In today's fast-paced technological landscape, where precision and efficiency are critical, the manufacturing of electronics enclosures demands innovative solutions. At the forefront of this revolution is the cutting-edge technique of CNC cutting aluminum sheets. This blog aims to delve deeper into the intricacies of CNC cutting technology and its transformative impact on the fabrication of electronics enclosures.

CNC cutting, driven by computer numerical control, stands as a pinnacle of precision machining. When applied to aluminum sheets, this technique adds a layer of sophistication to the manufacturing process. The process involves utilizing advanced machinery guided by computer programs to carve out intricate designs and precise dimensions from aluminum sheets. This method offers a level of accuracy that traditional cutting methods struggle to achieve. In the realm of electronics enclosures, where seamless fits and precise measurements are non-negotiable, CNC cutting aluminum sheets emerges as the go-to solution for manufacturers striving for perfection.

The application of CNC cutting technology to aluminum sheets brings forth a myriad of advantages that significantly impact the quality and functionality of electronics enclosures. Aluminum, known for its lightweight yet robust nature, becomes the ideal canvas for CNC cutting. The process allows for the creation of intricate designs, precise openings for ports, and customized shapes that cater to the specific needs of electronic components. The result is not merely an enclosure; it's a meticulously crafted housing that enhances both the functionality and aesthetics of electronic devices. The versatility of CNC cutting also enables manufacturers to experiment with various designs, ensuring that the enclosure meets both technical and design requirements.

Precision Openings: CNC cutting ensures precise openings for ports, connectors, and buttons, ensuring seamless integration with electronic components.

Intricate Designs: Manufacturers can experiment with intricate designs, patterns, and shapes that go beyond the limitations of traditional cutting methods.

Customization: The flexibility of CNC cutting allows for customization based on the unique specifications of electronic devices, meeting both functional and design requirements.

Lightweight Strength: Aluminum, as the material of choice, provides a balance of lightweight construction and structural integrity, ideal for electronics enclosures.

As technology progresses, the future of CNC cutting aluminum sheets holds exciting possibilities for further refining precision and efficiency. Manufacturers are anticipated to push the boundaries of precision by achieving even finer details, faster machining speeds, and increased automation. The integration of artificial intelligence (AI) and machine learning into CNC cutting processes may usher in a new era of self-optimizing machines. These advancements not only promise enhanced precision but also increased efficiency in the manufacturing process, ultimately impacting the cost-effectiveness of producing high-quality electronics enclosures.

In conclusion, the union of CNC cutting technology and aluminum sheets represents a transformative force in the realm of electronics enclosure fabrication. The precision, versatility, and efficiency offered by CNC cutting redefine the standards of customization and quality in the creation of enclosures for electronic devices. As technology continues to advance, the future promises a more refined and automated CNC cutting process, ensuring that electronics manufacturers can consistently deliver enclosures that meet the ever-growing demands of precision and innovation.

How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view

How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view What Are the High Temperature and Corrosion Resistant High Hardness Alloy Wear Resistant Metal Materials?October 30, 2023Corrosion-resistant metals are used in a wide range of applications, from the culinary industry to aerospace applications. Like most metals, they provide structural strength and heat resistance, but the metals listed in this article are also more resistant to corrosion than others.view

What Are the High Temperature and Corrosion Resistant High Hardness Alloy Wear Resistant Metal Materials?October 30, 2023Corrosion-resistant metals are used in a wide range of applications, from the culinary industry to aerospace applications. Like most metals, they provide structural strength and heat resistance, but the metals listed in this article are also more resistant to corrosion than others.view The Comprehensive Guide to Sheet Metal Thickness Gauge 2024January 22, 2024What is metal gauge thickness? This article explains everything you need to know about the use of sheet metal gauge thickness.view

The Comprehensive Guide to Sheet Metal Thickness Gauge 2024January 22, 2024What is metal gauge thickness? This article explains everything you need to know about the use of sheet metal gauge thickness.view An Introduction to Metal Fabrication: Benefits, Methods & ApplicationsDecember 7, 2023This article introduces sheet metal fabrication in detail. As a versatile metal production technique, it shows extensive applications across numerous industries.view

An Introduction to Metal Fabrication: Benefits, Methods & ApplicationsDecember 7, 2023This article introduces sheet metal fabrication in detail. As a versatile metal production technique, it shows extensive applications across numerous industries.view How to Reduce the Cost of CNC Machined Parts Through Structural DesignOctober 20, 2023CNC machined parts, i.e. parts processed by CNC equipment, CNC machining, usually refers to the precision machining method digitally controlled by a computer, which has become a common method of machining in nowadays.view

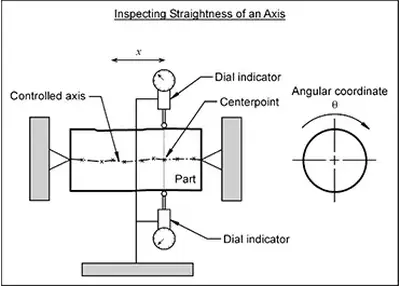

How to Reduce the Cost of CNC Machined Parts Through Structural DesignOctober 20, 2023CNC machined parts, i.e. parts processed by CNC equipment, CNC machining, usually refers to the precision machining method digitally controlled by a computer, which has become a common method of machining in nowadays.view Unlocking Precision in CNC Machining: Understanding Straightness and FlatnessNovember 17, 2023As a leading precision machine shop, Richconn stands committed to delivering unrivaled precision and excellence in every aspect of our work. Dive into the world of geometric accuracy with us as we explore the pivotal concepts of "straightness" and "flatness" in CNC machining.view

Unlocking Precision in CNC Machining: Understanding Straightness and FlatnessNovember 17, 2023As a leading precision machine shop, Richconn stands committed to delivering unrivaled precision and excellence in every aspect of our work. Dive into the world of geometric accuracy with us as we explore the pivotal concepts of "straightness" and "flatness" in CNC machining.view

EN

EN

ru

ru