Mechanical testing is a series of tests used to determine the mechanical properties of a material as it performs in a particular environment. Mechanical properties are the characteristics that describe how a material behaves and responds when subjected to different types of forces and deformations, such as stress, strain, load, temperature, speed, time, etc. Mechanical testing is important for material identification, characterization, selection, and validation, as it can ensure the quality, safety, and reliability of materials and products.

Used to measure the tensile strength, yield strength, modulus of elasticity, ductility, and other properties of a material when stretched by a pulling force.

Used to measure the compressive strength, yield strength, modulus of elasticity, and other properties of a material when squeezed by a pushing force.

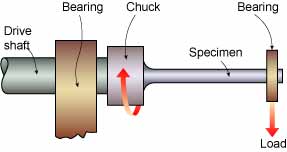

Used to measure the shear modulus, shear strength, and other properties of a material when twisted by a twisting force.

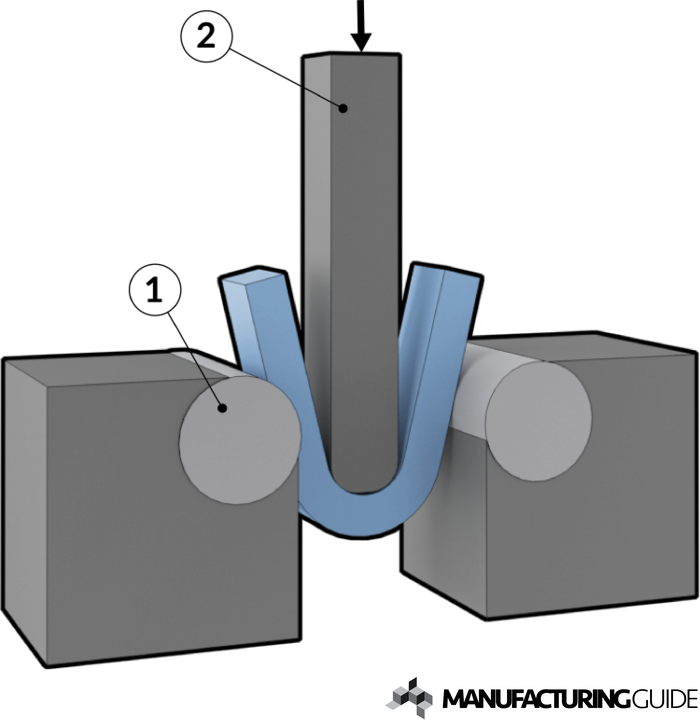

Used to measure the bending modulus, bending strength, and other properties of a material when bent by a bending force.

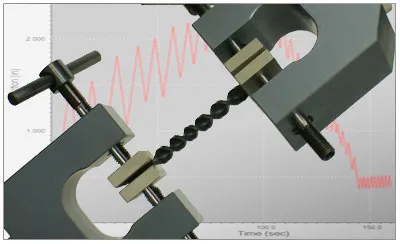

Used to measure the fatigue life, fatigue strength, and other properties of a material when subjected to repeated or cyclic loading.

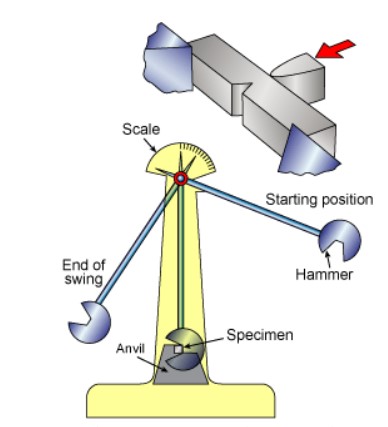

Used to measure the impact energy, impact toughness, and other properties of a material when struck by a sudden or dynamic force.

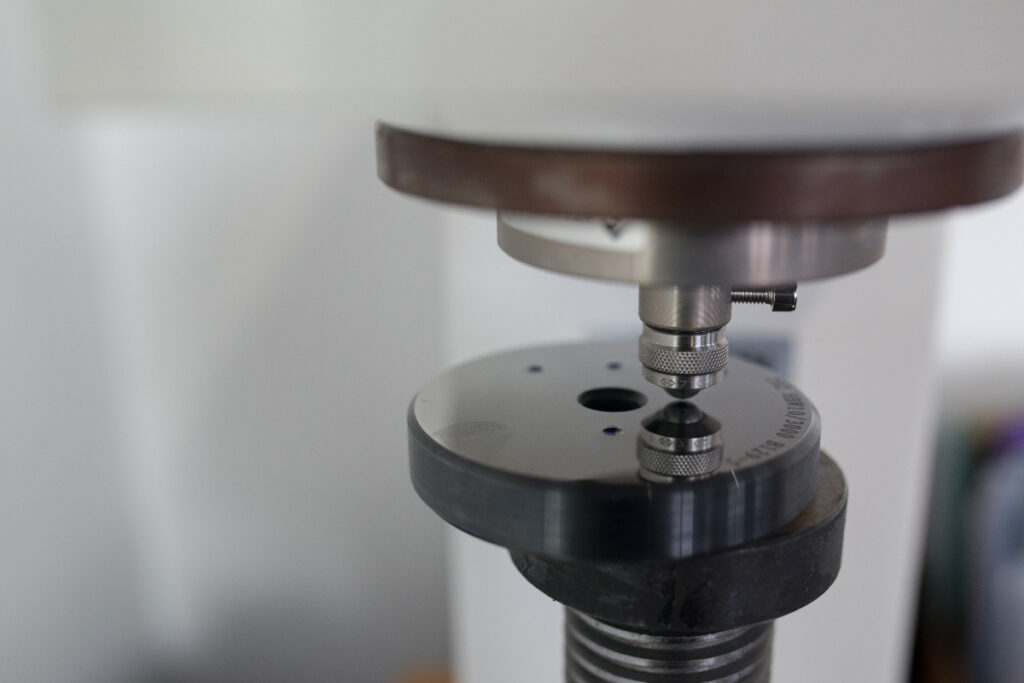

Used to measure the hardness, or the resistance to indentation, of a material when pressed by a hard object.

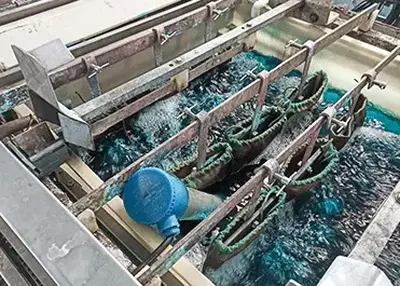

Used to measure the corrosion resistance, or the resistance to chemical or electrochemical attack, of a material when exposed to a corrosive environment.

Mechanical properties are the characteristics that describe how a material behaves and responds when subjected to different types of forces and deformations, such as stress, strain, load, temperature, speed, time, etc. Mechanical properties are important for determining the performance and suitability of materials for different applications, as they can indicate the strength, durability, flexibility, and reliability of materials and products.

• Strength: the ability of a material to resist deformation or failure when subjected to an external force, such as tensile strength, compressive strength, shear strength, etc.

• Hardness: the ability of a material to resist indentation or abrasion when pressed by a hard object, such as Brinell hardness, Vickers hardness, Rockwell hardness, etc.

• Toughness: the ability of a material to absorb energy and resist fracture when subjected to an impact or a dynamic force, such as Charpy impact toughness, Izod impact toughness, fracture toughness, etc.

• Elasticity: the ability of a material to return to its original shape and size after being stretched or compressed by an elastic force, such as modulus of elasticity, Young's modulus, bulk modulus, etc.

• Plasticity: the ability of a material to retain its shape and size after being permanently deformed by a plastic force, such as yield strength, ultimate strength, ductility, etc.

• Brittleness: the tendency of a material to fracture or shatter without significant deformation or energy absorption when subjected to a force, such as fracture stress, fracture strain, etc.

Different materials have different mechanical properties, depending on their composition, structure, and processing. For example, metals are generally strong, hard, tough, and ductile, but they may also be brittle, soft, or weak, depending on their alloying elements, grain size, heat treatment, etc. Plastics are generally flexible, lightweight, and corrosion-resistant, but they may also be brittle, flammable, or degradable, depending on their polymer type, molecular weight, additives, etc. Ceramics are generally hard, wear-resistant, and heat-resistant, but they may also be brittle, porous, or fragile, depending on their material type, sintering temperature, porosity, etc.

Mechanical testing methods are the procedures and techniques used to measure the mechanical properties of materials by applying different types of forces and deformations, such as stress, strain, load, temperature, speed, time, etc. Mechanical testing methods can be performed using different types of equipment and instruments, depending on the purpose and the material of the test. Some of the common equipment and instruments are:

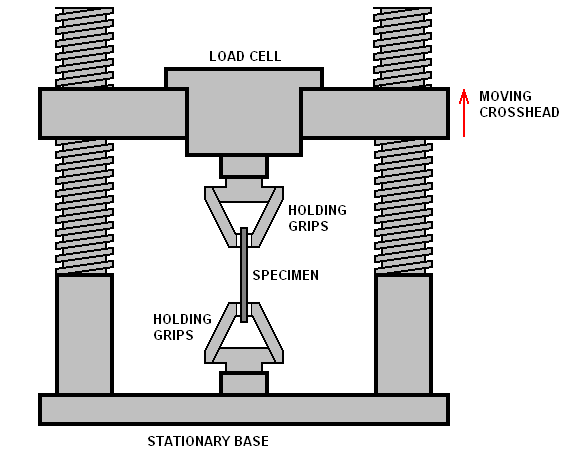

• Universal testing machine: a device that can apply various types of forces, such as tensile, compressive, bending, or torsional, to a material specimen, and measure the resulting deformation, strain, or displacement.

• Impact testing machine: a device that can apply a sudden or dynamic force, such as a hammer or a pendulum, to a material specimen, and measure the resulting energy, velocity, or displacement.

• Hardness tester: a device that can apply a hard object, such as a ball, a cone, or a diamond, to a material specimen, and measure the resulting indentation, depth, or area.

• Corrosion tester: a device that can expose a material specimen to a corrosive environment, such as a salt spray, a humid atmosphere, or an electrochemical cell, and measure the resulting weight loss, potential, or current.

Some of the common mechanical testing methods and how to perform them and interpret the results and data are:

Tensile testing is a mechanical testing method that is used to measure the tensile strength, yield strength, modulus of elasticity, ductility, and other properties of a material when stretched by a pulling force. Tensile testing can be performed using a universal testing machine, which can apply a controlled and increasing tensile force to a material specimen, and measure the resulting elongation, strain, or displacement.

To perform tensile testing, you need to follow these steps:

• Prepare the material specimen according to the standard or the specification, such as the shape, size, surface, and orientation of the specimen, and mark the gauge length and the cross-sectional area of the specimen.

• Mount the specimen on the universal testing machine, and attach the extensometer or the strain gauge to the specimen, and make sure the specimen is aligned and secured, and does not slip or rotate during the test.

• Set the parameters of the test, such as the speed, the load, the strain, and the data acquisition rate of the universal testing machine, and start the test.

• Record the data and the results of the test, such as the load, the displacement, the strain, and the stress of the specimen, and plot the stress-strain curve of the specimen.

• Analyze the data and the results of the test, such as the tensile strength, the yield strength, the modulus of elasticity, the ductility, and the fracture mode of the specimen, and calculate the values and the ratios of these properties.

• Choose the appropriate type and size of the universal testing machine and the specimen for your material and your testing needs, such as the capacity, the resolution, and the accuracy of the universal testing machine, and the shape, size, surface, and orientation of the specimen.

• Perform the test with care and caution, as the specimen may break or snap during the test, and avoid touching or interfering with the specimen or the universal testing machine, as this may affect the accuracy and validity of the test.

• Interpret the results and the data of the test with reference to the standard or the specification, such as the ASTM, ISO, DIN, etc., and compare the results and the data with the expected or the required values and ranges of the properties.

Mechanical testing standards are the rules and guidelines that specify the procedures, methods, equipment, and criteria for conducting mechanical testing and reporting the results and data. Mechanical testing standards are necessary for ensuring the quality, safety, and reliability of materials and products, as they can provide consistency, accuracy, and comparability of the testing process and the testing outcome.

• ASTM: the American Society for Testing and Materials, which is an international organization that develops and publishes standards for materials, products, systems, and services, such as ASTM E8/E8M for tensile testing, ASTM E23 for impact testing, ASTM E18 for hardness testing, etc.

• ISO: the International Organization for Standardization, which is an international organization that develops and publishes standards for various fields and sectors, such as ISO 6892-1 for tensile testing, ISO 148-1 for impact testing, ISO 6506-1 for hardness testing, etc.

• DIN: the Deutsches Institut für Normung, which is the German national standards organization that develops and publishes standards for various fields and sectors, such as DIN EN ISO 6892-1 for tensile testing, DIN EN ISO 148-1 for impact testing, DIN EN ISO 6506-1 for hardness testing, etc.

• Aerospace: the industry that deals with the design, development, production, and operation of aircraft and spacecraft, such as airplanes, helicopters, rockets, satellites, etc. Mechanical testing standards and applications are important for aerospace, as they can ensure the safety, reliability, and durability of the materials and products that are exposed to high stress, high temperature, high speed, and high altitude conditions, such as ASTM E8/E8M for tensile testing, ASTM E23 for impact testing, ASTM E18 for hardness testing, etc.

• Automotive: the industry that deals with the design, development, production, and operation of vehicles and transportation systems, such as cars, trucks, buses, trains, etc. Mechanical testing standards and applications are important for automotive, as they can ensure the quality, efficiency, and performance of the materials and products that are subjected to various loads, vibrations, impacts, and corrosions, such as ISO 6892-1 for tensile testing, ISO 148-1 for impact testing, ISO 6506-1 for hardness testing, etc.

• Biomedical: the field that applies the principles and methods of engineering and biology to the development and improvement of medical devices and systems, such as implants, prosthetics, pacemakers, etc. Mechanical testing standards and applications are important for biomedical, as they can ensure the compatibility, functionality, and biostability of the materials and products that are in contact with the human body and its fluids, such as DIN EN ISO 6892-1 for tensile testing, DIN EN ISO 148-1 for impact testing, DIN EN ISO 6506-1 for hardness testing, etc.

• Construction: the industry that deals with the design, development, production, and operation of buildings and structures, such as houses, bridges, dams, etc. Mechanical testing standards and applications are important for construction, as they can ensure the strength, stability, and durability of the materials and products that are exposed to various loads, weather, and environmental conditions, such as ASTM E8/E8M for tensile testing, ASTM E23 for impact testing, ASTM E18 for hardness testing, etc.

Mechanical testing is a valuable and essential tool for material science and engineering, as it can provide useful and reliable information and data about the performance and suitability of materials and products for different purposes and environments. Mechanical testing can help us to understand and improve the mechanical properties of materials, and to design and develop better and safer materials and products.

When you need high-quality products made from tested materials, Richconn is your choice. We are committed to providing products made from proven materials and providing you with metal CNC machining services to ensure you receive reliable and quality solutions. No matter what product or material you need, we can provide you with professional help and support so you can feel confident choosing Richconn.

Cleaning Machined Parts: A Comprehensive Guide to Elevate CNC Machining QualityNovember 13, 2023Welcome to Richconn, where precision meets perfection in CNC machining. In the world of machining, ensuring the cleanliness of machined parts is not just a step; it's a commitment to excellence.view

Cleaning Machined Parts: A Comprehensive Guide to Elevate CNC Machining QualityNovember 13, 2023Welcome to Richconn, where precision meets perfection in CNC machining. In the world of machining, ensuring the cleanliness of machined parts is not just a step; it's a commitment to excellence.view 2023 ShenZhen International Industrial Automation Robot ExhibitionMarch 6, 20232023 ShenZhen International Industrial Automation Robot ExhibitionThe 12th ShenZhen International Industrial Automation and Robot ExhibitionCome back to ShenZhen in 2023 to write a new chapter of inte...view

2023 ShenZhen International Industrial Automation Robot ExhibitionMarch 6, 20232023 ShenZhen International Industrial Automation Robot ExhibitionThe 12th ShenZhen International Industrial Automation and Robot ExhibitionCome back to ShenZhen in 2023 to write a new chapter of inte...view How to Use a Five Axis Machining Center to Process Titanium Alloy Shaped PartsMarch 24, 2023As a five-axis machining center engineer, I will share with you the methods of machining titanium alloy special-shaped parts using a five-axis machining center, as well as the key points of titanium a...view

How to Use a Five Axis Machining Center to Process Titanium Alloy Shaped PartsMarch 24, 2023As a five-axis machining center engineer, I will share with you the methods of machining titanium alloy special-shaped parts using a five-axis machining center, as well as the key points of titanium a...view CNC Machined Bicycle Parts: Elevate Your Cycling Experience with Richconn PrecisionNovember 13, 2023In the realm of cycling, precision matters. Every curve, every gear, and every component plays a crucial role in enhancing the rider's experience. That's where Richconn comes in – a name synonymous with excellence in CNC machining for bicycle parts.view

CNC Machined Bicycle Parts: Elevate Your Cycling Experience with Richconn PrecisionNovember 13, 2023In the realm of cycling, precision matters. Every curve, every gear, and every component plays a crucial role in enhancing the rider's experience. That's where Richconn comes in – a name synonymous with excellence in CNC machining for bicycle parts.view Inconel 718: A Superalloy with Lasting RelevanceOctober 12, 2023Metal 3D printing has finally catapulted Inconel, the classic nickel-based heat-resistant alloy, into the 21st century. Inconel 718, the hardened version of Inconel 625, is the latest addition to our growing range of metals for Direct Metal Laser Sintering (DMLS).view

Inconel 718: A Superalloy with Lasting RelevanceOctober 12, 2023Metal 3D printing has finally catapulted Inconel, the classic nickel-based heat-resistant alloy, into the 21st century. Inconel 718, the hardened version of Inconel 625, is the latest addition to our growing range of metals for Direct Metal Laser Sintering (DMLS).view Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view

Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view