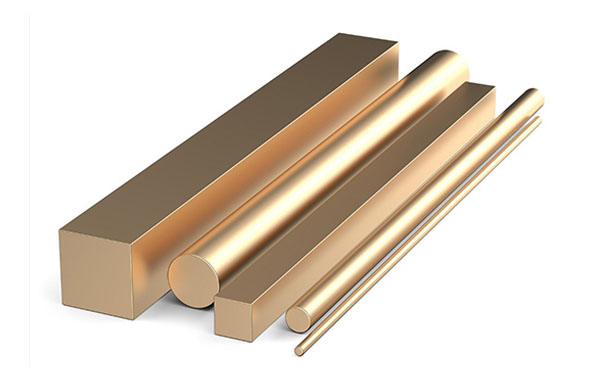

Brass is an alloy metal that is made of copper and zinc. Bronze and copper are similar to brass. Differences in bronze vs brass vs copper are very subtle. Parts designers may easily get confused about what's the difference between bronze and brass and how to tell the difference between copper and brass.

Although there is a slight color difference, you may not be able to tell the metals apart right away. The most difficult element is that you cannot select just one of them for your applications. Despite their many commonalities, they also have several distinctive features. As a result, brass may be unsuitable for several applications where copper is commonly utilized. This article brings you a detailed comparison that will establish how to tell brass from bronze and the difference between brass and copper. In this article, we will also discuss the differences between the available alloys, uses, and much more. The information provided here will assist you in making the best metal choices for your metal projects.

These metals, as we have previously discovered, differ from one another in a variety of ways. To make these distinctions easier for you to understand, we will divide them into separate sections.

Alloy 260

Alloy 260, also known as cartridge brass, is highly suitable for cold working. It finds applications in automobiles, ammunition, hardware, and fasteners.

Alloy 272

Alloy 272, commonly referred to as yellow brass, contains around 33% zinc and is primarily used in industrial settings.

Alloy 330

Alloy 330 is valued for its high machinability and low lead content, making it ideal for cold working. Many manufacturers choose this alloy for piping applications.

Alloy 353

Alloy 353, known as clock brass, is highly machinable and is often used in the fabrication of precision clock parts.

Alloy 360

Alloy 360 is the most common brass grade available. It offers excellent formability, and machinability, and is commonly used in brazing, soldering, fittings, fasteners, valves, and various hardware components.

Alloy 464

Alloy 464, also called naval brass, is renowned for its outstanding corrosion resistance and ability to withstand temperature variations. It is suitable for applications involving cold and hot forming processes, bending, soldering, welding, and more.

Alloy 932

This bronze alloy contains a high level of lead and is used for making non-pressure components such as washers and bushings.

Alloy 954

An aluminum bronze alloy that is commonly used in industrial and mounting equipment, and it is suitable for a wide range of environments.

Alloy 101

This copper alloy is oxygen-free and is ideal for applications that require high ductility and electrical conductivity.

Alloy 110

Also known as electrolytic (ETP) copper, it has the highest thermal and electrical conductivity among copper alloys. It is also highly ductile and malleable.

Alloy 122

Similar to Alloy 110 in terms of mechanical properties, it has superior weldability and formability.

Alloy 145

Known as tellurium copper, it contains about 0.7 percent tellurium. Like other copper alloys, it has excellent electrical and thermal conductivity, as well as machinability and formability.

Understanding the differences in material properties will help you better decide between copper vs brass vs bronze. The following provides you with detailed information about the difference between bronze and brass and the difference between copper and brass.

Is brass the same as bronze? Brass and bronze are both bronze-based alloys, but there are some differences between them. Here are some key differences between brass and bronze:

1. Bronze vs Brass: Element Composition

Brass is an alloy of copper and zinc, while bronze is an alloy of copper. The main difference between brass and bronze is the presence of zinc or tin in the alloy.

2. Brass vs Bronze: Corrosion Resistance

Bronze has better corrosion resistance than brass. Bronze, an alloy of copper, often oxidizes upon exposure to air. Thus, it forms a protective layer (mottled patina). As a result, bronze is adequately prevented from corrosion. Environments with salt water are resistant to bronze. It is therefore incredibly helpful for nautical applications and boat fittings. However, brass is more likely to be corroded by acids and alkalis, and its color may change after long-term use in a corrosive environment.

3. Brass Versus Bronze: Weight

Bronze is heavier than brass. The density of bronze is higher than that of brass, which means that bronze has a higher weight per unit volume. This is why bronze is often used for larger objects such as doors, windows, and dishes, while brass is often used for smaller objects such as buttons, screws, and watchbands.

4. Brass and Bronze: Durability

Both brass and bronze have good durability, but Bronze is a hard, durable substance that resists bending. It is highly durable and has a strong resistance to corrosion. However, brass may be vulnerable to splitting and cracking due to its higher coefficient of friction.

5. Brass vs. Bronze: Machinability:

Both brass bronzes can be machined, but bronze has better machinability. Bronze is a considerably more durable and robust metal that does not bend easily. Bronze can be machined with less effort and with better accuracy than brass. This is because bronze has a lower coefficient of friction and can be machined more easily.

6. Bronze Brass: Weldability

Brass alloys can be used for silver soldering, TIG, and MIG welding. Lead-containing alloys, however, are more challenging to weld. Basically, alloys with less zinc guarantee simpler welding. Unleaded bronze has a decent weldability among the grades of bronze. However, they frequently fracture under pressure, and the ideal method might be SMAW.

Is brass copper? The differences between brass and copper are as follows:

1. Brass vs Copper: Element Composition

Brass is an alloy of copper and zinc, typically with a copper content of 60% to 90%. Copper, on the other hand, is a pure element and a naturally occurring metal.

2. Copper vs Brass: Corrosion Resistance

Brass is more resistant to corrosion than copper due to its alloy composition. Copper, being a pure metal, is more susceptible to oxidation and corrosion.

3. Brass and Copper: Weight

Copper is heavier than brass due to its density, which is approximately 8.9 times greater than brass. Brass, being an alloy, has a lower density and is therefore lighter.

4. Copper and Brass: Durability

Brass is more durable than copper due to its mechanical properties and ability to withstand wear and tear. Copper, being soft, is more prone to damage and wear over time.

5. Brass Copper: Machinability

Copper is easier to machine than brass due to its softness and malleability. Brass, being harder, is more difficult to machine but can be machined with appropriate tools.

6. Copper Brass: Weldability

Brass is more difficult to weld than copper due to its alloy composition and higher melting point. Copper has a lower melting point and is therefore easier to weld.

You can choose the best option for your applications using the differences in electrical and thermal conductivity.

Is bronze the same as brass? Actually, bronze and brass are two different types of metal alloys, now we will discuss how to identify between brass and bronze.

1. Electrical Conductivity

Bronze has lower electrical conductivity than brass. Brass is a better conductor of electricity, making it suitable for electrical applications such as fittings and connectors.

2. Thermal Conductivity

Brass also exhibits higher thermal conductivity compared to bronze. This property makes brass a preferred choice in applications where heat dissipation is required, like heat exchangers and radiators.

Copper and brass are two distinct metallic materials with notable differences in their properties:

1. Electrical Conductivity

Copper is an excellent conductor of electricity, with the highest electrical conductivity among common metals, making it ideal for electrical wiring and transmission lines. Brass, on the other hand, has lower electrical conductivity compared to copper.

2. Thermal Conductivity

Copper is also highly efficient in conducting heat, making it a preferred choice in various heat exchange applications. Brass has slightly lower thermal conductivity than copper.

You must consider a material's strength while choosing the applications that are best for it. As a result, while contrasting copper brass bronze, you must take this issue into account.

1. Tensile Strength

Bronze is commonly used in applications where metal strength is required. This is due to its tensile strength ranging from 350 to 635 MPa. Brass is next, with an ultimate tensile strength ranging from 338 to 469 MPa.

2. Yield Strength

The yield strength of bronze is superior to that of both brass and copper. Bronze's yield strength ranges from 125 to 800 MPa, surpassing brass which has a yield strength between 95 and 124 MPa. Among the three, copper has the lowest yield strength, at just 33.3 MPa.

1. Tensile Strength

Compared to brass, copper's tensile strength is relatively lower and copper has a tensile strength of 210 MPa., which makes brass more appropriate for use in circumstances that demand greater strength, such as in the manufacturing of plumbing fittings.

2. Yield Strength

Like tensile strength, brass usually has a superior yield strength compared to copper. Copper possesses the least yield strength at 33.3 MPa. Yield strength is defined as the force necessary to cause permanent deformation in the metal.

It's essential that your chosen material meets specific standards for its ability to be shaped or formed. Therefore, making an accurate selection is critically important.

1. Formability

An excellent illustration is PB1 phosphor bronze, which is highly suitable for cold forming. Conversely, brass presents challenges in terms of forming due to its limited flexibility. Melting Point

2. Melting Point

The formability of a material is often influenced by its melting point, with lower melting points generally indicating higher formability. Bronze has a slightly lower melting point of 913 °C, while brass has a melting point of 927 °C.

1. Formability

Copper has excellent formability, allowing it to be easily shaped and fabricated into various forms. Brass also possesses good formability and can be molded into intricate designs, offering more flexibility in applications that require complex shapes.

2. Melting Point

Copper has a higher melting point than brass. This characteristic makes copper more suitable for applications requiring high-temperature resistance or thermal stability.

Distinguishing between brass, bronze, and copper can be challenging due to their similar appearances. Nonetheless, there are some subtle distinctions that should be acknowledged such as bronze vs brass color, brass vs copper color, and the hardness of these three metals.

1. Color

Distinguishing between bronze vs brass may be easy with their color. Brass comes in a subdued yellowish-gold color, similar to a plain stone. This makes brass a perfect material for fittings. On the other hand, bronze has a somewhat reddish-brown color. And bronze’s reddish-brown has a dull gold shade.

2. Hardness

Brass has a hardness range of 55 to 73, while bronze falls between 40 and 420 on the hardness scale. This indicates that bronze is the harder of the two metals. Furthermore, bronze is also more brittle, making it more susceptible to fractures or breakages.

1. Color

Copper has a distinct reddish-orange color, while brass is typically yellowish or golden in appearance. The color difference arises due to variations in the compositions of the materials.

2. Hardness

Copper scores 35 on the Brinell hardness scale. Copper has a distinct reddish-orange color, while brass is typically yellowish or golden in appearance. The color difference arises due to variations in the compositions of the materials.

Brass, bronze, and copper are commonly available in various grades, resulting in differences in their prices. Generally, copper is more expensive compared to brass and bronze. The reduced price of bronze can be attributed to its lower copper content in the alloy. Similarly, brass is the least expensive due to its higher zinc content. As zinc is cheaper than copper, the overall cost of brass is reduced.

Richconn offers professional industrial metal fabrication services at competitive prices and with fast lead times. Feel free to email your design files to initiate your project!

While these metals are suitable for several similar applications, there are some peculiarities. Here are some important applications of brass, bronze, and copper.

Brass is widely recognized for its aesthetic appeal and decorative qualities, making it a popular choice in various industries.

Its excellent machinability and workability make it well-suited for applications in plumbing and piping systems.

Brass is commonly utilized in the manufacturing of fittings, such as connectors and valves.

The electrical conductivity of brass makes it suitable for use in electronics and electrical terminals.

Brass is frequently used in the production of musical instruments, thanks to their unique tonal properties.

Clock and watch components, such as gears and frames, often employ brass due to its durability and corrosion resistance.

Bronze metal sheets are commonly utilized in a variety of industrial applications:

One of the key uses of bronze is in the production of bushings and bearings for automobile transmissions.

In the marine industry, bronze is favored for its corrosion resistance and is employed in the manufacturing of components such as propellers, ship fittings, and boat fixtures.

Bronze is also used in the production of electrical connectors and electric motors.

Its durability and resilience make bronze an ideal material for the fabrication of springs.

In the petrochemical sector, bronze finds applications in components and tools used in oil rigs.

Copper offers numerous advantages, including exceptional machinability, formability, and conductivity, making it highly valuable across a wide range of industries. Here are a few notable applications of copper:

Copper is commonly utilized in the production of electric motors due to its excellent electrical conductivity.

In the telecommunications industry, copper is often used for manufacturing components such as cables and connectors.

Its high thermal conductivity makes copper well-suited for heat sinks and heat exchangers, which are used in various cooling applications.

Copper is employed in the production of vacuum tubes, which are used in electronic devices and amplifiers.

In submarines, copper is used in the construction of anti-biofouling components to resist the growth of marine organisms.

Copper's aesthetic appeal and durability make it a popular choice for architectural components, such as roofing, gutters, and decorative elements.

The commercial grades of brass, bronze, and copper demonstrate their significant demand in various industries, primarily because of their numerous advantageous properties.

1. Durability

Brass is a durable metal that can withstand corrosion and wear, making it suitable for long-lasting applications.

2. Anti-bacterial Properties

Brass has inherent antimicrobial properties, inhibiting the growth and spread of bacteria on its surface. This makes it a preferred choice for applications where hygiene is important, such as in healthcare settings.

3. Aesthetics

Brass has a unique and attractive golden color, providing a visually appealing and sophisticated appearance. It is often used in decorative items, architectural accents, and jewelry.

4. Machinability

Brass is highly machinable, allowing for ease of shaping, drilling, and cutting. This makes it a preferred material in manufacturing processes that require intricate or complex parts.

5. Thermal and Electrical Conductivity

Brass exhibits good thermal and electrical conductivity, making it suitable for applications requiring efficient heat transfer or electrical conduction, such as heat exchangers or electrical connectors.

Brass can achieve a variety of appealing surface finishes, including plating, polishing, or brushing. This versatility allows for customization and enhances its aesthetic appeal.

1. Corrosion and Fatigue Resistance

Bronze is known for its excellent resistance to corrosion, making it highly durable and suitable for long-term use in various environments. It also exhibits good resistance to fatigue, allowing it to withstand repeated stress and pressure.

2. High-Dimensional Precision

Bronze has good dimensional stability, making it capable of maintaining precise shapes and tolerances during manufacturing processes. This makes it suitable for applications that require high precision and accuracy.

3. High Thermal and Electrical Conductivity

Bronze displays good thermal and electrical conductivity, making it useful in applications that require efficient heat transfer or electrical conductivity.

4. Excellent Surface Finishes

Bronze can achieve a wide range of surface finishes, including polishing, patina, and corrosion-resistant coatings. This allows for versatile and attractive surface appearances, making it suitable for decorative and aesthetic applications.

1. Excellent Electrical Conductivity

Copper is renowned for its high electrical conductivity, making it an ideal choice for electrical wiring, power transmission, and electronic components.

2. High Thermal Conductivity

Copper has exceptional thermal conductivity, enabling it to efficiently transfer and dissipate heat. This property makes it valuable for applications such as heat sinks, heat exchangers, and electrical motors.

3. Corrosion Resistance

Copper exhibits excellent resistance to corrosion, making it suitable for use in various environments, including marine and industrial settings. It can withstand the effects of moisture and oxidation, ensuring long-term durability.

4. Antibacterial Properties

Copper possesses natural antimicrobial properties, meaning it can effectively inhibit the growth and spread of bacteria and other harmful microorganisms. This makes it beneficial for applications where hygiene is critical, such as in healthcare facilities and plumbing systems.

If you require further information about these metal materials or find yourself uncertain about the best choice for your needs, Richconn is here to assist you. With our expert advice, you can gain a competitive advantage in material selection. At Richconn, our team consists of highly skilled technicians and professional machinists who will guide you in selecting the most suitable material for your project. Moreover, we offer comprehensive manufacturing and prototyping services, including sheet metal fabrication, CNC machining, injection molding, and 3D printing. Get in touch with us today to begin your project!

Copper, brass, and bronze are distinct metals that possess a range of beneficial qualities, including conductivity, corrosion resistance, and machinability. As a result, metal sheets made from these materials are widely used in diverse industrial applications and environments.

Brass & Copper is proud to offer a wide array of these metals in plate, bar, and sheet formats. To explore our comprehensive collection of copper, brass, and bronze materials, please browse through our inventories. If you are interested in collaborating with us for your upcoming project, please do not hesitate to reach out to us or request a free quote today.

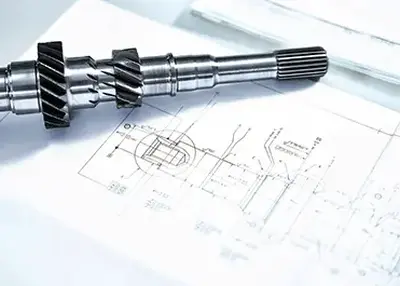

Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view

Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view Basic of Gear Manufacturing: A Guide to Learn about Gear Production ProcessesAugust 29, 2023There is no single process for manufacturing gear because several processes are required based on the type and application. The gears need to be in absolutely perfect condition to adapt to strenuous c...view

Basic of Gear Manufacturing: A Guide to Learn about Gear Production ProcessesAugust 29, 2023There is no single process for manufacturing gear because several processes are required based on the type and application. The gears need to be in absolutely perfect condition to adapt to strenuous c...view The Beginner's Guide to the 3D Printing ProcessMay 5, 2024This article explains what 3D printing is, the materials it uses, its advantages, processes and techniques, applications, and more. Read on and get the best custom 3D printing services.view

The Beginner's Guide to the 3D Printing ProcessMay 5, 2024This article explains what 3D printing is, the materials it uses, its advantages, processes and techniques, applications, and more. Read on and get the best custom 3D printing services.view Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view

Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view

How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view What are the characteristics of aerospace parts processingNovember 16, 2023The aerospace industry has always been one of the pinnacles of technology and engineering, and it relies on precision-manufactured aerospace parts to ensure highly reliable and safe aviation and space systems.view

What are the characteristics of aerospace parts processingNovember 16, 2023The aerospace industry has always been one of the pinnacles of technology and engineering, and it relies on precision-manufactured aerospace parts to ensure highly reliable and safe aviation and space systems.view