Metals are one of the most important materials in human history. They have been used for various purposes, such as tools, weapons, coins, jewelry, art, and construction. Metals can be classified into two main categories: ferrous and non-ferrous metals.

Ferrous metals are metals that contain iron as a major component. Examples of ferrous metals are steel, stainless steel, cast iron, and wrought iron. Examples of ferrous metals are steel, stainless steel, cast iron, and wrought iron. Non-ferrous metals are metals that do not contain iron as a major component. The main difference between ferrous and non-ferrous metals is the presence of iron. Iron is a magnetic element that can affect the properties and applications of metals. Iron can also react with oxygen and water to form rust, which can degrade the quality and durability of metals.

Ferrous metals have some common characteristics that make them distinct from non-ferrous metals. One of the most obvious characteristics is their magnetic property. Ferrous metals are usually magnetic, which means they can be attracted by magnets or generate magnetic fields. This property can be useful for some applications, such as electric motors, generators, transformers, and electromagnets.

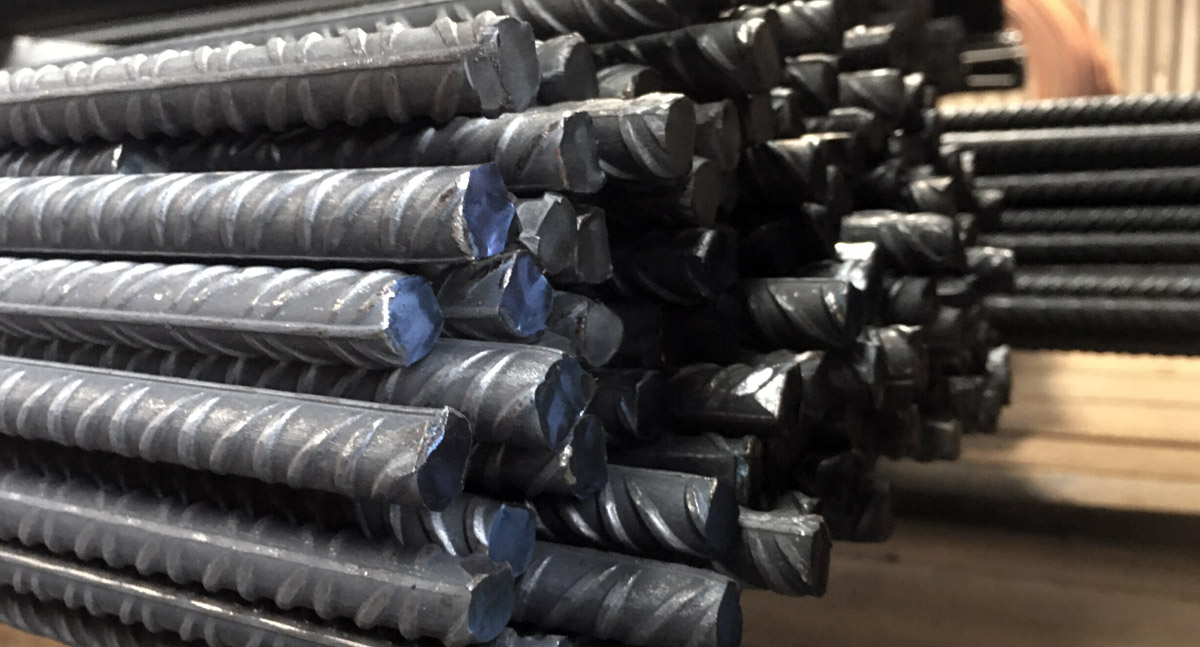

Another characteristic of ferrous metals is their strength and hardness. Ferrous metals are generally strong and hard, which means they can withstand high pressure, tension, and hardness. Another characteristic of ferrous metals is their strength and hardness. Ferrous metals are generally strong and hard, which means they can withstand high pressure, tension, and impact. This property can be useful for some applications, such as bridges, buildings, railways, and vehicles .

However, ferrous metals also have some drawbacks that limit their applications. One of the major drawbacks is their tendency to rust. is a reddish-brown substance that forms when iron reacts with oxygen and water. Rust can corrode and weaken the metal, reducing its quality and durability. Rust can also affect the appearance and performance of the metal.

Another drawback of ferrous metals is their weight. Ferrous metals are generally heavy, which means they require more energy and resources to transport and process. This can increase the cost and environmental impact of using ferrous metals.

The properties of ferrous metals can be affected by the iron content and the addition of other elements. The iron content can determine the degree of magnetism, rusting, and the amount of rusting. The iron content can determine the degree of magnetism, rusting, and weight of the metal. The addition of other elements can modify the properties of the metal, such as increasing or decreasing its strength, hardness, and weight. The addition of other elements can modify the properties of the metal, such as increasing or decreasing its strength, hardness, ductility, or resistance to corrosion.

Steel: Steel is an alloy of iron and carbon, with a small amount of other elements. Steel is one of the most widely used ferrous metals, due to its high strength, hardness, and versatility. Steel can be further classified into different grades and types, such as carbon steel, alloy steel, stainless steel, and tool steel. Steel can be further classified into different grades and types, such as carbon steel, alloy steel, stainless steel, and tool steel.

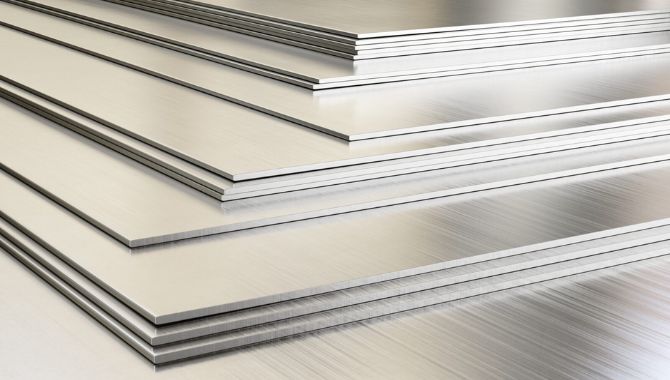

Stainless steel: Stainless steel is a type of steel that contains chromium, nickel, and other elements. Stainless steel is resistant to rust and corrosion, due to the fact that the steel has a high strength, hardness, and versatility. Stainless steel is resistant to rust and corrosion, due to the formation of a thin layer of chromium oxide on the surface. Stainless steel is used for applications that require hygiene, aesthetics, or durability, such as kitchenware, medical equipment, jewelry, and architecture.

Cast iron: Cast iron is an alloy of iron and carbon, with a high carbon content. Cast iron is brittle and hard, but also has good resistance to wear and heat. Cast iron is used for applications that require high strength and durability, such as engine blocks, pipes, cookware, and machinery.

Wrought iron: Wrought iron is an alloy of iron and carbon, with a low carbon content. Wrought iron is ductile and malleable, but also has good resistance to corrosion and fatigue. Wrought iron is ductile and malleable, but also has good resistance to corrosion and fatigue. Wrought iron is used for applications that require decorative or artistic features, such as gates, fences, railings, and furniture.

Non-ferrous metals have some common characteristics that make them distinct from ferrous metals. One of the most obvious characteristics is their non-magnetic property. One of the most obvious characteristics is their non-magnetic property. Non-ferrous metals are usually non-magnetic, which means they are not attracted by magnets or generate magnetic fields. This property can be useful for some applications, such as electronic devices, sensors, and MRI machines.

Another characteristic of non-ferrous metals is their light weight and malleability. Non-ferrous metals are generally light and malleable, which means they can be used for a variety of purposes. Another characteristic of non-ferrous metals is their light weight and malleability. Non-ferrous metals are generally light and malleable, which means they can be easily shaped, bent, or cut. This property can be useful for some applications, such as aircraft, spacecraft, cans, and foil.

However, non-ferrous metals also have some drawbacks that limit their applications. One of the major drawbacks is their low strength and hardness. However, non-ferrous metals also have some drawbacks that limit their applications. One of the major drawbacks is their low strength and hardness. This property can limit their use for some applications, such as structural or heavy-duty components.

Another drawback of non-ferrous metals is their high cost and scarcity. Non-ferrous metals are generally more expensive and less abundant than ferrous metals, which are more expensive than ferrous metals. Non-ferrous metals are generally more expensive and less abundant than ferrous metals, which means they require more resources and energy to produce and process. This can increase the economic and environmental impact of using non-ferrous metals.

The properties of non-ferrous metals can be affected by the absence of iron and the addition of other elements. The absence of iron can determine the degree of non-magnetism. The absence of iron can determine the degree of non-magnetism, lightness, and malleability of the metal. The addition of other elements can modify the properties of the metal, such as increasing or decreasing its strength. The addition of other elements can modify the properties of the metal, such as increasing or decreasing its strength, hardness, conductivity, or resistance to corrosion.

Aluminum: Aluminum is a metal that contains aluminum as the main component. Aluminum is one of the most widely used non-ferrous metals, due to its low density, high ductility, and low cost. Aluminum is one of the most widely used non-ferrous metals, due to its low density, high ductility, and good conductivity. Aluminum can be further classified into different grades and types, such as pure aluminum, alloy aluminum, and recycled aluminum. Aluminum can be further classified into different grades and types, such as pure aluminum, alloy aluminum, and recycled aluminum.

Copper: Copper is a metal that contains copper as the main component. Copper is one of the most versatile non-ferrous metals, due to its high conductivity, thermal conductivity, and good conductivity. Copper is one of the most versatile non-ferrous metals, due to its high conductivity, thermal conductivity, and corrosion resistance. Copper can be further classified into different grades and types, such as pure copper, alloy copper, and bronze. Copper can be further classified into different grades and types, such as pure copper, alloy copper, and bronze.

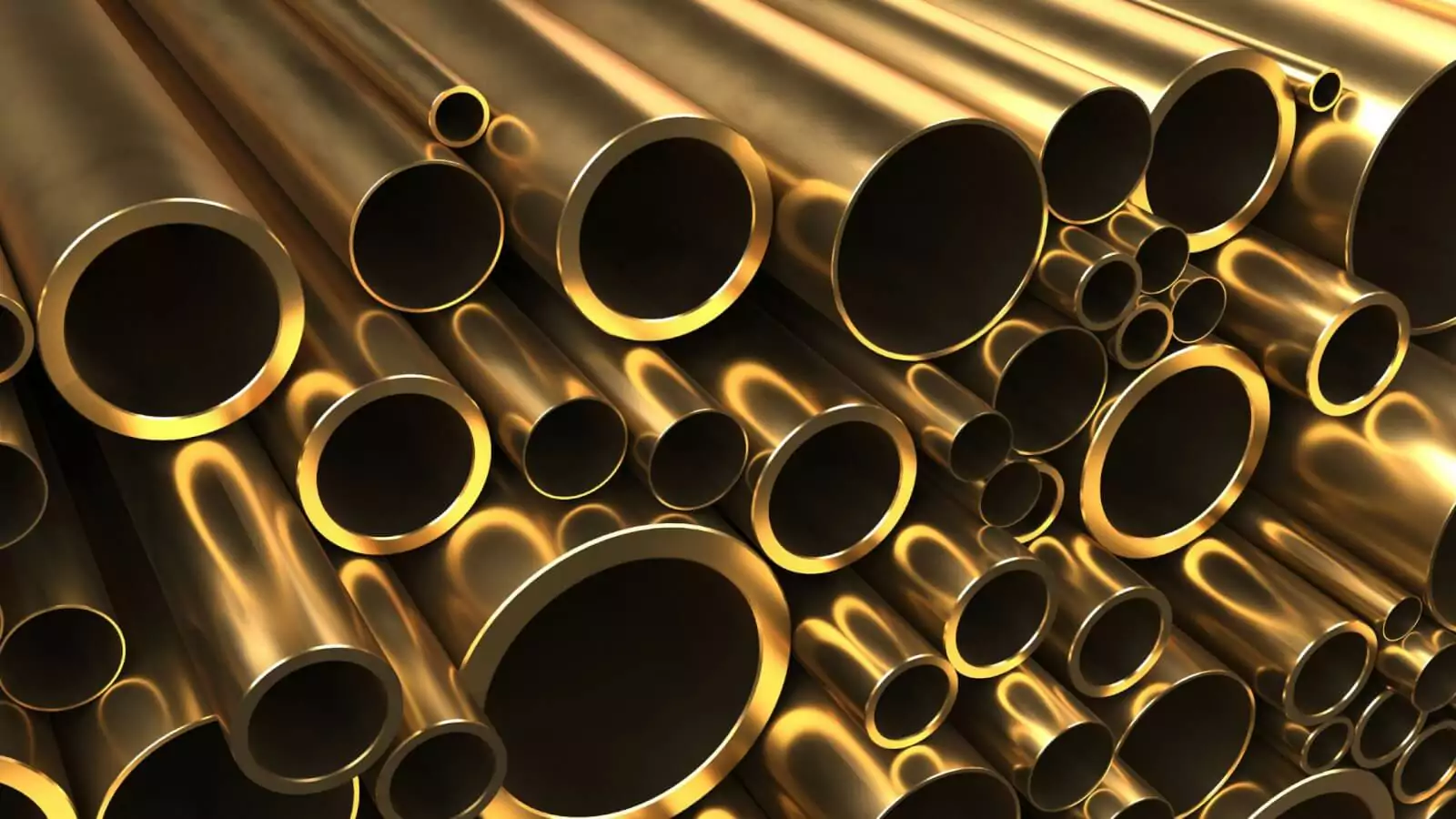

Brass: Brass is an alloy of copper and zinc, with a small amount of other elements. Brass is a type of non-ferrous metal that has a golden color, good malleability, and moderate resistance. Brass is a type of non-ferrous metal that has a golden color, good malleability, and moderate strength. Brass is used for applications that require decorative or musical features, such as ornaments, coins, instruments, and valves. Brass is used for applications that require decorative or musical features, such as ornaments, coins, instruments, and valves.

Titanium: Titanium is a metal that contains titanium as the main component. Titanium is a type of non-ferrous metal that has a silver color, high strength, and low density. Titanium is a type of non-ferrous metal that has a silver color, high strength, and low density. Titanium is used for applications that require high performance or biocompatibility, such as aerospace, medical, and sports equipment. applications of Ferrous Metals

Ferrous metals are used for various applications in different industries and sectors, due to their properties and characteristics. Some of the main uses of ferrous metals are in the manufacture of metal products. Some of the main uses of ferrous metals are: Construction: Ferrous metals are used in a variety of applications in different industries and sectors, due to their properties and characteristics.

Construction: Ferrous metals are used for construction purposes, such as building structures, foundations, frames, and reinforcements. Ferrous metals provide strength, stability, and durability for the construction projects. Examples of ferrous metals used for construction are steel, stainless steel, and stainless steel. Examples of ferrous metals used for construction are steel, stainless steel, and cast iron.

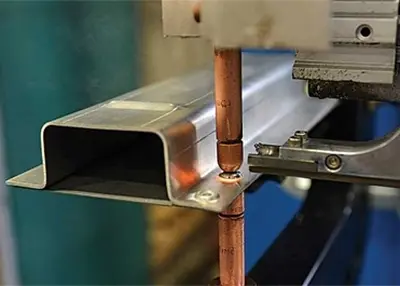

Manufacturing: Ferrous metals are used for manufacturing purposes, such as producing machines, tools, equipment, and components. Ferrous metals provide hardness, wear resistance, and heat resistance for the manufacturing processes. Examples of ferrous metals used for manufacturing are steel, stainless steel, and cast iron. Examples of ferrous metals used for manufacturing are steel, stainless steel, and tool steel.

Transportation: Ferrous metals are used for transportation purposes, such as creating vehicles, railways, ships, and airplanes. Ferrous metals provide strength, toughness, and impact resistance for the transportation modes. Examples of ferrous metals used for transportation are steel, stainless steel, and tool steel. Examples of ferrous metals used for transportation are steel, stainless steel, and cast iron.

Tools: Ferrous metals are used for tool purposes, such as making knives, scissors, hammers, and wrenches. Ferrous metals provide Ferrous metals provide sharpness, durability, and magnetism for the tool functions. Examples of ferrous metals used for tools are steel, stainless steel, and wrought iron.

Non-ferrous metals are used for various applications in different industries and sectors, due to their properties and characteristics. Some of the main uses of non-ferrous metals are: Electronics: Non-ferrous metals are used in a variety of applications in different industries and sectors, due to their properties and characteristics.

Electronics: Non-ferrous metals are used for electronic purposes, such as creating devices, circuits, wires, and connectors. ferrous metals provide conductivity, thermal conductivity, and non-magnetism for the electronic functions. Examples of non-ferrous metals used for electronics are copper, aluminum, and brass. Examples of non-ferrous metals used for electronics are copper, aluminum, and brass.

Aerospace: Non-ferrous metals are used for aerospace purposes, such as creating aircraft, spacecraft, rockets, and satellites. Non-ferrous metals provide light weight, high performance, and low cost. Non-ferrous metals provide light weight, strength, and corrosion resistance for the aerospace modes. Examples of non-ferrous metals used for aerospace are aluminum, titanium, and nickel. Examples of non-ferrous metals used for aerospace are aluminum, titanium, and nickel.

Jewelry: Non-ferrous metals are used for jewelry purposes, such as making rings, earrings, necklaces, and bracelets. Non-ferrous metals provide aesthetics, malleability, and aesthetic appeal. metals provide aesthetics, malleability, and durability for the jewelry features. Examples of non-ferrous metals used for jewelry are gold, silver, and platinum. Examples of non-ferrous metals used for jewelry are gold, silver, and platinum.

Art: Non-ferrous metals are used for art purposes, such as making sculptures, statues, paintings, and coins. Non-ferrous metals provide color, texture, and creativity. Non-ferrous metals provide color, texture, and creativity for the art expressions. Examples of non-ferrous metals used for art are copper, bronze, and zinc.Examples of non-ferrous metals used for art are copper, bronze, and zinc.

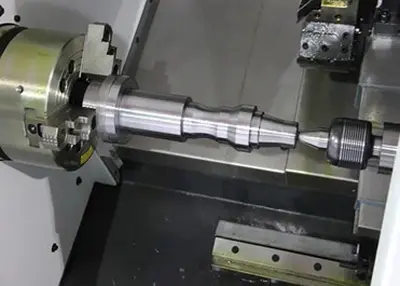

The main difference between ferrous and non-ferrous metals is the presence of iron. Iron is a magnetic element that can affect the properties and applications of metals. Iron can also react with oxygen and water to form rust, which can degrade the quality and durability of metals.Looking for a ferrous and non-ferrous precision machining service provider? Richconn is an excellent choice whether you need to machine ferrous or non-ferrous metals. We have the experience and expertise to provide you with quality CNC machining services. Whether your project requires steel, aluminum, copper, or other non-ferrous metals, Richconn can provide quality machining solutions.

What is a CNC machine? The Precision Way to Modern ManufacturingSeptember 21, 2023CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program.view

What is a CNC machine? The Precision Way to Modern ManufacturingSeptember 21, 2023CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program.view Excellent Corrosion Resistance of Stainless Steel-316L Stainless SteelOctober 24, 2023Dear viewers, today we are going to talk about an amazing material - 316L stainless steel. Did you know? This ordinary-looking material has amazing corrosion resistance! 316L stainless steel as a low carbon series of 316 steel, in addition to the same characteristics with 316 steel, its resistance to grain boundary corrosion is excellent, let's take a look at it!view

Excellent Corrosion Resistance of Stainless Steel-316L Stainless SteelOctober 24, 2023Dear viewers, today we are going to talk about an amazing material - 316L stainless steel. Did you know? This ordinary-looking material has amazing corrosion resistance! 316L stainless steel as a low carbon series of 316 steel, in addition to the same characteristics with 316 steel, its resistance to grain boundary corrosion is excellent, let's take a look at it!view CNC Machining 101: What Are CNC Machining Services?August 11, 2023CNC machines have become increasingly popular in various industries due to their precision and efficiency. They are manufacturing different parts and fittings in a wide range of industries, such as au...view

CNC Machining 101: What Are CNC Machining Services?August 11, 2023CNC machines have become increasingly popular in various industries due to their precision and efficiency. They are manufacturing different parts and fittings in a wide range of industries, such as au...view How to Produce High-quality Parts With CNC?June 25, 2024The passage mainly talks about the production progress of high-quality parts with the help of CNC. It’s strongly recommended that Richconn is an effective company, which owns many technicians and advanced technology.view

How to Produce High-quality Parts With CNC?June 25, 2024The passage mainly talks about the production progress of high-quality parts with the help of CNC. It’s strongly recommended that Richconn is an effective company, which owns many technicians and advanced technology.view Exploring the World of High-Speed MachiningNovember 22, 2023In the ever-evolving landscape of manufacturing, the pursuit of efficiency and precision has led us to the realm of High-Speed Machining (HSM).view

Exploring the World of High-Speed MachiningNovember 22, 2023In the ever-evolving landscape of manufacturing, the pursuit of efficiency and precision has led us to the realm of High-Speed Machining (HSM).view The Differences Between Riveting vs WeldingFebruary 18, 2024Let's explore the advantages, applications, and limitations of riveting and welding processes. Then, you can select the right method for assembling sheet metal parts.view

The Differences Between Riveting vs WeldingFebruary 18, 2024Let's explore the advantages, applications, and limitations of riveting and welding processes. Then, you can select the right method for assembling sheet metal parts.view