※ Production time as short as 1 day.

※ High-precision 3D printed components.

※ Industry-leading 3D printers.

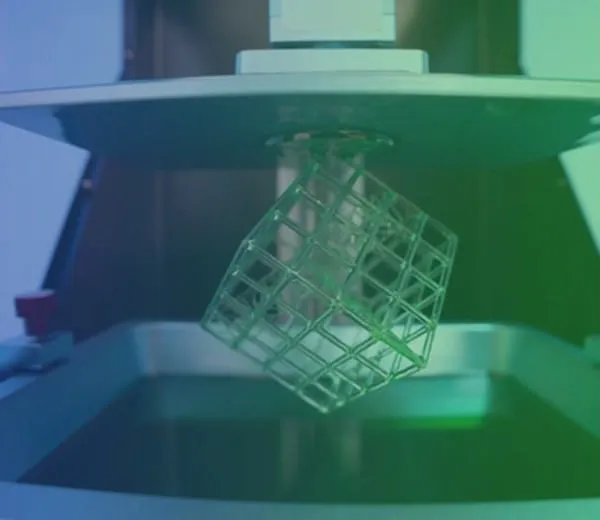

Stereolithography (SLA) is a powerful 3D printing technology that produces extremely accurate and high-resolution parts that can be used directly for end-use, low-volume production, or rapid prototyping as fast as one-day production.Richconn offers more than 15 uniquely-designed SLA materials to bring products to market.

Simply provide us with your CAD files, and we will respond quickly with pricing and manufacturability within 24 hours.

Thanks to our industry-leading equipment and skilled labor, we can quickly manufacture 3D parts from prototype to large production runs.

ISO9001 certified, Richconn manufactures 3D parts that consistently meet international standards, giving our customers peace of mind.

Richconn offers a wide range of stereolithography services, from CAD data design to production and post-processing, and more. We utilize state-of-the-art 3D printers to produce stereolithography parts with high precision and short turnaround times in 1 working day, and our experienced engineers are experts in stereolithography technology who will provide the best solutions and professional advice for your 3D printing projects to ensure that they can be executed successfully.

We aim to provide our customers with the best 3D printing resin service, our ISO9001 certified factory and standardized printing workflow ensures the quality of our products, and we have a proficient and friendly sales team that can respond quickly to internal customers with instant quotes 24 hours a day.

High Accuracy

Richconn offers stereolithography services to create very precise and beautiful 3D parts for our customers. With sizes ranging from a few millimeters to a meter, MOKO guarantees high precision and resolution regardless of size. There is virtually no shrinkage or warping of the part.

High Grade

Richconn uses industry-leading SLA printers to continually upgrade our stereolithography technology, ensuring that our stereolithographed parts have excellent surface finishes and mall feature definition. Our customers have no quality issues because of our strict quality control process. We are able to deliver 3D components as fast as one business day.

Multiple Material Options

Richconn stereolithography services offer a wide range of materials to choose from. The application of your project will determine what material should be used, and we are well positioned to serve customers from a wide range of industries. If you're not sure which material is best for your project, you can speak with one of our engineers who have extensive experience in this area.

SLA is an additive manufacturing process that uses ultraviolet (UV) light on a liquid photosensitive polymer resin barrel to selectively cure part features, building the part layer by layer. UV light continues the process through the entire resin barrel, selectively curing and solidifying the resin to match the CAD file design. Structural supports are created during the pre-build setup process and manually removed after printing is complete. The part is then washed in a solvent solution to remove uncured resin, followed by final post-curing in a UV light oven.SLA offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine detail and surface finish.SLA 3D printing is a highly versatile platform for manufacturing custom parts in both prototyping and production environments, and often serves as an injection molding parts.

With a wide range of suitable materials and fast turnaround times, stereolithography is an ideal tool for a variety of manufacturing industries, even for complex mesh shapes. It is primarily used in automotive engineering because it can cost-effectively produce complex parts with a variety of surface finishes and fine details. Parts can be embossed or engraved with matte, natural and countless other finishes depending on manufacturing requirements. While the primary success of stereolithography has been in providing rapid prototyping and design assistance to the automotive industry, stereolithography is rapidly being adopted on a large scale in a variety of mechanical modeling areas.

EN

EN

ru

ru