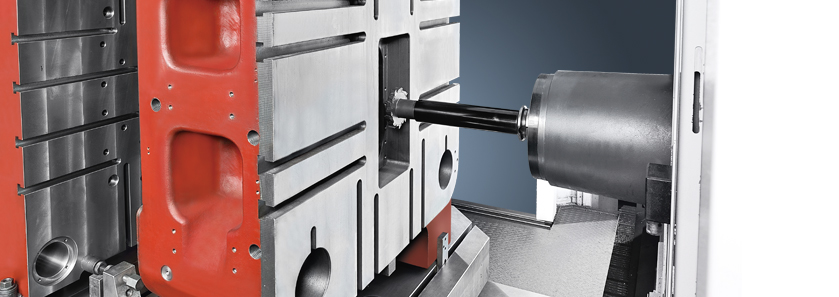

Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy. These machines operate on the principle of rotating cutting tools, facilitating precise material removal in horizontal planes.

The intricate process begins with the selection of appropriate tools and equipment, followed by meticulous planning to ensure precise execution. Horizontal boring's essence lies in its ability to cater to diverse industries, including aerospace, automotive, and manufacturing, where precision and accuracy are paramount.

Horizontal boring machines operate through a spindle that holds cutting tools, allowing for multi-directional movement to achieve precise results. The utilization of rotary cutters, along with coolant systems, maintains optimal tool temperature, enhancing precision and prolonging tool life.

Unparalleled Precision: Horizontal boring ensures pinpoint accuracy, making it ideal for applications requiring high tolerances and intricate designs.

Versatility Across Materials: Its adaptability across various materials, from metals to composites, expands its application range significantly.

Efficiency in Large-scale Operations: The capability to handle large workpieces efficiently distinguishes horizontal boring in manufacturing.

Selecting the right machine involves evaluating factors like spindle size, table size, and tool capacity. High-quality machines with advanced features enhance productivity and accuracy, reducing operational costs in the long run.

| Machine Model | Spindle Size (mm) | Table Size (mm) | Tool Capacity |

|---|---|---|---|

| XYZ-2000 | 150 | 2000x1200 | 12 |

| ABC-3000 | 180 | 2500x1500 | 16 |

| LMN-4000 | 200 | 3000x1800 | 20 |

These specifications showcase the diversity available in horizontal boring machines, allowing businesses to choose machines tailored to their specific needs.

As we navigate the intricate world of horizontal boring technology, a crucial aspect emerges — the comparative analysis between horizontal and vertical drilling methods. Each method possesses unique attributes, influencing their applicability across various industries and scenarios.

Horizontal drilling, with its multi-directional capabilities, stands out in scenarios where precision across a horizontal plane is paramount. In contrast, vertical drilling caters to different requirements, excelling in tasks demanding depth. Understanding these distinctions is crucial for selecting the optimal drilling method based on project specifications.

Precision in Horizontal Drilling: Horizontal boring's ability to achieve precise results across large workpieces makes it indispensable in CNC machining for intricate components.

Vertical Drilling's Depth Advantage: Vertical drilling, with its emphasis on depth, proves invaluable in applications such as well drilling and geological exploration.

Horizontal boring mills offer versatility in CNC machining, allowing for the production of complex components with superior precision. The horizontal orientation facilitates the efficient machining of multiple faces without repositioning the workpiece, optimizing workflow and minimizing setup times.

| Criteria | Horizontal Drilling | Vertical Drilling |

|---|---|---|

| Precision | High | Moderate |

| Depth Capability | Limited | High |

| Workpiece Size | Large | Small to Medium |

| Setup Complexity | Low | High |

Understanding these criteria enables informed decision-making when selecting drilling methods, ensuring alignment with project requirements.

Understanding the operational intricacies of horizontal boring is paramount for seamless execution. Let's delve deeper into the step-by-step guide, shedding light on the key stages and considerations for successful horizontal boring operations.

Effective planning is the cornerstone of successful horizontal boring operations. This phase involves meticulous blueprint analysis, identifying key parameters such as bore diameter, depth, and tolerances. Selecting the appropriate cutting tools, workholding fixtures, and setting up coolant systems are critical preparatory steps.

Once planning is complete, the next phase involves the setup of the horizontal boring machine. This includes aligning workpieces precisely, securing them firmly on the table, and adjusting machine settings to ensure optimal cutting conditions. Calibration of spindle speed, feed rate, and coolant flow is imperative for achieving desired results.

Choosing the right cutting tools based on material specifications and machining requirements is pivotal. Employing carbide inserts or high-speed steel tools, depending on the material being machined, guarantees efficient material removal while maintaining accuracy.

During the machining process, continuous monitoring is essential to ensure accuracy and prevent deviations. Periodic checks for tool wear, dimensions, and surface finish uphold the quality standards throughout the operation.

Upon completion of the bore, performing finishing operations, such as deburring and surface treatment, ensures the desired final product quality. Rigorous quality checks using measuring instruments validate dimensional accuracy and adherence to specifications.

| Operational Stage | Key Considerations |

|---|---|

| Planning and Setup | Blueprint Analysis, Tool Selection, Workholding Fixtures |

| Machine Setup | Alignment, Calibration, Machine Settings |

| Tool Selection | Cutting Tool Choice, Material Compatibility |

| Execution | Continuous Monitoring, Dimensional Checks |

| Finishing Touches | Deburring, Surface Treatment, Quality Assurance |

This table outlines the critical stages and considerations within horizontal boring operations, ensuring a systematic approach to achieve precision and efficiency.

Exploring the practical applications of horizontal boring technology illuminates its significance in various industries. Richconn's specialized Precision Machining services harness this technology's potential to deliver precision-engineered solutions across diverse sectors.

In the aerospace industry, where stringent quality standards prevail, Richconn's horizontal boring expertise shines. From manufacturing intricate components for aircraft engines to crafting precision parts for aerospace structures, the precision and reliability of horizontal boring technology are indispensable.

In the automotive sector, where efficiency and accuracy are paramount, Richconn's horizontal boring services play a pivotal role. Precision-crafted engine components and transmission parts are prime examples of how horizontal boring technology elevates automotive manufacturing capabilities.

For heavy machinery fabrication, Richconn's horizontal boring proficiency ensures the creation of robust and precisely engineered components. From gearboxes to specialized machinery parts, the accuracy achieved through horizontal boring technology enhances performance and durability.

| Industry | Application |

|---|---|

| Aerospace | Engine Components, Structural Parts |

| Automotive | Engine Parts, Transmission Components |

| Heavy Machinery | Gearboxes, Specialized Machinery Parts |

This table highlights the diverse applications of horizontal boring technology across industries, underscoring its versatility and adaptability.

Richconn's commitment to excellence extends to its specialized horizontal boring services. Leveraging cutting-edge horizontal boring machines and a team of skilled professionals, Richconn offers tailored solutions meeting precise client requirements.

The company's expertise spans from consulting on project specifications to executing complex machining tasks, ensuring impeccable results and client satisfaction.

2024 China (Shenzhen) International Industrial Parts Exhibition (CIIPES-2024)January 3, 2024Exhibition OverviewIn order to further enhance the development of the industrial parts industry, fully display the cutting-edge equipment technology of the industrial parts industry, actively promote ...view

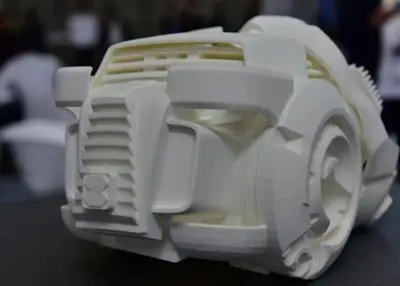

2024 China (Shenzhen) International Industrial Parts Exhibition (CIIPES-2024)January 3, 2024Exhibition OverviewIn order to further enhance the development of the industrial parts industry, fully display the cutting-edge equipment technology of the industrial parts industry, actively promote ...view The Beginner's Guide to the 3D Printing ProcessMay 5, 2024This article explains what 3D printing is, the materials it uses, its advantages, processes and techniques, applications, and more. Read on and get the best custom 3D printing services.view

The Beginner's Guide to the 3D Printing ProcessMay 5, 2024This article explains what 3D printing is, the materials it uses, its advantages, processes and techniques, applications, and more. Read on and get the best custom 3D printing services.view Machined Bearings Basics and Working PrinciplesNovember 9, 2023Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.view

Machined Bearings Basics and Working PrinciplesNovember 9, 2023Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.view Wire EDM: Analyzing Precision Cutting TechnologyNovember 16, 2023The field of machining covers a variety of complex processes, of which wire EDM is an important one. This precision cutting method processes electrically conductive materials into high-precision parts by means of electric spark discharge. In this article, we will take an in-depth look at the working principles of wire EDM, its areas of application and its importance in manufacturing.view

Wire EDM: Analyzing Precision Cutting TechnologyNovember 16, 2023The field of machining covers a variety of complex processes, of which wire EDM is an important one. This precision cutting method processes electrically conductive materials into high-precision parts by means of electric spark discharge. In this article, we will take an in-depth look at the working principles of wire EDM, its areas of application and its importance in manufacturing.view Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view

Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view Common Inspection Tools and Methods for CNC Parts: Ensuring Quality and PrecisionJune 21, 2024Learn about common inspection tools and methods in CNC machining, such as calipers, micrometers, gauges, projectors, and CMM. Discover how to use these tools accurately for quality control.view

Common Inspection Tools and Methods for CNC Parts: Ensuring Quality and PrecisionJune 21, 2024Learn about common inspection tools and methods in CNC machining, such as calipers, micrometers, gauges, projectors, and CMM. Discover how to use these tools accurately for quality control.view

EN

EN

ru

ru