While there are roughly 90 naturally occurring elements, the majority are metals. However, metals alone may not always be ideal for our needs. For example, iron is incredibly strong but can be brittle and susceptible to rust in damp environments. But alloy did not have these disadvantages. This is why many of the materials we use are alloys. So, what does alloy mean? The definition of alloying is the combination of metals with other substances to enhance their strength, hardness, lightness, or other properties. Alloys are ubiquitous in our surroundings. Let's delve deeper into alloys definition and start your CNC journey!

In the realm of chemistry, it is important to understand what is a alloy. Definition alloy is that a blend of multiple metals or a metal mix with one or more additional elements, compared to defined unalloyed. The amalgamation of these constituents gives rise to an alloy that possesses distinct properties that differ from the original elements. These properties often include enhanced strength and hardness. For instance, when elemental iron is combined with non-metallic silicon or carbon, the resulting alloy is steel or silicone steel respectively.

Having gained an understanding of the definition of an alloy, let us delve into the constituents that form such materials. An alloy comprises two or more elements, which can exist either as a compound or a solution. Typically, the components of alloys are predominantly metals, with carbon being an exceptional case as a non-metal yet being a significant constituent of steel. The production of alloys usually involves melting the mixture of its constituents. This melting process allows for the blending and homogenization of the elements, resulting in the formation of a unified alloy with distinct properties and characteristics.

Once you have familiarized yourself with whats an alloy is, exploring it becomes a more feasible task. Define alloyed as a substance that possesses metallic properties and is composed of two or more elements, of which at least one is a metal. In this context, a metal is a material that exhibits characteristic metallic properties, such as a lustrous appearance when freshly made, fractured, or polished. Additionally, metals are known for their ability to conduct heat and electricity.

Metals, in their pure form, exhibit specific characteristics such as malleability, allowing them to be easily shaped into thin sheets through hammering, and ductility, enabling them to be drawn into wires. However, most pure metals tend to be too brittle, soft, or chemically reactive to be practical for various applications.

To overcome these limitations, metals can be combined in different ratios to form alloys, such as alluminum alloy. The mechanical properties of commercially pure aluminum (99-99.6%) are enhanced, resulting in increased hardness and strength, by the presence of impurities, particularly silicon (Si) and iron (Fe). However, when aluminum is alloyed, it becomes heat-treatable, leading to substantial modifications in its mechanical characteristics.

When examining a metal under a high-powered electron microscope, the internal arrangement of atoms can be observed in a consistent pattern known as a crystalline lattice. It can be likened to a cardboard box filled with marbles. In the case of an alloy, in addition to the atoms of the main metal, there are scattered atoms of alloying agents dispersed within the lattice structure.

When atoms of the main metal are substituted by alloying agent atoms, a type of alloy known as a substitution alloy is formed. The formation of such an alloy relies on the compatibility of the atomic sizes between the base metal and the alloying agent. Typically, the constituent elements in substitution alloys are situated close to each other in the periodic table. Take brass as an example, which is a substitution alloy based on copper. In brass, atoms of zinc substitute approximately 10-35 percent of the atoms that would normally be present in copper. The success of brass as an alloy stems from the close proximity of copper and zinc in the periodic table, as well as their similar atomic sizes.

Definition alloys can also be created when the alloying agent, or multiple agents, consist of atoms significantly smaller than those of the main metal. In such instances, the smaller agent atoms can fit into the gaps or interstices between the atoms of the main metal. This type of alloy is referred to as an interstitial alloy. An example of an interstitial alloy is steel, where a relatively small quantity of carbon atoms slip into the interstices amidst the large atoms present in the crystalline lattice structure of iron.

There is an extensive array of alloys utilized for countless purposes. In the table below, we have an example of an alloy and other common intriguing alloys. It is important to note that each alloy can have numerous variations, and the precise composition can vary significantly. Consequently, the percentage values provided in different sources may not always align precisely.

Alloy | Components | Typical uses |

Alnico | Iron (50%+) + aluminum (8–12%) + nickel (15–25%), cobalt (5–40%), + other metals such as copper and titanium. | Magnetic components are found in loudspeakers and electric guitar pickups. |

Amalgam | Mercury (45–55%) + silver, tin, copper, and zinc. | Dental fillings. |

Copper (65–90%), zinc (10–35%). | Examples of items that utilize door locks, bolts, brass musical instruments, and central heating pipes. | |

Bronze | Copper (78–95%) + tin (5–22%) + manganese, phosphorus, aluminum, or silicon. | Decorative statues, and musical instruments. |

Cast iron | Iron (96–98%) + carbon (2–4%) + silicon. | Metal constructions like bridges and durable cookware. |

Nitinol | Nickel (50–55%) + titanium (45–50%). | Shape-memory alloy finds applications in medical devices, spectacle frames that regain their original shape, and temperature-sensitive switches. |

Pewter | Tin (80–99%) + copper, lead, antimony. | Ornaments were traditionally employed in the production of tableware before the widespread adoption of glass materials. |

Sterling silver | Silver (92.5%) + copper (7.5%). | Cutlery, jewelry, medical tools, musical instruments. |

18k Gold | Gold (75%) + palladium (17%), silver (4%) + copper (4%) | Jewelry. |

Stellite | Cobalt (67%) + chromium (28%) + tungsten (4%) + nickel (1%) | A protective coating is often utilized for cutting tools like saw teeth, lathes, and chainsaws. |

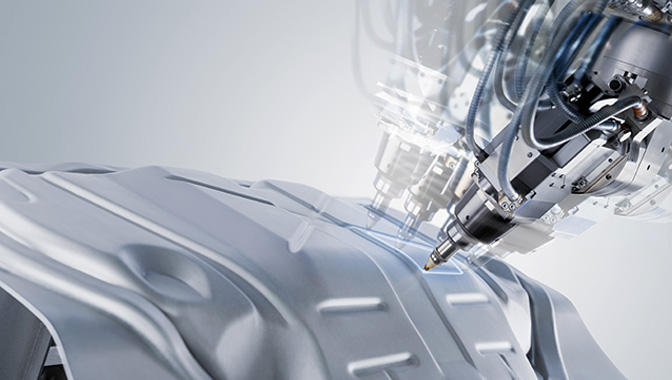

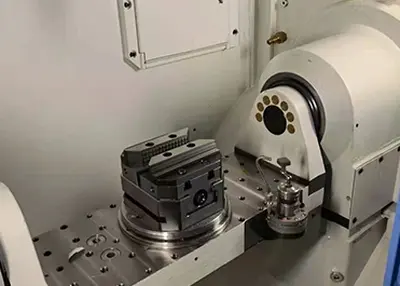

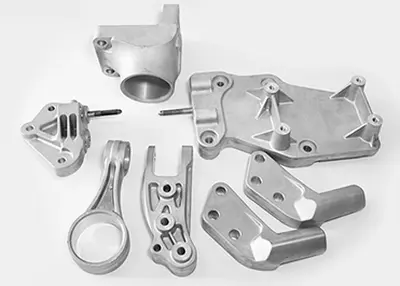

Alloy steel possesses a wide range of mechanical properties that make it ideal for applications requiring high strength, toughness, and wear resistance. As an essential material in modern manufacturing, alloys play a crucial role. Whether you need top-quality steel materials or you’re seeking expert metal fabrication services, Richconn provides the best solutions at competitive prices. Our expertise lies in providing top-notch CNC machining services, encompassing CNC milling and turning, with a comprehensive selection of materials available.

7 Applications of CNC Machining Medical Parts ManufacturingOctober 25, 2023The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries.view

7 Applications of CNC Machining Medical Parts ManufacturingOctober 25, 2023The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries.view What Is Zinc Alloy? The Complete Basics to Get StartedOctober 8, 2023This article covers the information you need to watch out for in product design and part manufacturing when using zinc alloy. Take a deeper look into zinc alloy!view

What Is Zinc Alloy? The Complete Basics to Get StartedOctober 8, 2023This article covers the information you need to watch out for in product design and part manufacturing when using zinc alloy. Take a deeper look into zinc alloy!view What Is High Carbon Steel? What Is the Difference Between High Carbon Steel Sk2, Sk4, Sk5, Sk7, Etc.?October 27, 2023High carbon steel is a type of steel with a carbon content between 0.6% and 1.7%, which contains much more carbon than ordinary carbon steel, and is therefore also caled carbon tool steel. High carbon steel has high hardness, high strength, low toughness, and is easy to quench and temper, so it is widely used in the manufacture of machine parts, tools and blades that require high strength and hardness.view

What Is High Carbon Steel? What Is the Difference Between High Carbon Steel Sk2, Sk4, Sk5, Sk7, Etc.?October 27, 2023High carbon steel is a type of steel with a carbon content between 0.6% and 1.7%, which contains much more carbon than ordinary carbon steel, and is therefore also caled carbon tool steel. High carbon steel has high hardness, high strength, low toughness, and is easy to quench and temper, so it is widely used in the manufacture of machine parts, tools and blades that require high strength and hardness.view What five axes does the five axes machining center have?March 6, 2023Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position ...view

What five axes does the five axes machining center have?March 6, 2023Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position ...view Unlocking Creativity: Exploring the World of CNC Acrylic MachiningNovember 15, 2023Welcome to the realm where precision meets creativity, where the art of CNC (Computer Numerical Control) technology converges with the transparent beauty of acrylic. In this journey, we will delve into the intricate world of CNC Acrylic machining, unveiling its applications, design inspirations, material synergies, and real-world case studies.view

Unlocking Creativity: Exploring the World of CNC Acrylic MachiningNovember 15, 2023Welcome to the realm where precision meets creativity, where the art of CNC (Computer Numerical Control) technology converges with the transparent beauty of acrylic. In this journey, we will delve into the intricate world of CNC Acrylic machining, unveiling its applications, design inspirations, material synergies, and real-world case studies.view The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view

The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view

EN

EN

ru

ru