for electrical components because it is much cheaper and lighter. In fact, it's often used for bus bars, battery cables and connectors, especially in the automotive industry and electric vehicles.

Its good thermal conductivity also means that it is often used for heat sinks and heat dissipation.

With sustainability high on most people's agendas, it's good news that an estimated 75% of all aluminum produced remains in circulation. Recycling aluminum uses much less energy than producing it, and as long as we can keep contaminants under control, it can be used again and again.

It's already been mentioned that you can get a great finish by machining this material, and that aluminum is naturally corrosion resistant. For even better aesthetics, you can even have it anodized in different colors.

This is a surface finishing process that not only increases the wear and corrosion resistance of a material, but also makes it easier to color. At Richconn, we offer both decorative anodizing (Type II) and Type III, in which an even thicker layer of 50µm provides additional protection.

The process increases the thickness of the passivating oxidized layer through the use of acids as well as an electrolytic process.

The choice of material for your part is critical and is based on what properties you want the part to have. Aluminum is often a good choice for the reasons mentioned above, but there are many other metal and plastic options. To help you make the right choice for custom cnc machining, we've created a pocket-sized CNC material selector to serve as a quick reference guide.

If you have any questions about our services at Richconn, please contact an applications engineer at sales@richconn.com.cn or +86-0755-28025755. Have a finished design for custom 3D printing? Upload it now to get a quote.

Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view

Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view How to Reduce the Cost of CNC Machined Parts Through Structural DesignOctober 20, 2023CNC machined parts, i.e. parts processed by CNC equipment, CNC machining, usually refers to the precision machining method digitally controlled by a computer, which has become a common method of machining in nowadays.view

How to Reduce the Cost of CNC Machined Parts Through Structural DesignOctober 20, 2023CNC machined parts, i.e. parts processed by CNC equipment, CNC machining, usually refers to the precision machining method digitally controlled by a computer, which has become a common method of machining in nowadays.view Machining tips and precautions in grooving and cutting offNovember 17, 2023The cutoff and grooving process is an important part of CNC turning machining and presents many unique challenges. During the machining process, the limitations of machine tool and tool rigidity, cooling conditions, programming techniques, tool performance and many other factors can cause problems for machining efficiency, quality and safety.view

Machining tips and precautions in grooving and cutting offNovember 17, 2023The cutoff and grooving process is an important part of CNC turning machining and presents many unique challenges. During the machining process, the limitations of machine tool and tool rigidity, cooling conditions, programming techniques, tool performance and many other factors can cause problems for machining efficiency, quality and safety.view Understanding the Properties of Anodizing Process in One ReadingApril 4, 2023Nowadays, the use of metal technology is quite popular, and many machines in the market have large metal parts. One of the surface treatment processes for metal is anodizing, which is very commonly us...view

Understanding the Properties of Anodizing Process in One ReadingApril 4, 2023Nowadays, the use of metal technology is quite popular, and many machines in the market have large metal parts. One of the surface treatment processes for metal is anodizing, which is very commonly us...view Aero-engine Why the Whole Leaf DiskOctober 23, 2023Aero-engine is the heart of the aircraft, also known as the pearl in the crown of industry, the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields.view

Aero-engine Why the Whole Leaf DiskOctober 23, 2023Aero-engine is the heart of the aircraft, also known as the pearl in the crown of industry, the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields.view Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view

Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view

EN

EN

ru

ru