When comparing the material properties of thermoplastics used in injection molding with "thermoplastic-like" materials used in an industrial 3D printing technology such as stereolithography (SLA), many factors come into play.

SLA is a 3D plastic printing process that uses a thermoset liquid (not a thermoplastic) that is cured layer-by-layer with UV light to produce the final parts. Because of this major difference in manufacturing processes, material properties such as tensile strength, heat deflection temperature, and flexural modulus may differ from those of the traditional SLA counterpart. In addition, SLA produces anisotropic properties where the X, Y, and Z axis values can be different depending on the orientation of the part - a consideration unique to 3D printing processes.

As part of our 3D printing service, we offer a comprehensive selection of thermoplastic SLA materials. What will surprise you, however, is the versatility and range of potential applications for SLA parts. In the following tables and diagrams, we introduce each material and its properties, and compare them to each other (as well as to injection-molded plastics) to help you decide how best to implement SLA.

The versatility and range of applications for 3D-printed SLA parts may surprise you.

Advanced High Temp (Accura 5530), a PC-like material, is best suited for parts that require strength and stiffness combined with high temperature resistance, such as automotive or under-the-hood electrical components. Thermal post-cure can further improve the heat deflection temperature of the part, but at the expense of durability. Note that thermal post-curing will cause the color of the part to take on a slightly amber hue.

Ceramic-like White (Advanced High Temp PerFORM) is widely used for automotive housings, electrical enclosures, wind tunnel testing and other components requiring heat resistance and strength. It combines superior heat tolerance with strength and stiffness. Thermal post-hardening can further improve mechanical properties and heat resistance, but the material then becomes more brittle.

| Test method | PC-like Advanced High Temp (Accura 5530) | PL Lexan 940 (injection molded) | Ceramic-like White (Advanced High Temp PerFORM) | |

|---|---|---|---|---|

| Water absorption | DIN EN 120 62 | 0.55 ± 0.15% (20 ºC, 50 % relative humidity) | 24 Std.: 0,15 % | 0.35 ± 0.15% |

| Young's modulus (x-y plane) | DIN EN ISO 527* | 3,400 ± 400 MPa | -- | 10,000 ± 1,000 MPa |

| Tensile strength (x-y plane) | DIN EN ISO 527* | 50 ± 10 MPa | Yield: 8,990 psi/62.0 MPa | 70 ± 10 MPa |

| Elongation at break (x-y plane) | DIN EN ISO 527* | 3 ± 2% | 90% | 1.5 ± 1% |

Diagram 1: Two PC-like materials and an injection-molded PC thermoplastic are compared in four material property categories.

*Test speed 10 mm/min.

ABS-like Black (Accura Black 7820) has high strength and good dimensional stability, even under high humidity. The material is black in color and is widely used for automotive parts, consumer packaging, electrical enclosures and toys due to its impact resistance and ease of post-processing, which gives the overall impression of production quality.

MicroFine™ is a Richconn exclusive material that can be used to produce extremely intricate micro resolution structures. MicroFine™ is available in green and gray. Layer thicknesses of 0.025 mm and structure sizes of 0.07 mm are possible with MicroFine™ to enable applications that require parts with volumes less than 25x25x25 mm³.

ABS-like translucent/transparent material (Somos Watershed XC 11122) is a strong, durable, ABS-like material with low moisture absorption. It is virtually colorless and mimics a clear engineering plastic. Because of its high transparency, Watershed is a perfect material for prototyping lenses, flow visualization models, and microfluidics. Note that post-processing is required to make the material functionally transparent. Watershed retains a very slight light blue hue afterward.

ABS-like White (Accura Xtreme White 200) provides strength and durability and is well suited for applications requiring flexible snap-fit joints. Note that ABS-like White (Accura Xtreme White 200) has the lowest heat deflection temperature of the SLA materials offered by Richconn.

ABS-like Black (Accura Black 7820) | MicroFine™ | ABS-like translucent/transparent (Watershed XC 11122) | ABS-like White (Accura XTREME White 200) | ABS Bayblend FR 110 (injection molded) | |

|---|---|---|---|---|---|

Water absorption | 0.25 ± 0.15% | 0.85% ± 0.15% (ASTM DS70-98) | 0.35 ± 0.15% | 0.65 ± 0.15% | 0.050% 23 ºC |

| Modulus of elasticity (x-y plane) DIN EN ISO 527* | 3,000 ± 400 MPa | -- | 2,900 ± 400 MPa | 3,300 ± 400 MPa | -- |

| Tensile strength (x-y plane) DIN EN ISO 527* | 55 ± 10 MPa | 60 ± 10 MPa (ASTM D638M) | 55 ± 10 MPa | 55 ± 10 MPa | Yield strength: 60 MPa |

| Elongation at break (x-y plane) DIN EN ISO 527* | 5 ± 3% | 8 ± 4% (ASTM D638M) | 6 ± 3% | 9 ± 5% | >50% |

Chart 2: Four ABS-like materials and an injection-molded ABS thermoplastic are compared in four material property categories.

*Test speed 10 mm/min.

Typically used in healthcare (e.g., for prostheses, earplugs, or wearables) and other industries (e.g., automotive or engineering) for products such as seals, hoses, and gaskets. This material is biocompatible and has passed ISO DIN EN 10993-05 (tests for in vitro cytotoxicity) and ISO DIN EN 10993-10 (tests for irritation and skin sensitization) certifications. The material has high resistance to harsh environmental conditions, various acids, bases and non-polar solvents. The printed parts are water repellent, insulating and have high gas permeability.

| Elastosill R 3003/30 A/B LSR | Elastosill R 3003/50 A/B LSR | Echtes Silikonmaterial A60 | Elastosill 3003/60 A/B Transparent | Elastosill 3003/70 A/B Transparent | ||

| Technology | Injection molding | Injection molding | 3D printing | Injection molding | Injection molding | |

| Color | - | Transparent | Transparent | Transparent | Transparent | Transparent |

| Shore A hardness | - | 30 | 50 | 60 | 60 | 70 |

| Tensile strength | N/mm3 | 7.5 | 9.9 | 8 | 9.5 | 8.6 |

| Elongation at break | % | 620 | 480 | 360 | 340 | 290 |

| Tensile strength | N/mm | 23 | 29 | 17 | 27 | 20 |

| Rebound resilience | % | 61 | 62 | >80 | 67 | 71 |

| Compression set | % | 10 | 13 | <15 | 12 | 12 |

| Density | g/cm3 | 1.09 | 1.13 | 1.15 | 1.13 | 1.13 |

Real silicone compared to LSR Elastosill Shores.

| Property | Test method | Value | |||

| Color | - | Transparent | |||

| Shore A hardness | ISO 7619-1 | 20 | 35 | 50 | 60 |

| Density | ISO 1183-1 A | 1.05 g/cm3 | 1.08 g/cm3 | 1.11 g/cm3 | 1.13g/cm3 |

| Tensile strength (x-y plane) | ISO 37 Type 4 | 4.9 N/mm2 | 5.5 N/mm2 | 7.25 N/mm2 | 8.5 N/mm2 |

| Elongation at break (x-y plane) | >1000% | 650% | 530% | 360% | |

| Tensile strength | ASTM D624 Type C | 5.8 N/mm | 10 N/mm | 11 N/mm | 17 N/mm2 |

| Rebound resilience | ISO 4662 | >80% | >80% | >80% | >80% |

| Compression set | DIN ISO 815-1 Type B | <25% | <20% | <20% | <20% |

The different true silicone shores available from Protolabs and how they compare.

The various true silicone shores available from Richconn and how they compare.

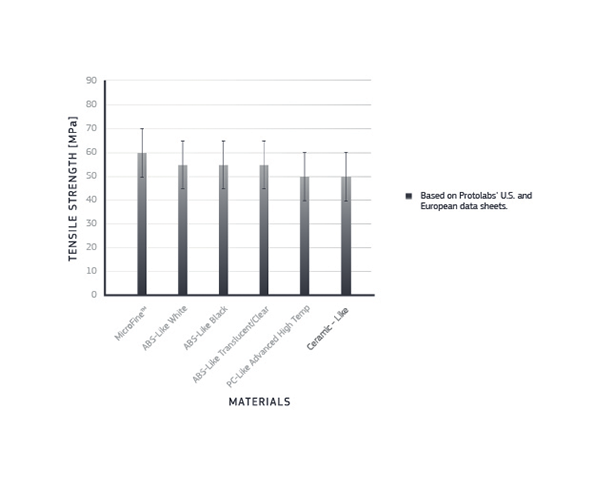

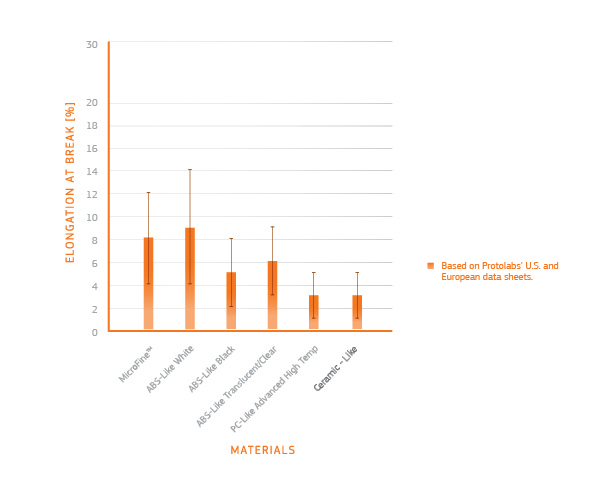

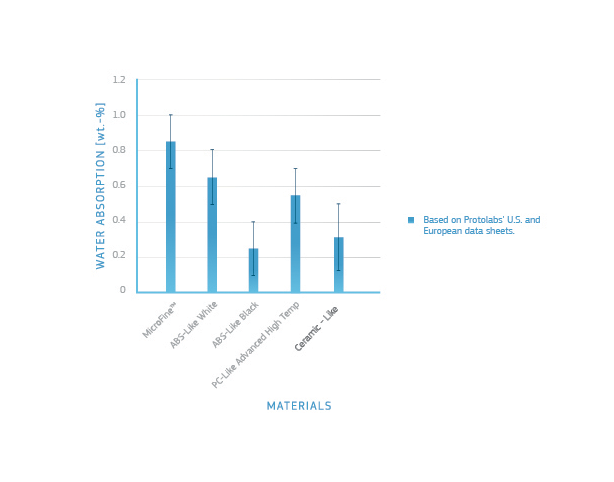

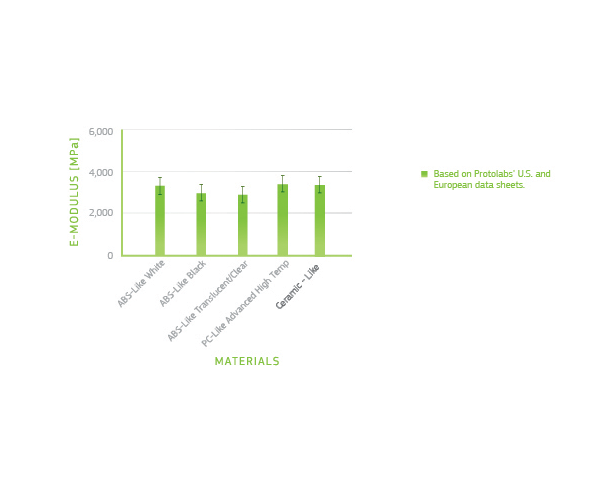

The following charts compare different thermoplastic materials suitable for SLA printing in terms of various material properties: Tensile Strength, Elongation at Break, Water Absorption, and Young's Modulus.

Tensile strength

Elongation at break

Water absorption

Young's modulus

Unlike thermoplastics, UV light and moisture will alter the appearance and mechanical properties of SLA materials if they are not protected by coating or painting. Over time, warpage, yellowing and brittleness of some parts may occur. SLA parts are not intended for long-term use in many cases, but it can be useful to have the short-term benefits of highly detailed mold and fit parts in mind for early prototyping.

You should work closely with 3D printing experts to select the right material for your project and ensure that the build orientation is optimized for your part applications. Check out our guide to 3D printing materials for a comprehensive overview of additive materials, both plastic and metal, for all technologies.

Deepen your knowledge of stereolithography at richconn-cnc.com. If you have any questions about 3D printing or our services, contact an application engineer at sales@richconn.com.cn or +86-0755-28025755.

Already created a design for 3D printing? Upload it now and request an instant quote.

How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view

How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view

ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view Die Casting Machine: A Detailed ReviewMarch 6, 2024Die casting machines are essential in the manufacturing industry. Let's delve into a detailed review of their key features, benefits, and applications.view

Die Casting Machine: A Detailed ReviewMarch 6, 2024Die casting machines are essential in the manufacturing industry. Let's delve into a detailed review of their key features, benefits, and applications.view Experience Sharing on Design and Manufacturing of Metal Stamping DiesJuly 21, 2023Here, we will share some specific design and manufacturing experiences to provide our understanding of dies accumulated over the years. Through this article, we hope to give you a better understanding...view

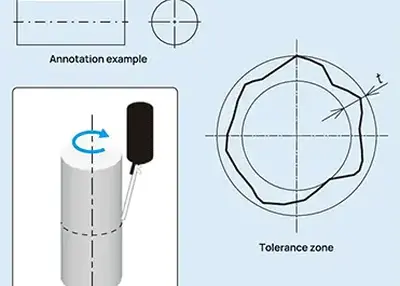

Experience Sharing on Design and Manufacturing of Metal Stamping DiesJuly 21, 2023Here, we will share some specific design and manufacturing experiences to provide our understanding of dies accumulated over the years. Through this article, we hope to give you a better understanding...view Unveiling Precision: Exploring Roundness, GD&T, and Advanced Measurement TechniquesNovember 21, 2023Are you ready to delve into the world of precision engineering? Let's embark on a journey to unravel the intricacies of roundness, its symbiotic relationship with GD&T, and the cutting-edge techniques defining its measurement standards.view

Unveiling Precision: Exploring Roundness, GD&T, and Advanced Measurement TechniquesNovember 21, 2023Are you ready to delve into the world of precision engineering? Let's embark on a journey to unravel the intricacies of roundness, its symbiotic relationship with GD&T, and the cutting-edge techniques defining its measurement standards.view Process Analysis of CNC MachiningAugust 10, 2022CNC machining refers to the processing that the control system issues commands to make the tool perform various movements that meet the requirements, and express the shape and size of the workpiece in...view

Process Analysis of CNC MachiningAugust 10, 2022CNC machining refers to the processing that the control system issues commands to make the tool perform various movements that meet the requirements, and express the shape and size of the workpiece in...view

EN

EN

ru

ru