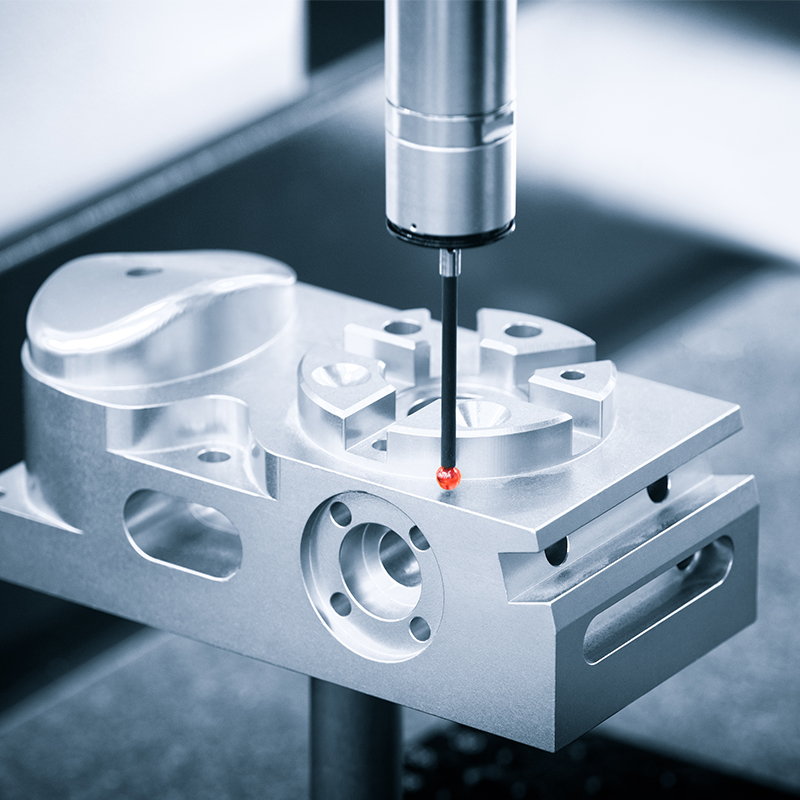

Is it possible to get perfection plus fast, low-cost prototypes and production parts from a CNC service provider?

The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.

Just as you consider various important issues when deciding whether to buy a car, you can make various considerations when designing milled and CNC turning parts. Such decisions can help speed up production and reduce costs.

In this article, we look at some decisions that will lead to optimizing your design for CNC machining. We look at depth and diameter of holes, thread sizes and types, marking on parts, wall heights and feature widths, lathes with live tools, and multiple milling operations.

There is great debate as to whether drills or end mills are better.

For fast production at lower cost, end mills offer greater flexibility in hole sizes per tool and also provide a better finish. They also allow the same tool to be used for slots and pockets, reducing cycle time and cost.

As a designer, you need to keep in mind that holes deeper than six diameters become problematic due to the limited length of the end mill. Deeper holes may require machining from both sides.

Check to see if your supplier uses a thread mill instead of cutting internal threads with a tap. This produces an accurate thread and the same milling tool can be used to cut threads of any size with the same pitch. This results in shorter setup and production times.

With only one tool, UNC and UNF threads from #2 to 1/2 inch and metric threads from M2 to M12 can be produced. Learn more about threads here.

When it comes to text, less is actually more if you want to save time and money. Are you wondering if you really need to have the part number, designation or logo milled into your parts?

If the answer is yes, the spacing between characters and the line width must be at least 0.5 mm. Use recessed rather than raised text and sans-serif fonts such as Arial or Verdana with a minimum font size of 20 point.

Wall heights and feature sizes are highly dependent on individual part geometry as well as the tool set used.

Even the hardest tools will deform, as will metal or plastic workpieces. So avoid very fine details and tall, thin walls. For example, the minimum feature thickness at Protolabs is 0.5 mm, and the maximum feature depth is 51 mm. However, this does not mean that these dimensions are suitable for the fins of a heat sink.

It pays to do careful research when outsourcing manufacturing, as there are significant differences in the capabilities of different companies, and therefore the opportunities.

For example, using similar tool sets as in other machining centers means that off-center holes, slots, flats and other features can be worked parallel or perpendicular to long axes of the turning piece. The same design rules are generally applied as for parts produced with machining centers.

The main difference in lathes with live tools is the shape of the raw material. Turned parts such as shafts and pistons are made from round stock, while milled parts such as manifold blocks, instrument housings and valve covers come from cube- or cuboid-shaped blocks.

I started this article with an analogy to buying a car. Here I would like to point out that progress in both CNC milling and car manufacturing is driven by technology. In the former case, that means you can get cheaper and better prototypes and production parts faster than you could just a few years ago. The prerequisite is that you thoroughly consider the design of your part, taking into account the capabilities and technical equipment of your precision machine works partner.

2023 ShenZhen International Industrial Automation Robot ExhibitionMarch 6, 20232023 ShenZhen International Industrial Automation Robot ExhibitionThe 12th ShenZhen International Industrial Automation and Robot ExhibitionCome back to ShenZhen in 2023 to write a new chapter of inte...view

2023 ShenZhen International Industrial Automation Robot ExhibitionMarch 6, 20232023 ShenZhen International Industrial Automation Robot ExhibitionThe 12th ShenZhen International Industrial Automation and Robot ExhibitionCome back to ShenZhen in 2023 to write a new chapter of inte...view What is Mechanical Testing & How to Test Mechanical Properties of MaterialsDecember 4, 2023Mechanical testing is a series of tests used to determine the mechanical properties of a material as it performs in a particular environment. Mechanical properties are the characteristics that describe how a material behaves and responds when subjected to different types of forces and deformations, such as stress, strain, load, temperature, speed, time, etc.view

What is Mechanical Testing & How to Test Mechanical Properties of MaterialsDecember 4, 2023Mechanical testing is a series of tests used to determine the mechanical properties of a material as it performs in a particular environment. Mechanical properties are the characteristics that describe how a material behaves and responds when subjected to different types of forces and deformations, such as stress, strain, load, temperature, speed, time, etc.view Electrophoretic Coating Process Details and Electrophoretic Paint Selection GuideJune 17, 2024Electrophoretic Coating is a cutting-edge technology that has revolutionized the manufacturing landscape. By offering consistent, uniform surface coverage along with unmatched durability and corrosion...view

Electrophoretic Coating Process Details and Electrophoretic Paint Selection GuideJune 17, 2024Electrophoretic Coating is a cutting-edge technology that has revolutionized the manufacturing landscape. By offering consistent, uniform surface coverage along with unmatched durability and corrosion...view What Is Prototype Manufacturing? Process, Benefits, and Vital TipsOctober 25, 2023A good understanding of prototype manufacturing will help you make the best choice for your project. Learn more about it from this passage.view

What Is Prototype Manufacturing? Process, Benefits, and Vital TipsOctober 25, 2023A good understanding of prototype manufacturing will help you make the best choice for your project. Learn more about it from this passage.view How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view

How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view

Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view

EN

EN

ru

ru